Hello PlatinumZealot.

The Portable Flyer is actually its engines.

A couple of days ago I answered to the “same” question in another Forum, wherefrom the following quote is:

You write:

“

Wouldn't it be a *lot* easier to do proof of concept testing using off-the-shelf pieces? Use a conventional small engine, pulleys, etc.”

It depends on what you mean “proof of concept”.

If you mean to prove that you can lift a weight by two counter-rotating propellers, yes, it would.

But the Portable Flyer project is different.

And is based “entirely” on its OPRE Tilting engines, which were designed for this specific use.

Here is how the “Device Technical Report” (at https://www.pattakon...oFly/index.html ), as filed in the GoFly / BOEING contest, begins (the bold letters are from the original document):

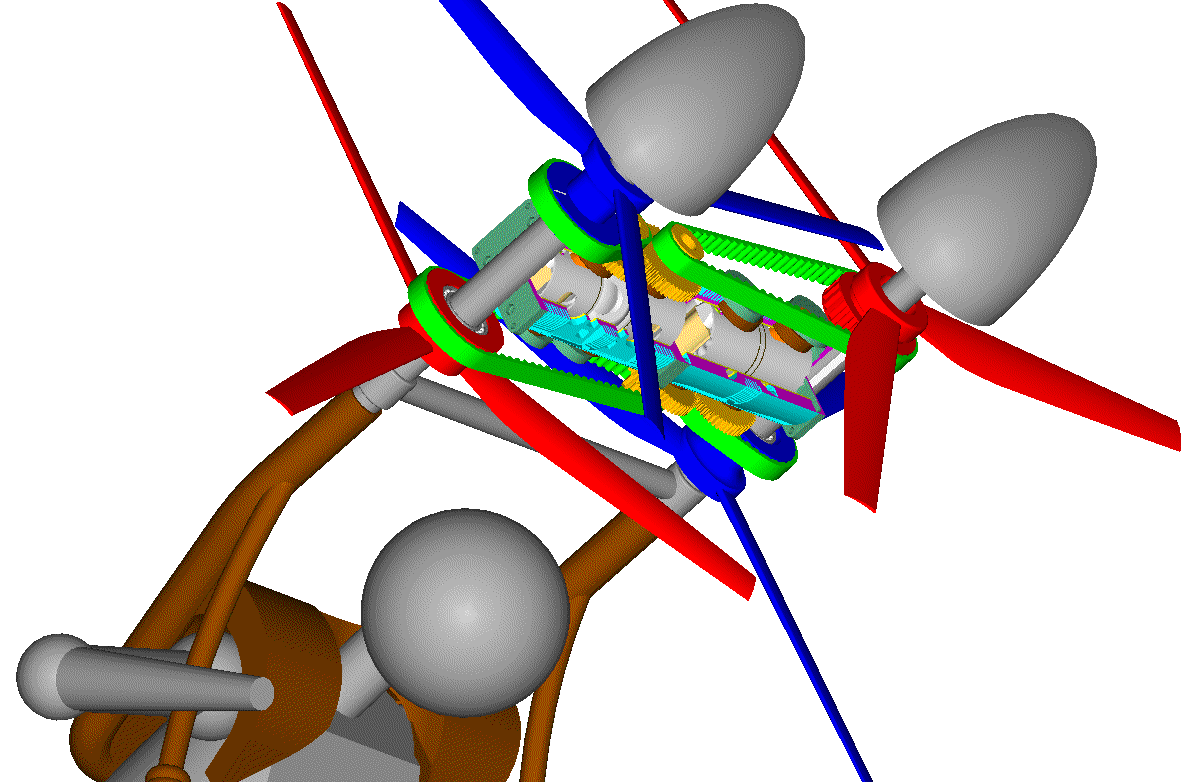

- “PORTABLE FLYER ARCHITECTURE AND BASIC DESIGN CHARACTERISTICS

The PORTABLE FLYER comprises two OPRE Tilting Engines secured to each other to form (with their casings) the personal flying device’s “backbone”.

The one engine drives two counter-rotating propellers arranged above the backbone, the other engine drives two counter-rotating propellers arranged below the backbone.

The following presentation deliberately focuses on the engines because the PORTABLE FLYER is actually its engines. The goal is the development of a new kind of “passé partout” useful transportation means uncompromised on: safety, easy use, range, speed, mileage, emissions, ownership/running cost and portability (wearable).

At the ends of the backbone they are secured two “vertical” pipes whereon the propellers are rotatably mounted. . .”

If you know a small engine and “pieces off-the-shelf” that could replace the OPRE Tilting engines of the Portable Flyer, please let me know.

But there are several requirements from such ready engines:

- You need to carry a pair of them (for safety). So they have to be lightweight (no more than 10Kg / 22lb each), because the Portable Flyer has to be wearable: pilot’s legs / feet are the only landing gearing.

They have to have high specific power (say around 5kW/Kg).

Each engine has to share equally its power on two counter-rotating synchronized crankshafts, each driving its own propeller.

Each engine has to be true vibration-free because it has to be directly secured / supported on pilot’s body.

Each engine has to have zero reaction torque: on the air the pilot has nowhere to abut on or to be supported on; the slightest unbalanced torque from the propulsion unit may prove catastrophic; any reaction torque (say at an abrupt opening or closing of the throttle, or at a misfire) may prove fatal.

Each engine has to have zero gyroscopic rigidity, otherwise the pilot will need a lot of thinking, a lot of effort and a lot of time to re-vector the thrust. Only with zero gyroscopic rigidity the control becomes easy, direct and intuitive, making the training of beginners easy, safe and fast.

So, is there in the market such engine / off-the-shelf parts?

You also write:

It's not like the novel engine design will be significantly lighter or more powerful than stuff that's readily available.

The engine that makes the Portable Flyer is more than just a “significantly lighter or more powerful engine”.

You also write:

“Whether the general concept is sound, it should obvious be pretty quickly . . . You obviously lack the resources to do it the way you want to”

and here is what you write in the "Koenigsegg" thread:

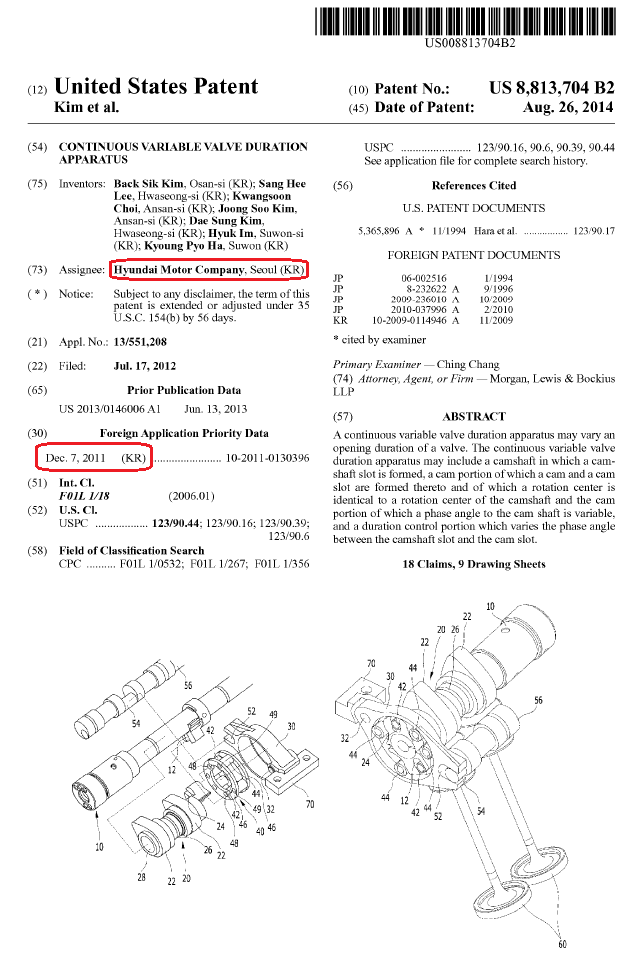

“ The Hyundai VVT system, however, is quite clever, gets most of the theoretically possible upsides, and it actually exists in numbers.”

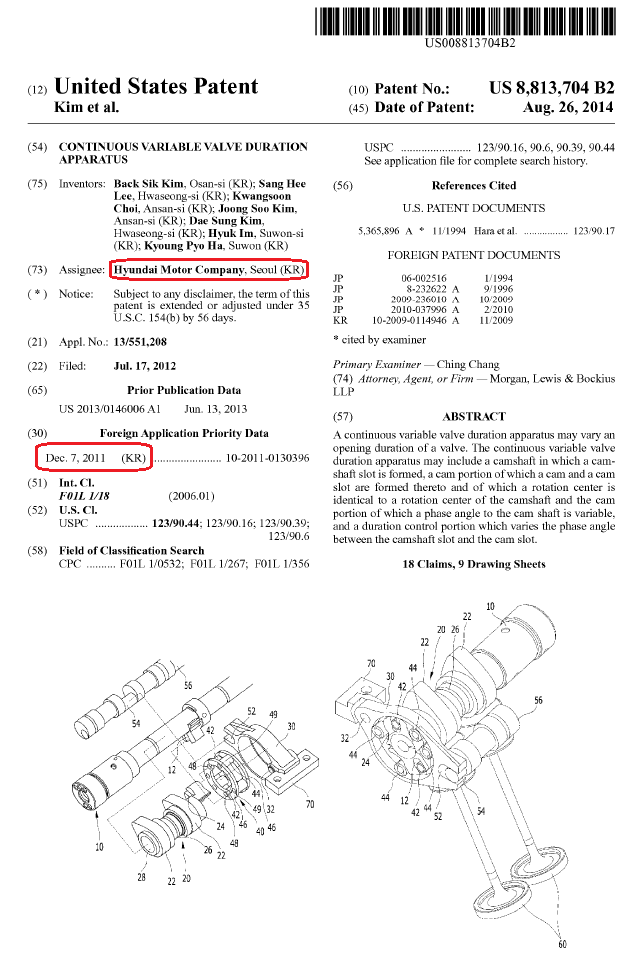

I think you mean the Hyundai CVVD (Continuously Variable Valve Duration) system.

While I obviously lack resources to proceed “quickly” with the Portable Flyer project, Hyundai does not lack resources; in Hyundai they have everything, from experience, to know-how, to machinery, to materials, to staff, to funds, to test facilities, to budget (presumably no budgetproject).

Here is the first page of Hyundai’s CVVD US-patent:

The CVVD mechanism was designed 9 years ago, and only a few months ago it was used in a mass production car.

And the CVVD of Hyundai is a simple cam-control mechanism.

The Portable Flyer is a “start from scratch” project.

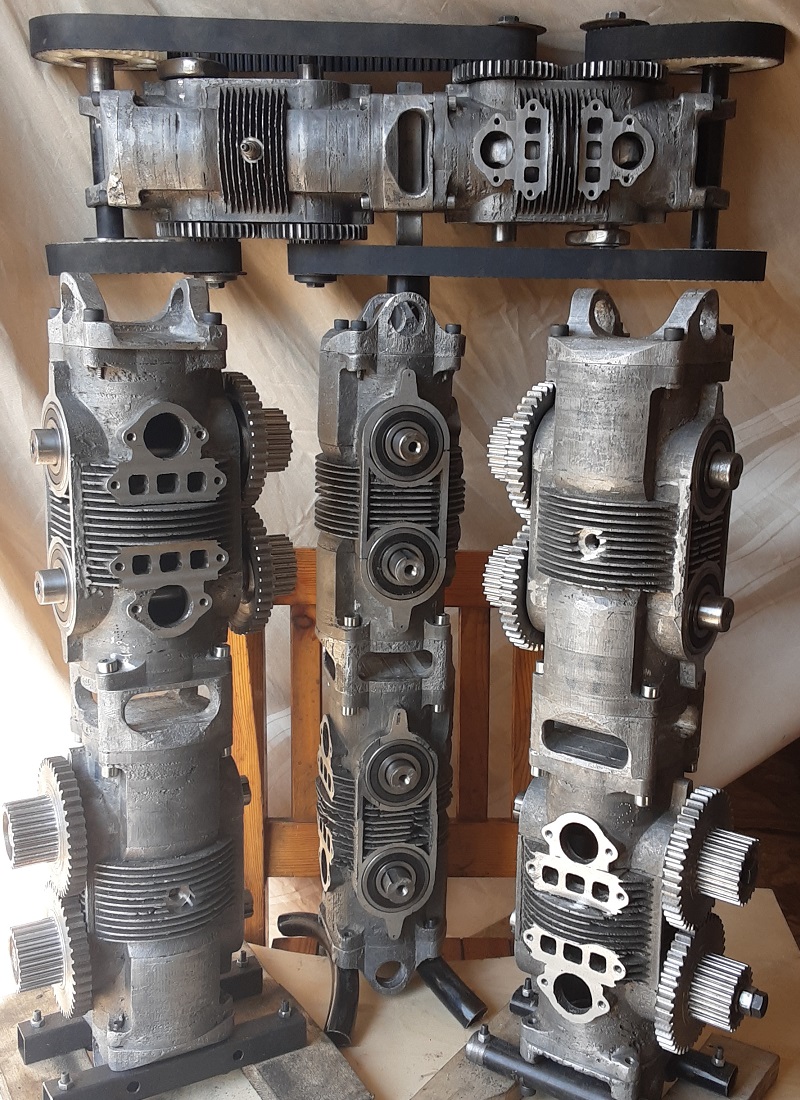

Excluding the roller bearings and the piston rings, everything else is hand made.

PS:

It will be interested to open a new thread to discuss about the “Breakthrough Engine that Answers a 133-year Challenge” (!!!) Hyundai claims.

Thanks

Manolis Pattakos