Hello Muniix

A few months ago, in our private communication (via e-mails), you made, among others, some estimations / prediction / rough calculations about the poor flow characteristics of the PatRoVa.

You insisted.

After 25 replying e-mails to you, and being tired / exhausted to repeat the same “simpleminded” things, I proposed you to bet on your predictions.

Please, do publish the e-mail of January 13, 2017 (and the rest ones, if you like so).

I am sure the members of this forum discussion will enjoy it.

I have spent several hours reading the patents granted (or filed but not granted) to the guys of the multi-million Bishop team.

I admit I failed to understand the way the sealing means of the Bishop rotary valve are lubricated: just like the piston rings of the conventional 2-strokes they pass over big holes (the intake and exhaust ports on the Cross-Bishop rotary valve), yet they don’t leave any lubricant to get into the combustion chamber or to be lost towards the exhaust.

As explained in previous posts, the theories about the “dry lubrication with the carbon particles of the combustion” are not persuasive.

I also admit that I still do not get the real difference between the Bishop rotary valve and the original Cross rotary valve (or the rotary valve of Ralph Watson).

If anybody in this forum can explain, in simple words, their main difference, it would be great.

Your repeat writing the millions of dollars invested on (and lost by) the Bishop rotary valve project.

Here is a similar sad story:

For almost two decades EcoMotors was presenting in the press, in thousands of articles in paper magazines and in the web, their miraculous OPOC engine.

The founder of EcoMotors is Peter Hofbauer, a reputable auto industry engineer; his name can be found in some rotary engine (Wankel like) patents filed by the VW half a century ago.

Some of the investors of EcoMotors are regarded among the smartest guys in the world (Bill Gates, of Microsoft, invested 23.5 million dollars on the OPOC), not less smart than the investors of the Bishop rotary valve project.

The OPOC had the same basic problem with the Bishop rotary valve: they never address the lubrication issue.

The OPOC is based on the “total loss” lubrication of the conventional old 2-strokes.

The magazines around the world were publishing, again and again and again, the misleading promises of the EcoMotors board team (comprising big / known / reputable / successful names of the auto industry).

Somebody had to say “The king is necked”; the following comment of mine was published in “The knee slider” a few years ago:

“In EcoMotors they have the funds, they have the publicity (every time a guy in EcoMotors “coughs”, every magazine in the world publishes -or reproduces- an article for OPOC), they have the support (only the name of Bill Gates “opens” every door). What they don’t have is a good engine design.

Unless I am wrong, after several years there is not yet an OPOC in a car or truck for tests by an independent third party.

Get in the place of the independent inventors / researchers / makers and think how they feel seeing in the press, again and again and again, about the OPOC of EcoMotors, about how many parts less than the other engines it comprises (which is a false claim), about how many less fuel it will consume (which is also a false claim), about how “green” it will be (which is also a false claim), and so on.”

and predicts, more or less, the sad end of the story.

And what is the end of the story?

A few days ago I tried to visit the web site of the EcoMotors to see if they had some news.

And there is no web site, any longer.

The wikipedia has a complete page dedicated to the EcoMotors / OPOC and gives as “Official EcoMotors website” the:

http://www.ecomotors.com/ Try it.

It is sad.

100 million dollars, or so, were lost on the OPOC.

And now, nobody of all those famous / smart guys involved in the “great, promising, game-changing, etc, etc, OPOC engine project”, paid the required a hundred, or so, dollars (not thousands, just dollars) to keep the web site of EcoMotors alive / active.

In comparison, the PatOP engine project of pattakon has a total cost, so far, around 10,000 dollars (including the patenting, the manufacturing of the prototype etc), i.e. some 10,000 times lower than the cost of the EcoMotors OPOC project.

The PatOP engine solves several crucial problems not addressed by the famous EcoMotors OPOC engine.

The Wikipedia does not mention the PatOP engine, at all.

A few years ago I added, at the “External links” section, at the bottom of the EcoMotors OPOC web page in the wikipedia, a link to the PatOP engine; a few weeks later they deleted it (congratulations to the wikipedia for their censorship).

Today, anyone who needs information about the PatOP can look at

http://www.pattakon.com/pattakonPatOP.htm , or can communicate with the pattakon by e-mail, while nothing is now officially available in the web about the “promising” EcoMotors OPOC engine (nor it is possible to communicate with EcoMotors to ask anything).

Despite the many millions of dollars (as you like to write / repeat) invested in the Bishop rotary valve project (and the many famous and smart guys involved in the Bishop project), nothing is left.

Nothing at all.

Not one (just one) motorcycle having the Bishop rotary valve on the cylinder head for normal use or for road tests.

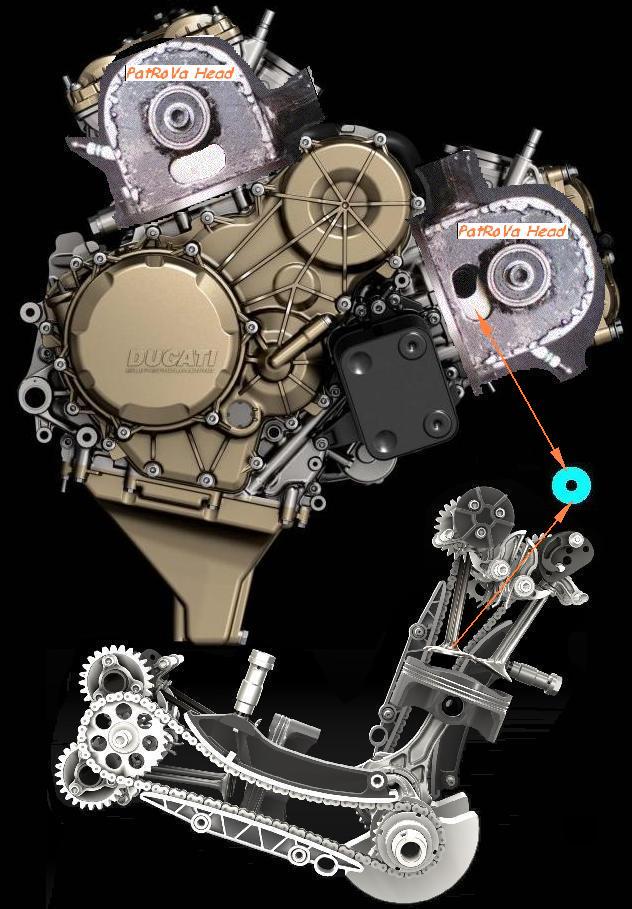

The PatRoVa rotary valve changes the game because it brings new and important characteristics not existing before.

The total force on the bearings of the PatRoVa rotary valve is zero.

Just zero.

No matter how high is the pressure in the combustion chamber.

And it needs no oil to lubricate heavily loaded sliding surfaces and sliding seals (the Achilles’ heel of the Bishop rotary valve for mass production / emission complied engines). Because there are not heavily loaded surfaces or seals in the PatRoVa.

As for its flow capacity, you should think “out of the box” to see how good it can be.

It becomes more obvious in the PatRoVa with the “tapered disks”:

two symmetrical tangential air streams (entering into the cylinder by the two symmetrically arranged chamber ports) move without affecting each other (each at its own half of the cylinder).

Like having “a ideal curtain” dividing the cylinder in two halves.

So, take another different look at the PatRoVa rotary valve.

And talking for “a different look”, did you achieve to look at the above animation stereoscopically?

Many people cannot look the proper way and instead of insisting, they think it cannot be done.

Thanks

Manolis Pattakos