Edis wrote:ringo wrote:I don't the stratified mixtures will be used under full load. If by stratified you mean extreme a:f ratios.

This will limit how lean you can go with homogeneous mixtures.

A stratified mixture is an air/fuel mixture that is limited to a part of the volume in the combustion chamber, normally around the spark plug. Around this "volume" of air/fuel mixture, there is only air. As such, the air fuel ratio in this limited volume can be for instance lambda 1 while the lambda for the cylinder as a whole can be for instance lambda 2.5.

If it could be used at full load, it could provide an efficiency gain. No unburned fuel due to air excess, no fuel wasted as cooling (cooling is provided by the excess air) and lower heat losses to the cylinders due to the insulating layer of air and lower temperatures. Of course, achieving a good stratified charge at full load and high speed is not easy, perhaps not even possible. So far, no racing engine have used it, probably not even at low loads.

@Edis

thanks for your recent posts ........ but ......

stratified charge is surely of value only at partial powers (to reduce power without the (two types of) losses due to throttling)

at full power SC is wastefully pumping, and compressing/heating excess air that is not necessary and not used for combustion

surely this outweighs all the factors as mentioned above ?

(and an afr of 1.01 lambda would give essentially complete combustion without excess pumping of air)

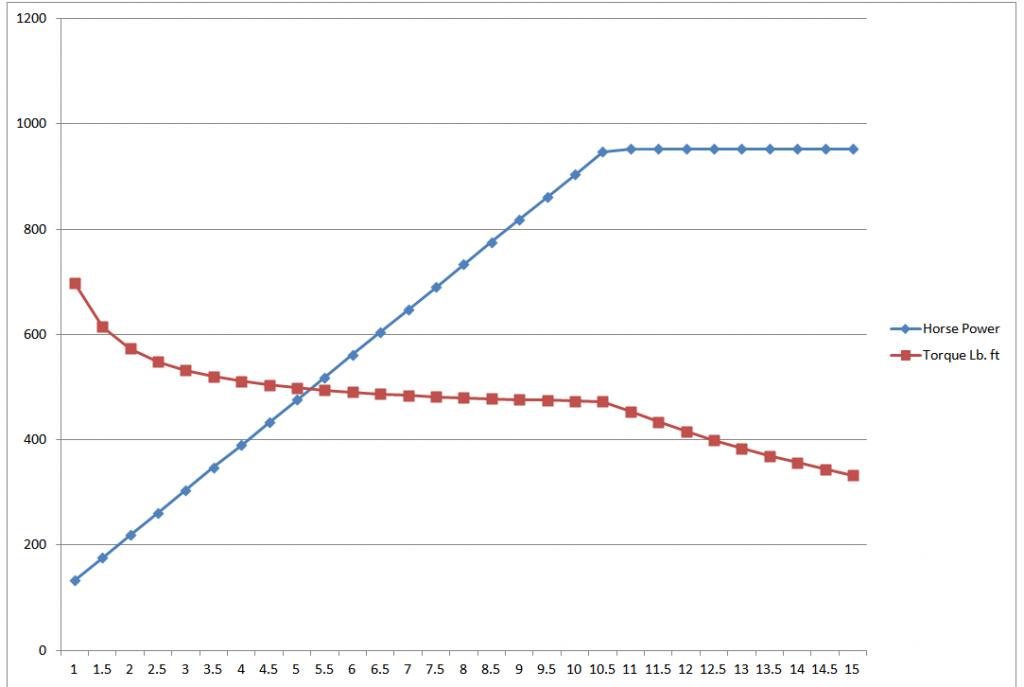

the pressing need IMO is usefully to control cylinder charging over the 16% working rpm range (10500-12200 rpm)

generator load control allows some independence of induction pressure and scavenge .... eg

we could control turbo rpm (via generator load) to reduce VE as engine rpm increases (fixed massflow matching fixed fuel rate)

(with (the right) fixed generator load, the turbo rpm wouldn't tend to increase with engine rpm above 10500 anyway ?)

we could control turbo rpm (via generator load) to maintain VE as engine rpm increases (so progressing mixture to 16% leaner)

or even increase the 'VE'/charge mass as engine rpm increases ?

(the leaning or dilution with increased engine rpm gives a detonation margin that should be used, to improve TE)

the real aim is to maintain/increase charge pressure (rather than massflow) with rpm, ie without compressing unnecessary air

so it may be better to allow dilution with exhaust gas, via exhaust valve opening later than otherwise

(ie '100% air at 10500 rpm, could be allowed to progress to '86% air/14% exhaust mix' at 12200 rpm)

this would allow more in-cylinder expansion (than otherwise)