Hello Muniix.

You write:

“I was talking about using gas pressure

as the sole means for seal force?

you did not answer that!

The PatRoVa has massive leakage which is equivelent to crevice volume, your whole valve housing is crevice volume.”

The answer is:

The PatRoVa rotary valve “is not using gas pressure for sealing”.

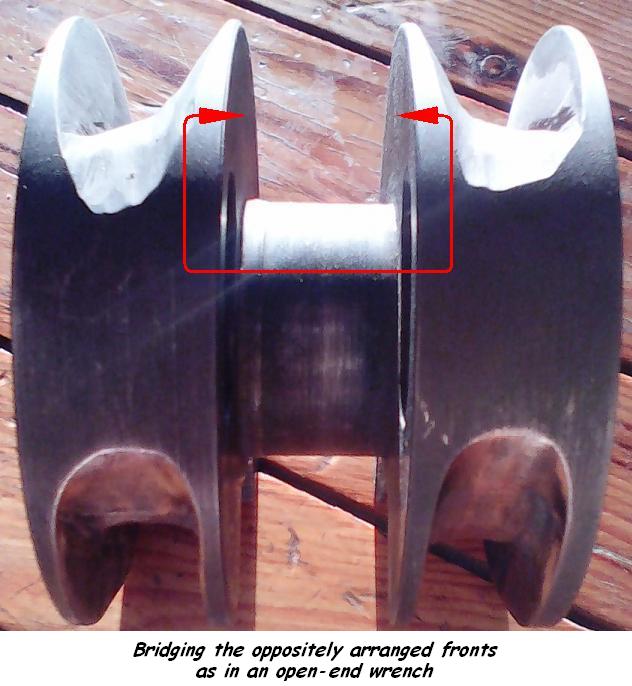

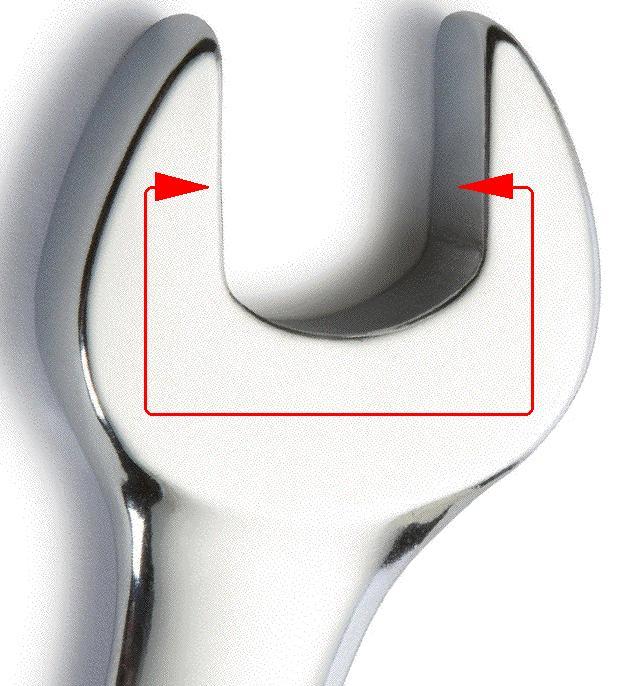

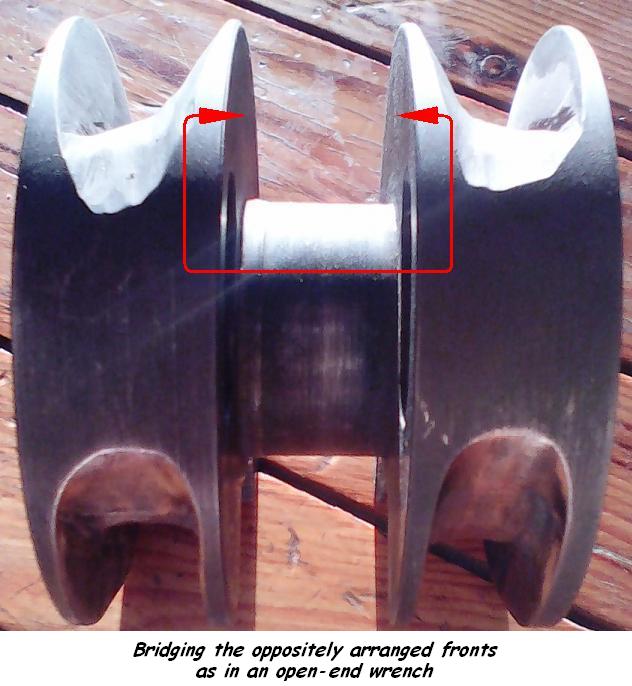

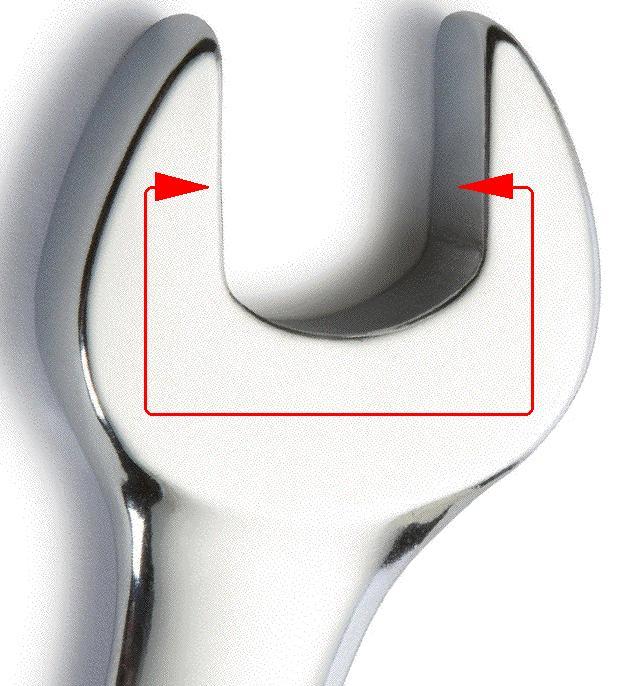

The PatRoVa rotary valve seals by keeping tiny the clearance between the chamber port lips and the opposite acting fronts of the rotary valve.

QUOTE from the beginning of the

http://www.pattakon.com/pattakonPatRoVa.htm web page:

“What the rotary valve does need is a very strong "body" to "connect" the oppositely acting fronts; so strong that the heavy loads applied on the fronts to cause no more than an insignificant deformation of the rotary valve and thereby to keep into the required strict limits the clearance between the chamber ports and the rotary valve fronts (wherein the sealing happens).

Accordingly, a rock-solid structure for the rotary valve is essential; but this is not an issue because the rotary valve performs a smooth rotation at half crankshaft speed; even a substantial increase of the rotary valve mass and inertia is tolerable; in comparison a small increase of the reciprocating mass of a poppet valve causes major side effects.”

END of QUOTE

You also write:

“As detailed you have too many inherent flaws in the design as previously raised, sealing, insufficient flow, loss of pressure wave action, increased pumping losses, thermal issues ....

Trying to solve the non issue of combustion pressure, you split the flows and turned them into one another.

Loosing valuable flow capacity and reducing the flow coefficient many times on an already low flow. Introducing fluid flow issuesj that only 3D CFD while allow you to understand, and it will be complex to implement the motions of the valve into the simulation.”

Are you ready to bet on what you claim?

You have my “bet” e-mail from January.

You also write:

“That is mischevious refering to an obsolete patent, lodged in for patent protecion, it can be used in motorsport, that one is not the latest sealing patents Bishop filed. Remember I gave you the latest one, Cameron Donalds patent. The one that solves all the issues with clever overlapping. It identifies all the issues that a sealing array must provide and addresses them providing everthing the seals need to do. It shows all the paths, and flows, and the mechanisms used to address them.”

Nonsense.

The “mischevious refering” is nothing more than what the inventors write in “their” US7,621,249 patent.

Are you representing the inventors or the assignee?

Are you authorized to classify Bishop patents in good ones and bad ones?

The “legacy” of the “Bishop Innovation Limited” is their patents. Don’t spoil it.

You claim you know the guys of the Bishop team.

If so, ask Anthony Bruce Wallis to get in this discussion.

Thanks

Manolis Pattakos