Thanks for the replies. On the sealing..

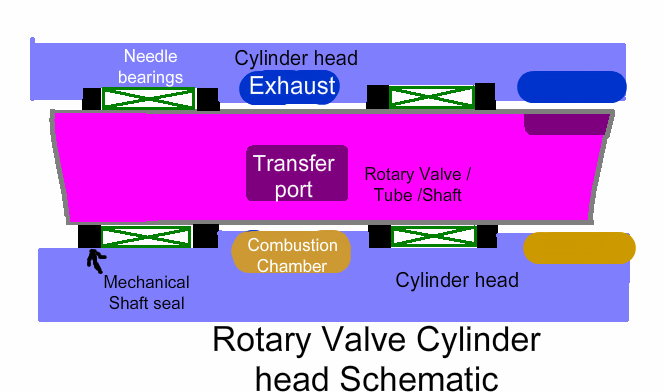

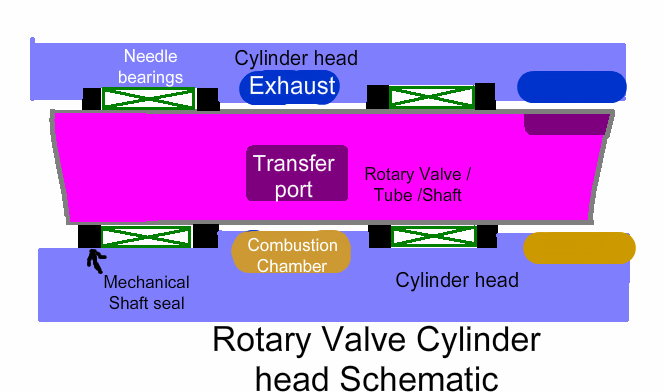

This is my original plan:

The hollow shaft/valve is in purple.

The shaft (could be Labrynth) seals are in black

Needle roller bearings are the green boxes with "X" inside.

The cylinder head itself is in light blue.

The clearances are much much smaller than it appears in the picture.

Thrust bearings are to be at the ends of the shafts.

I was not too sure about the seals. All I knew is that they had to be carbon and be capable of high rpms. Labyrinth seals in gas turbines comes to my mind. I have never seen one in real life though.

Can these provide an adequate seal around the shafts and the shoulder?

Is some spring mechanism required?

http://www.aerospace.rexnord.com/Produc ... Circum.asp

http://www.aerospace.rexnord.com/Produc ... Circum.asp

Two for each cylinder with needle bearings supporting the shafts.