wuzak wrote:aleks_ader wrote:Also they could move MGU-H inside clutch bell with drop gear assembly... Like they did with ERS-K or MGU-K. Then you move oil tank in common position infront engine and redesign clutc&bell case to accommodate structure to the free space and its relocated "bigger" turbo assembly. Also that you coul literally feed ERS-H direct into ERS-K (+ CE off-course). A lot of IF...

I'm not sure that would be such a good move, because you're adding a side load into the turbo's shaft. The in-line solution would be better, with an epicyclic gearbox for speed reduction.

Excellent!

Off-course that would be the main problem, but who said it would be easy.

Between friends we also discussed about ceramics ball bearings of the turbo shaft (they could easily handle 200 kRPM).

So the additional loading could be "redefined" with recalculation of size of bearings, adding clever damping&clutch elements and the redesign shaft diameter (to maintain the "centering" and avoid critical rotational RPM of the shaft).

But at the same time you make pros:

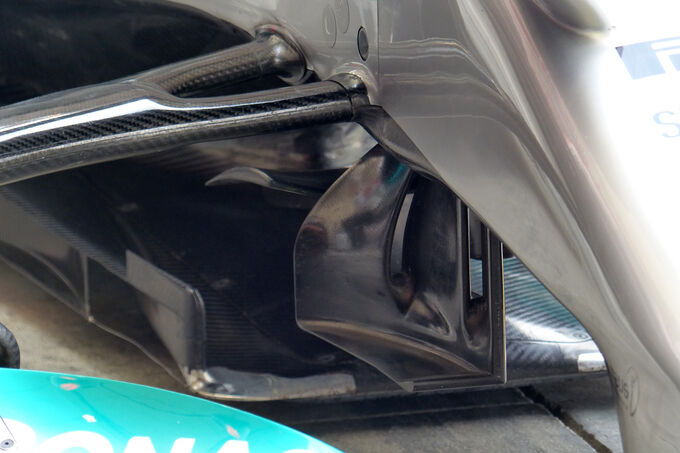

1. coke bottle is much more tighter and narrower (no compromise to make longer wheelbase or smaller turbine dia=30mm room to resize),

2. lowers the CofG, less stress on top of the cover (less weight to support complete exhaust and waste-gate assembly),

3. improve cooling of the ERSA and MGU assembly. Colling became more effective and easier to control (also you could reduce cooling of MGU-H unit or do reverse trade-off and for same car "heat footprint" reduce the weight of MGU)

4. possibility of the direct E-link toward ERS-K

5. Overall packaging of the back of the engine and clutch-bell became much more evenly distributed.

6. Exhaust could became much shorter, hence lees weight (200 mm for sure)

cons:

a. without clutched assembly the TURBO unit response could be seriously compromised due additional rotational inertia, lag could be even worse; adding the clutch make the assembly a heck more difficult + heavier

b. added additional side load due gear meshing =reduced life of the TURBO unit, redesign needed described above

c. additional weight due additional bearings, gearings and housing (but maybe that could even out with point no. 2)

d. add mesh losses, accordingly drop gear meshing max 5%

d. the oil tank need to be relocated, so 1 token for "oil ancillaries" is wasted

"And if you no longer go for a gap that exists, you're no longer a racing driver..." Ayrton Senna