Okay so for perspective, I have a conventional 2012 design, and my Inverted V design.

These images will show how much of a benefit it could offer, assuming that the more mass flow in this area, the better.

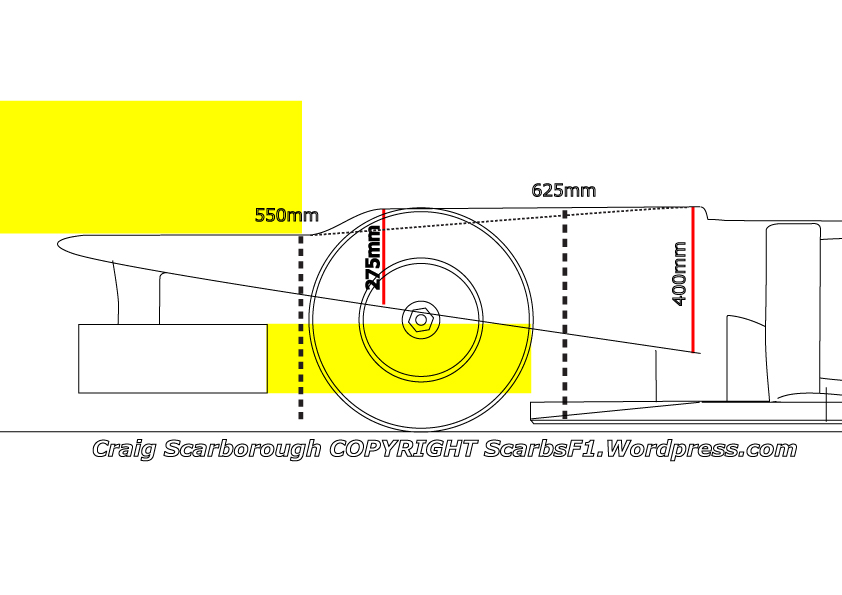

This first image shows dimensions, and how it meets the regulations, assuming that the maximum V allowed can be used at the bottom, instead of the top of the of the tub. It also shows that the tip is much higher, and that an ironing board flat top can be used on this style of nose. The red box above 550mm denotes the area where no bodywork is permitted.

The second image shows the two side by side. It really shows just how much more area can be gained by using this concept. Note that the suspension mount points (on the V ridges for the inverted V concept), remain in the same place although packaging of components may be flawed, causing a raised CofG over the conventional design.

For the third image, I coloured in the V ridges blue, so you can see a comparison along the majority of the width of the tubs.

The mass flow rate of the inverted V nose must surely be much higher than a conventional design. I have been led to believe that this is a benefit.