I hope that 8 degree overlap is measured at significant lift. Even without knowing what your engine is, 8 degrees measured at zero lift is not enough overlap.pgfpro wrote:Also On my setup in which I know its not close to what a DI F1 engine is, but my engine cams are design for a high boost turbo charged application, with only 8 degrees over lap.

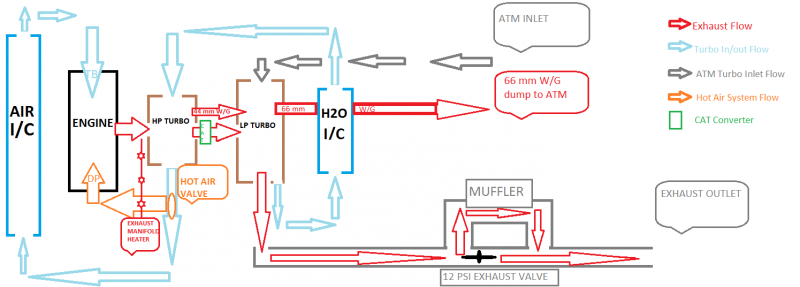

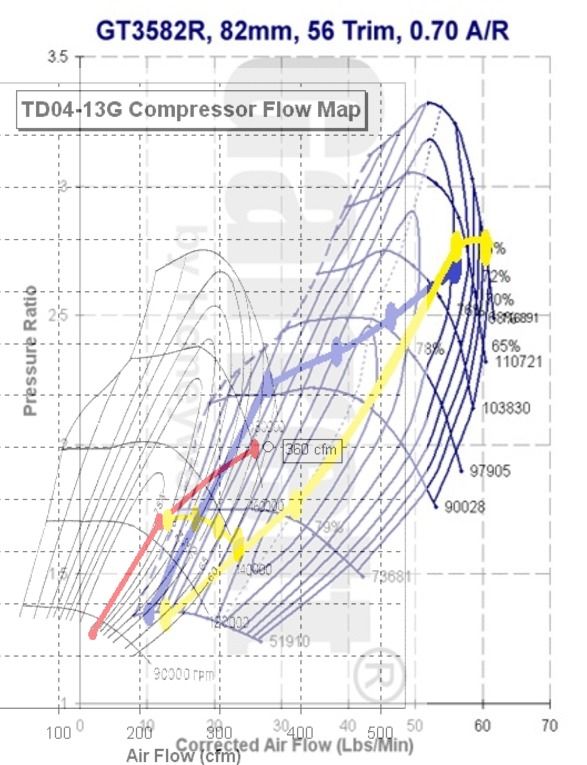

I do see knock with a poor delta p on pump premium (400whp limit), but not on race fuel VP C16 (650whp limit) but, I do see power fall off from high exhaust pressure before the high pressure turbo starts by passing the exhaust around it to the low pressure turbo. This is my question with the F1 engines loading the turbine for power to feed the MGUH I would expect them to have to keep the intake pressure equal to or more then the exhaust pressure?

Positive delta P is highly beneficial - particularly on thermally stressed engines. It is/was common practice for turbo diesel engines running in a narrow operating range to have significant overlap to utilise a positive DP to scavenge heat from the combustion chamber surfaces. Gasoline engines gain a further benefit from reduced knock but of course will waste fuel if a timed injection is not available.