ispano6 wrote: ↑25 Apr 2025, 06:38

Silent Storm wrote: ↑21 Apr 2025, 21:43

Correction : Okay, so the picture above of the central radiator is of racing bulls not the RB21. The person who tweeted it used racing bulls picture instead of Redbull.

Apologies for the error, I should have checked racing bulls gallery as well. Having said that, rest of the theory is still sound as they did move from cannons to normal, V radiator to slanted radiator and we will see in Imola if third change was made or not on RB21 that moved weight distribution of the car.

It started with having shortened the nose of the car back to the RB18/19, and they may start balancing the rest of the car to this change. Regarding the RB21 internal flow structures, they are doing something rather different from the RB19.

They haven't reverted back to the baleen whale "throat" and have stuck to the stingray mouth and halo base openings. The RB19 louvres were quite a bit smaller and farther forward. The RB21's already sit well back and lower.

https://www.raceteq.com/-/jssmedia/race ... ab0352.jpg

https://www.raceteq.com/-/jssmedia/race ... ab0274.jpg

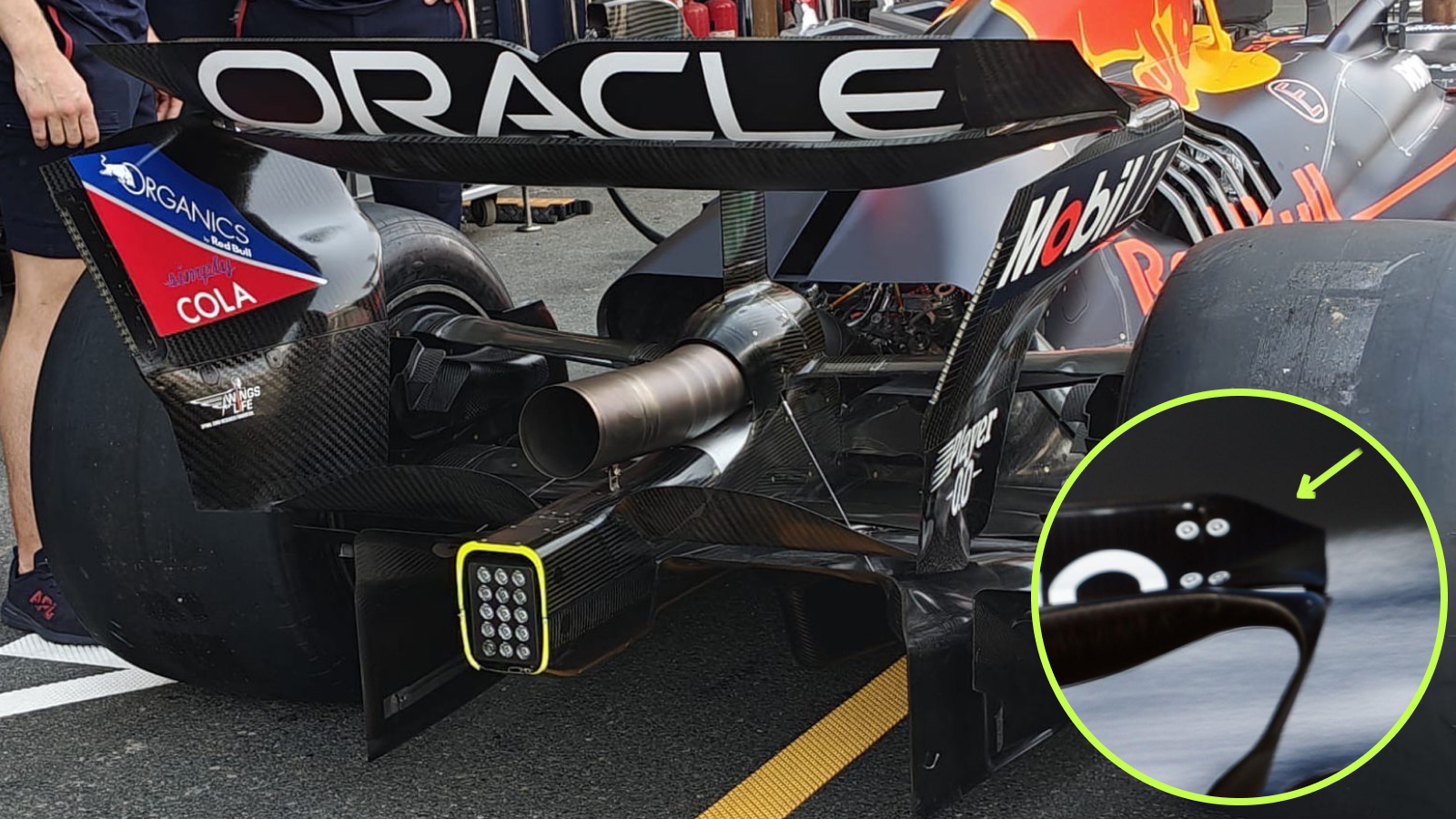

Shorter chord, less cambered beam wing, wider exit hole.

https://www.raceteq.com/-/jssmedia/race ... ab9356.jpg

From Aramco's Raceteq website:

https://www.raceteq.com/articles/2025/0 ... -explained

External inlet geometry and internal packaging are related, but not one and the same. Redbull can keep the stingray style inlet while quietly reverting internal ducts back to RB19 philosophy.

Why they don't need baleen whale throat?

The sidepod inlet controls where air enters, but the internal plenum (volume, splitter vanes, collector shape) and radiator position dictate how that air is routed. They can keep the same mouth while reshaping the inside. RB21 did move to slanted radiator of RB19 without touching the inlet.

External inlets set the boundary, but internal packaging writes the rules for radiator mass flow, heat rejection, and downstream plume behavior.

There is a reason why RB19 is brought out of retirement to run around Silverstone...

What can Redbull do in this test?

Use pressure tap arrays, thermocouple grids and mass flow sensors, and run these tests:

1) Heater mat radiator tests - Before track running, team will mount heater mats on the RB19’s radiators to bring them to realistic operating temperatures in the pit lane. Record how the pressure drop curves change when the cores are hot vs. “cold model” conditions.

2) Coolant loop profiling - Team will run a full engine cooling circuit on a dyno bench under race representative thermal loads, capturing detailed coolant side flow, pressure, and temperature maps. These are then cross referenced with data from on car validation runs to ensure correlation in real world operating conditions.

After all this it's back to factory where they will start simulator and cfd re-alignment. Basically update internal boundary conditions in their RANS/DES runs with the real pressure loss and mass flow curves. Enhance the simulator’s thermal models so that driver in loop setups now reflect the actual heat rejection and plume behavior observed on track.

By running these comprehensive cooling loop and on car validation tests, Red Bull can systematically close the gap between their digital models and the real RB21. By nailing down every nuance of internal cooling and its interaction with the external aero, Red Bull will regain the predictability they enjoyed with the RB19.

This test will also help Redbull in brake duct development. Something they said they are working on.

I learn from the mistakes of people who take my advice...