thisisatest wrote:shelly wrote:It makes sense: more than it - it is common practice. If you want something to flex on the car, you usually use fiberglass.

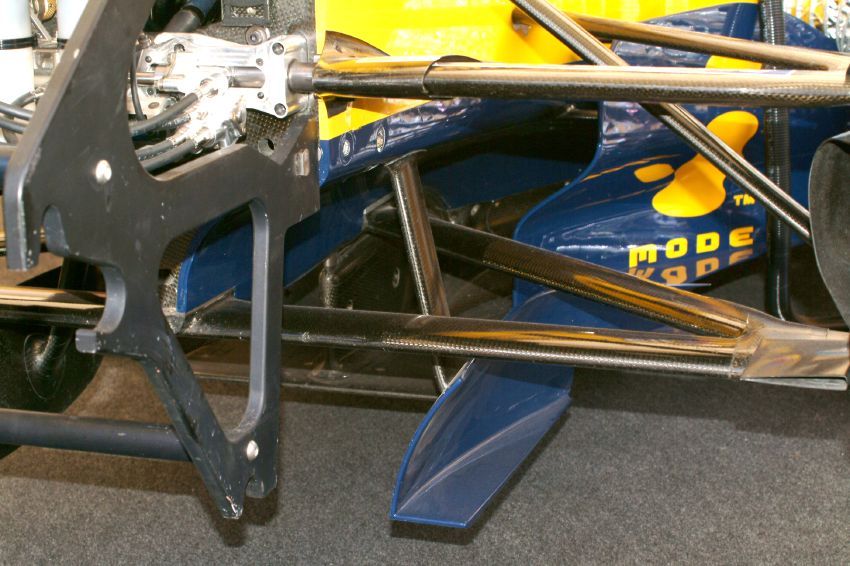

the suspension flexures are carbon. so is the "flexy-wing". it may be that in production items, it is easier (and certainly cheaper) to manufacture flexing parts of a specific stiffness with fiberglass.

Where did you get the info about flexi wings and suspension flexures being in carbon? Some years ago they were made with fiberglass - maybe the technology has evolved and now they are made in carbon. Anyway the loads in that cases are higher - for the t-tray glass would be still an option.

@flyinfrog: you cannot get more flexible than 1 layer of carbon, that's why glass is a good option.For example in the regsit is prescribed taht the rear wing spacers cannot be made in a material with modulus less than a certain threshold, specifically to ban fiberglass

@cbeck: the article did not mention glass, it is me that put it into the discussion.