Here we go, now I've given up smoking, I have to maintain the 'smokers advantage' by going outside every few hours, coming back in with the solution to an issue. It's a documented fact, measurable in the IT industry. I choose to catch out false vendor claims.

manolis wrote: ↑17 May 2017, 14:21

Hello Pinger.

You write:

“When I look I see the pressure dropping from 15psi to around 11psi (at lowest). 4psi is 0.27 bar.

The other pressure drop (on the downward stroke) is the compressed charge reducing to cylinder pressure when the transfer ports are open.”

Because the plot is for full load (wide open throttle).

With closed throttle and 1.6:1 primary compression ratio, the pressure drops near 0.5 bar (7.5psi).

You also write:

“Close off (throttle) a cylinder that has as clearance volume 1/10th of the swept volume, draw the piston down, and the pressure drop will be much larger. “

How much larger can be the drop of the pressure?

Zero is the absolute vacuum.

To the residual gas of the 4-stroke with the 10:1 compression ratio (theoretically 1/10 of the cylinder capacity, more than double in practice due to the overlap) it is added a quantity of fresh mixture.

This quantity, in atmospheric pressure, is about 1/5 of the capacity of the cylinder.

Not difficult calculations based on the data provided at

http://www.pattakon.com/pattakonIdleValve.htm :

http://www.pattakon.com/VVA_Idle/img004.png .

for the Honda - VVA-roller prototype engine of pattakon:

http://www.pattakon.com/VVA_Idle/VVA_Idle_Valves.jpg

http://www.pattakon.com/VVA_Idle/img005.png

No it's not a difficult calculation, just seems you never start with the facts, how one can innovate based on erroneous opinions and data and produce a successful outcome, you can't except by error.

Having to generate your own data because favourable data doesn't exist elsewhere so you can refer to it is referred to as fraud by the law.

Adding the residual gas (circa, 2/10 of the capacity of the cylinder) and the charge required for the engine to idle (circa, another 2/10 of the capacity of the cylinder), the cylinder is not so empty.

With 40% of the capacity of the cylinder occupied, the actual compression (or expansion) ratio is not the geometrical one (10:1) but 2.5:1, or so.

This is where variable phasing could be valuable, or pressure wave dynamics would be useful in both two or four stroke engines.

The engines you refer to achieve far better scavenging and residual exhaust gas than you claim or calculate.

It EGR is typically between 4-40% depending on load / throttle opening. This is even discussed in one of the papers you have referred to, so stop cherry picking information to suit your Explitieve.

It's well understood you want the nitrogen in the EGR to moderate combustion using ultra lean and EGR is generally accepted as ideal. It reduces peak cylinder pressure, friction, torsional issues,... Providing not just improved combustion and powertrain advantages but also design and manufacturing optimisation possibilities.

I think you should find another field to work in, clearly you do not have the rationality and clear analytical mind to achieve success accept by accident. Leave the world and it's issues to people who can more effectively engineer solutions.

Please stop pushing your other inventions on this forum, it is not for commercial use. There are other forums for that. Providing relevant accurate information is one thing but engineering falsehoods is not.

Clearly we would realise your designs would likely have issues you regularly fail to understand and address, nobody is going to waste the time give a second thought to. I tried once showing your stuff to a real powertrain engineer it was the only time I looked stupid in that discussion.

When an issue is brought to your attention your behaviour is not rational. You go off on a typical don't look their, look over here or come up with some easily debunked justification of it.

You also write:

“Question: On the design of yours you showed with the last of the transfer occurring after exhaust port closure. How so with no remaining crankcase pressure and a rising piston? I'm thinking, the flow will reverse back into the crankcase - as happens with conventional porting even.”

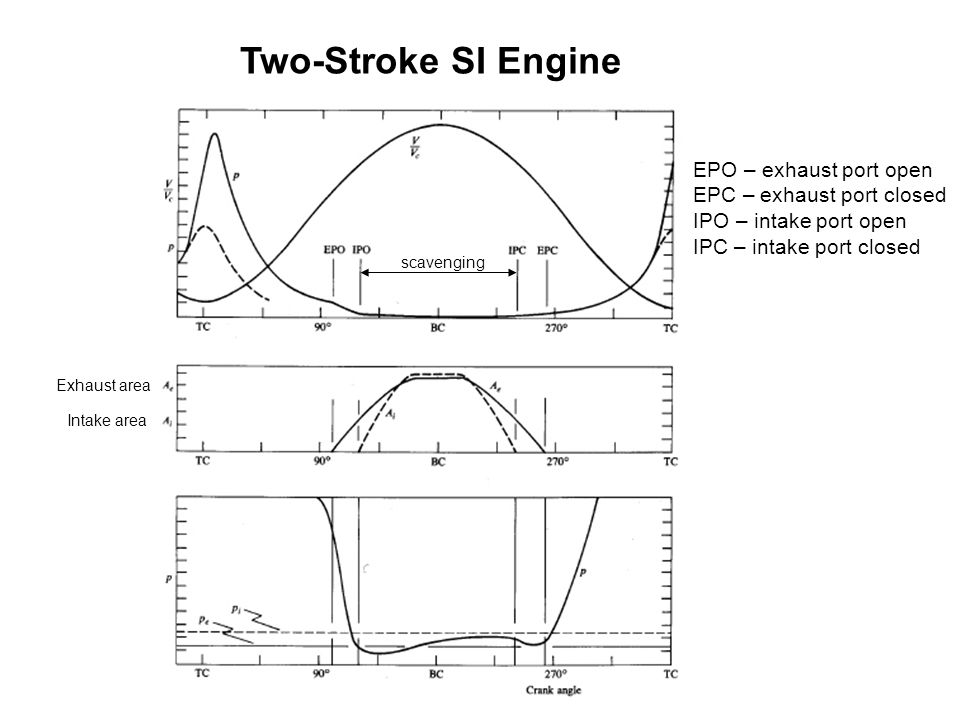

For low rpm the timing shown in the animation is aggressive.

But for high revving, wherein the inertia of the air gets in play, the timing should be even wilder.

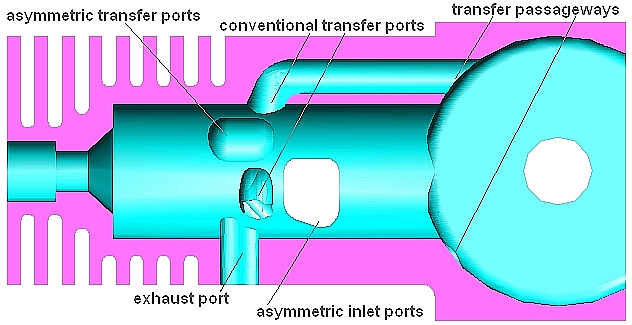

On the other hand, with the asymmetric timing, the duration of the exhaust can be substantially shorter, shifting all the ports lower on the cylinder.

Thanks

Manolis Pattakos

Identifying all the relevant issues and then Innovating based on all the facts.

This is where simulation can eliminate confirmation bias and provide a greater understanding of what is really happening, provided you have the analytical and visualisation mind and tools. If you don't have the tools you create them as needed as I have and verify them using testing and behaviour frameworks so it picks up any change that may effect some previous functionality.

This is why the old Automotive model is being replaced by a smarter model, the most successful examples are all from the information technology industry. Tesla the Neo 9 taking the lap time record at the 'ring' with electric car. Parasitic losses are more easily addressed with electric motors just put x amount of our printer solar panels on the body surface. We are now mass producing 200 metre lengths of 9% efficient 0.1 mm thick light weight solar that works well in low light, doesn't need to be as perpendicular to the light for $10 a square metre. Just have to make it fit with the visual design of the vehicle! Charging our printed multi layer Graphene super capitors used in a hybrid system for example so one has instant torque available to meet grip force at any moment, harvest excess energy or operating the IC engine at a more ideal load.

Australia had to shutdown it's Auto industry based on the old model with its high dependency on subsidies even if it was the most efficient in the world so it could build the new one. Why I have been busy leading up to our recent budget, add my mass to lobying for an advanced materials and processes industry with success. Because we thought it through and had evidence on our side understanding the forces changing the market. A high income workforce can be a major manufacturer.