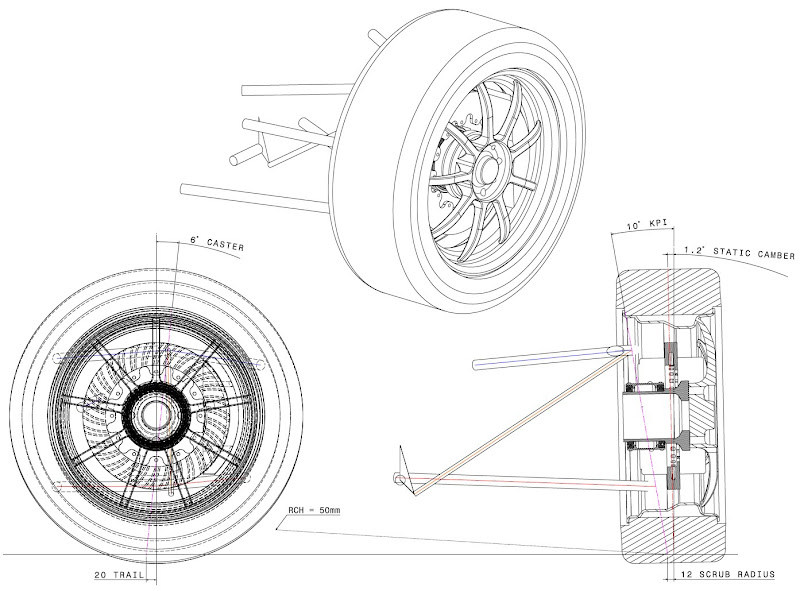

My thinking is pretty much what Greg and Tom are saying. Basically, your can get (for arguments sake) 80% of what you want without knowing the detailed behaviour of the tyres. This 80% being a suspension which is not doing anything stupid kinematically, will give predictable performance in terms bump/roll steer, camber etc and a load transfer distribution which is related to the mass distribution (like the tyre size) which will not be picking up a wheel at 0.3G or something similarly stupid.Caito wrote:How you came to the suspension pickup points? I'm guessing you have no tire data.

If you don't know push/pullrod or direct connection, how can you design the chassis if you don't know where is that force going?

The last 20% will come from a deeper understanding of the vehicle and tyres. This means building some adjustability into the design which of course adds weight, complexity etc but there is no other way if you don't have force/moment data.

On the spring actuation, regardles of all the hype here about push rod/pull rod, there is no tangible difference between the two from a suspension point of view. At least not at the conceptual level (the current pull-rod circle jerk in F1 at the moment is all based on aerodynamic advantages). Therefore, at this early stage I'm more interested in what the wheel rate is going to be but I know I can achieve it with push/pull rod or maybe even direct acting suspension. When you are designing the kinematics, the spring only gets in the way. Getting the motion ratio to behave well using the kinematics is iterative and time conusming, so you don't want to go through that every time you change your A-arm geometry. Therefore I'm leaving that puzzle, and the decision of spring actuation until after I have the A-arm geometry OK.

Regarding the packaging, there is a very simple geometry which represents the maximum packaging space of a tyre which is published as a standard of sorts by the ETRTO. If you put this in your CAD model, you will be pretty sure you won't have packaging problems.

Tim