quattro wrote:And one question about the necessary downforce.

If i assume a car weight of 750 kg (fuel and driver included), the weight of the car is the following:

L = mcar * g = 750 kg * 9,81 m/s² = 7357.5 N

So, with the fact that a rear wing produces approximately 30 % of the overall downforce, the from the wing created amount of this downforce should be approximately 2200 N.

So far my actual status. But now some other theoretical questions...

I read on wikipedia the following:

"while an F1 car achieves the same downforce:weight ratio of 1:1 at 125 km/h (78 mph) to 130 km/h (81 mph), and at 190 km/h (118 mph) the ratio is roughly 2:1.".

Thats actually the exact information i need, WHEN i have to produce the downforce ratio of 1:1 to the car weight. But what happens if the car is faster/slower than this amount?

Is it okay when i test the downforce at 125 km/h and i achieve a downforce ratio of 1:1? I'm not sure, but with the information that the wings are fixed for each track, i guess that the magnitude of downforce adjusts itself if the wing has a downforce/weight ratio of 1:1 at a speed of 125 km/h?!

This is just the point where i struggle at the moment. For example, if there are lift producing parts on the formula one car, of course, the downforce creating parts have to create more downforce than just the weight.

Also a fact is that at higher speeds, the downforce should be much higher than just the car weight to achieve the needed grip on the track.

Therefore: am i okay if the downforce/weight ratio is about 1:1 at approx. 125 km/h?

I hope you can understand my problems, sorry, my English is not the best...

regards!

OK, if this is a semester project or senior design project, I wouldn't worry about total downforce just in the interest of time and resources. Your 125 km/hr figure for 1:1 downforce to weight ratio is probably close to reality. As for 30% of the downforce coming from the rear wing, that number is a little more difficult to assess considering that the aerodynamic downforce is not just a sum of the parts. The wings and underbody all work together, and the rear wing actually has a great effect on the air exiting the diffuser.

But if you feel that the 30% figure is a reasonable approximation (and you should justify that somehow, other than a wikipedia article of course...

), then it would be useful to use as a benchmark value to make sure you have a wing that is at least in the ballpark. That is, you are making an assumption that the rear wing will generate X amount of downforce at velocity Y. In your lift equation, L = 0.5*rho*V^2*A*C_L, you still need to determine A and C_L. If this is specifically for an F1 car, the A is partially defined by the rules. I know the span width of the wings is mandated, but I'm not sure about the chord length so you'll have to check. For the moment, we'll assume you can have any chord length you wish. So now you can set up a table with a variety of chord lengths as your input and the required C_L value to meet your lift requirement as the output. This should give you some direction in your airfoil search to determine what planform area and C_L are at least realistic to meet the benchmark goal.

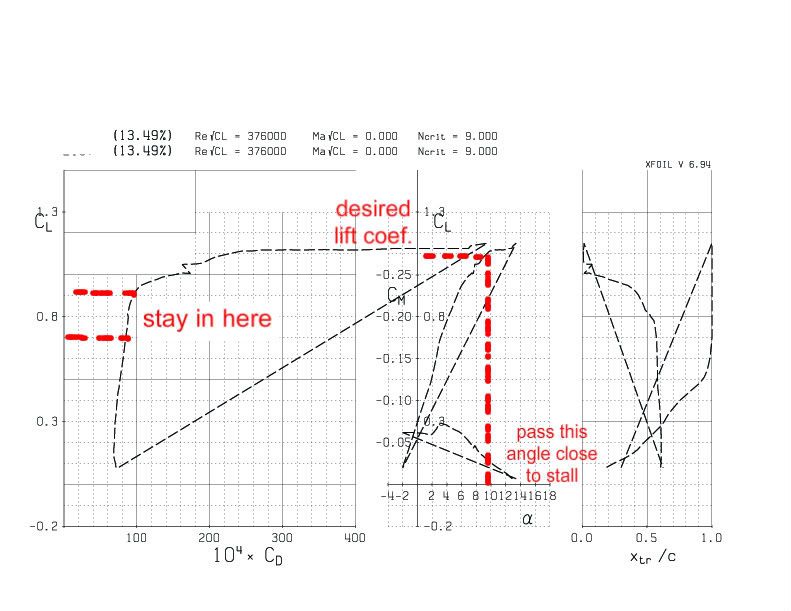

Once you have determined a few airfoil shapes that meet your benchmark requirement, I wouldn't think about total downforce, or any percentage of it, anymore. Since you are studying the rear wing only, you can't truly assess its effect on the whole car due to its interaction with the underbody. Rather, you can analyze how sensitive the wing is to changes in variables. There is no "perfect wing setup" in reality, but engineers do need to know the effect of changing wing angles, chord length, etc. So as a starting point you could analyze pitch sensitivity and speed sensitivity. Determine some range of angle of attack and velocity that you would consider an acceptable range, and break the range into a few discrete points for each. Then determine the C_L value each combination of velocity and angle of attack. So if, for example, you have 5 angle of attack points and 5 velocities, then you'll calculate 25 C_L values. You can then plot several C_L vs. AoA curves, one curve for each velocity. You can then repeat the process for the different airfoil shapes you picked earlier, and then compare and contrast the two.

One thing you might want to keep in mind is that the slope of the C_L vs. AoA curve is steeper for higher aspect ratio wings, and the max C_L increases with aspect ratio as well, so the chord length plays a major role in your C_L value. Once you have the speed/AoA study working you could consider adding the chord length as another variable. But don't bother with it initially. There will be some debugging in your process (there always is) so the fewer elements you have to mess up at the beginning, the easier it is to fix the problem.

Hopefully what I've said makes sense, but if it doesn't just let me know and I'll amplify what I mean. Good luck with the project...