DaveW wrote:

Apologies, Ringo, but I don't think you understand. Ignoring the undoubted fact that the spokes of a tweel can transmit a small compressive load both before & after they buckle, I think a short ponder over the fine photograph you posted might convince you that by far the majority of tweel spokes under the loading condition shown are under tension. Those under compression are buckled, & transmit very little load.

They are still under compression even when buckling. They haven't passed their yeild as yet. They will return to their original shape like any other spring under a compressive load.

Yes the spokes on top are under tension because the load is being distributed by the band of the contact surface, which is very stiff tube if you will.

But again you cannot ignore the load on the lower spokes; their deflection determine how the displacement of the band and hence how much tension is reaching the upper spokes.

The air will play a similar role in the vertical direction. It has a stiffness, no different than a pneumatic valve in an F1 car.

So, the air that is missing in the tweel is being replaced by the spokes. The sidewall is what's missing here without a replacement.

I think the tweel is very instructive in demonstrating how a pneumatic tyre actually works.

The tweel is demonstrative of how contained air works.

Some have stated that a tyre contact patch area is exactly (& necessarily) equal to the applied load divided by the internal pressure. If that is the case, then why does the belt of a tweel not collapse onto its wheel rim? It is because its shape is maintained (more or less) by tensile loads in the spokes (they don't like to increase in length, if you like). The side walls of a pneumatic tyre work in the same way - when they are stabilised by internal pressure. Having said that, the side walls of low profile tyres tend to be able to support serious loads without being pressurised - for example touring car race drivers complained at one time that they didn't know their 19 inch tyres had punctured until they disintegrated.

I don't think the total contact patch area equal to the applied load / air pressure.

The side wall takes some of the load, but the air pressure is largely responsible for pre laoding the sidewall radially.

For me, the tweel demonstrates that it is the belt that transmits load to the road surface. Internal pressure is important in a pneumatic tyre because it stabilises both the belt & the side walls that serve to maintain the shape of the belt (as do the spokes of the tweel). Loads are transmitted from the rim to the belt mainly (though not entirely) by the spokes (or section of side wall) furthest away from the road surface - as suggested by Ciro & others. I say not entirely because the side walls do, I think, transmit some load to the rim both by compression & shear. I would concede, however, that the proportion of load transmitted in that way is normally quite small.

The belt transmits the load of course, but for the tweel, the spokes would not be deflecting from a zero force. You can't ignore that spokes of the same strenght as the ones on top are buckling.

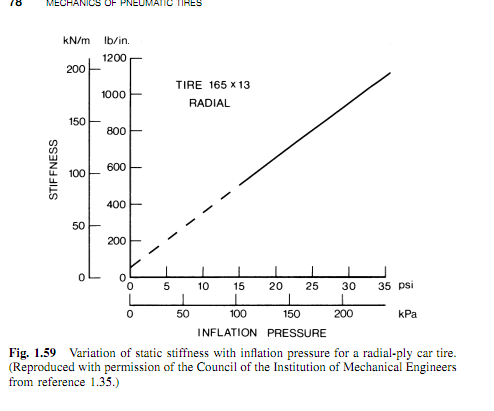

When you then go on to say the air "stabilizes" a normal tyre, it even shows that you admit that the air is contributing to the stiffness. I can't see what else stabilizes is suppose to mean.

p.s. Apologies again, Ringo, but I can't see much similarity between the skirts of a hovercraft & a pneumatic tyre. A hovercraft "sits" directly on a layer of air under pressure. It could (at least in theory) do that with or without skirts. Skirts simply make the concept more efficient by reducing leakage.

Ahhh you can't see it.

But these very same cables of the suspension bridge analogy have to be sitting on something. They cannot be sitting on the sidewall, for that would mean they would be sitting on themselves and under no loading; which is not logical.

Using the same bridge analogy, what is it that represents the towers that resist the cables?

I see it as the air pressure transmitting uniform load to it's container providing hoop stress to the walls and belt and in effect the cables which is what's supporting the upper side of the tyre.

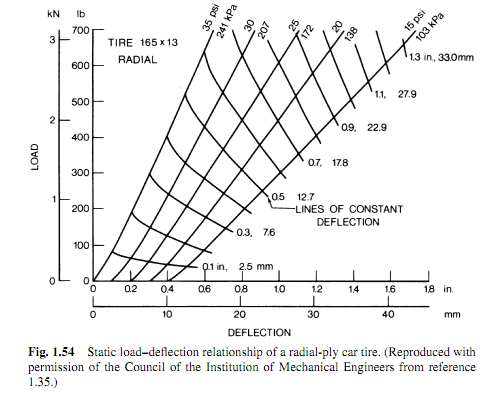

Deflating the tyre would affect it's stiffness. So a tyre's stiffness is dependent

on it's air pressure.

A run flat tyre is an example of increasing the stiffness of the tyre wall to compensate for the missing contribution of stiffness from the air.