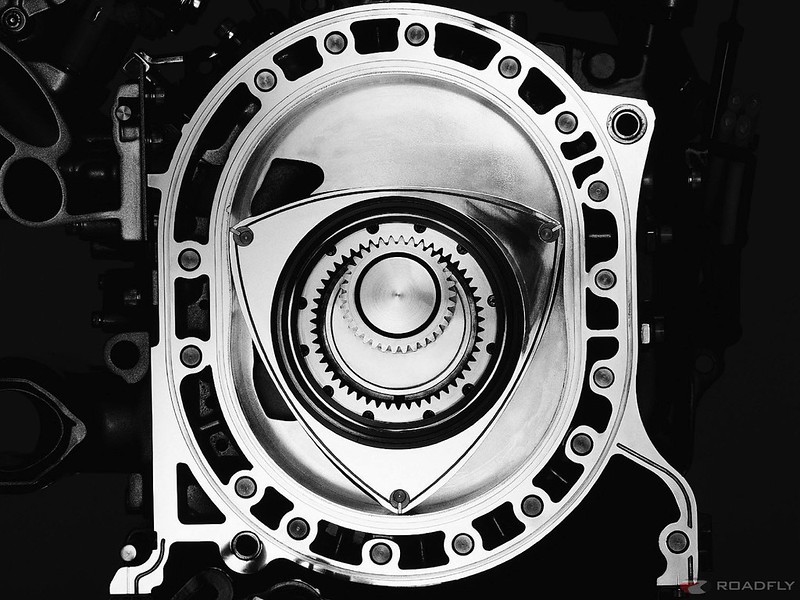

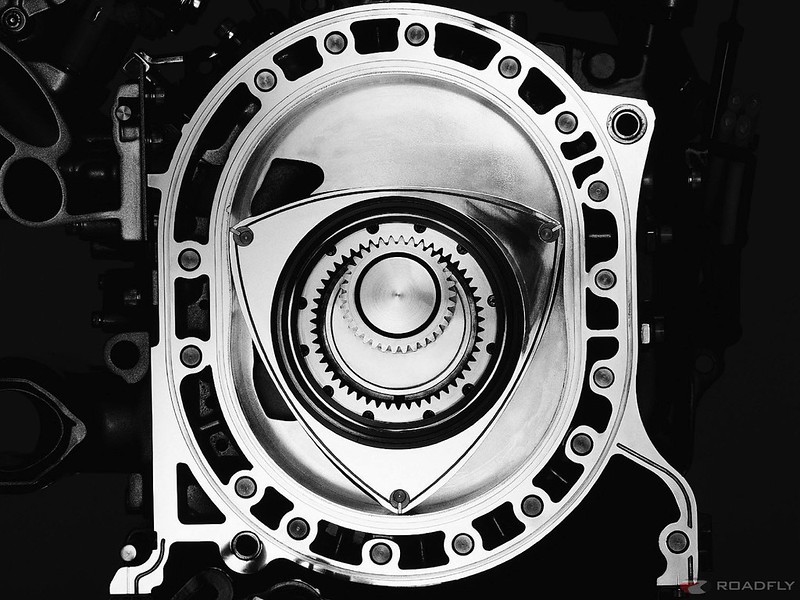

Look!!!.......a sealed rotary valve!!!

No, not the apex seals..............the side seals.

Talking about rotary valves here. Obviously a seated type of valve will only have one boundary for sealing so if that leaks it will show. That is not the case for multiple seals.hardingfv32 wrote:This is incorrect. The slightest leak at a poppet valve seat can be observed on the dyno as a loss of performance.n smikle wrote:... If your sealing gap (if there is one at all) is small enough and if there is another row of sealing especially the gasses will have to slow down to extremely slow speeds to even pass through, it is almost like the flow has to be laminar! That is asking alot from a big flaming ball of fire in the combustion chamber...

Brian

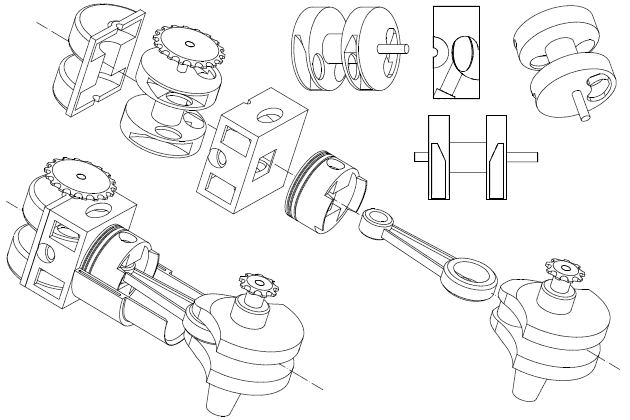

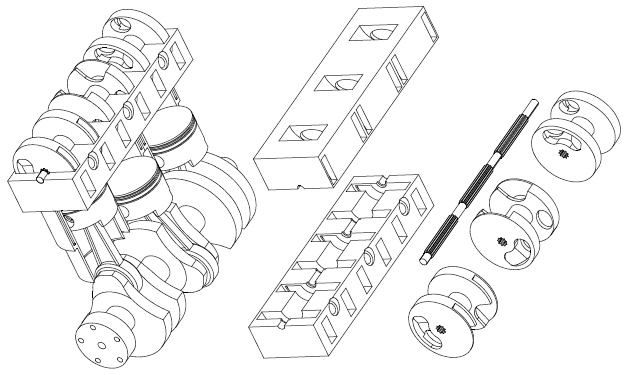

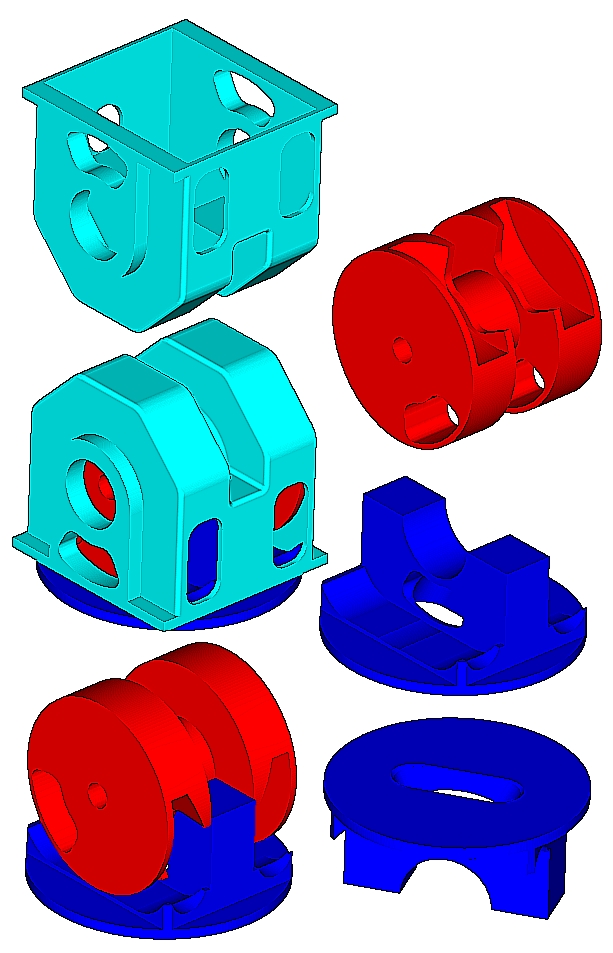

I 'm not so familiar with 2 stroke engines for go-karts and bikes alike... but i have known that some use reeds and some use rotary valves.. what is different about your design versus the common design?uniflow wrote:Here is a ball valve. Note the piston ring groove, works as if it's in a bore. This valve is hollow for cooling.

http://i1056.photobucket.com/albums/t38 ... 9d7448.jpg