- Login or Register

No account yet? Sign up

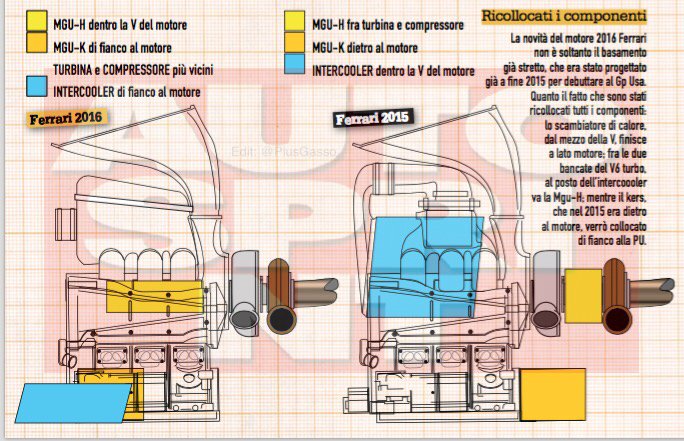

How is it air tight sealed then? Or doesn't it have to be?saviour stivala wrote: ↑06 Aug 2019, 22:11If as said the FERRARI MGU-H is in the vee it is ahead of the 90 degree ‘up’ air intake elbow so the turbo shaft drive to and from MGU-H must go out of the compressor intake and through the air intake elbow .

Reference the Renault installation. Identical layout. fwiw Ferrari were rumored to have a split turbo behind the engine 2014-2015. Not sure if true.MtthsMlw wrote: ↑06 Aug 2019, 23:30How is it air tight sealed then? Or doesn't it have to be?saviour stivala wrote: ↑06 Aug 2019, 22:11If as said the FERRARI MGU-H is in the vee it is ahead of the 90 degree ‘up’ air intake elbow so the turbo shaft drive to and from MGU-H must go out of the compressor intake and through the air intake elbow .

If it has to be air tight I think it would make sense to seal it around the MGU-H itself so that the whole shaft and front of the MGU-H is inside the 'intake elbow' rather than having it go through one side of it.

http://scuderiafans.com/ferrari-to-intr ... t9Dnd3GtroAccording to rumours, the third engine granted in the 2019 season by the FIA for the 21 races without penalty should guarantee an important leap in performance that will not only be combined with a specific fuel which has been developed by Shell.

The power unit of the Prancing Horse should bring to the track about 20 horsepower more than the previous one as a result of a greater push combustion management being able to better exploit the pistons in bi-metallic material that allow the possibility to increase the pressure in the chamber.

Do you think this would be an issue in the F1 engine? In its favour are such things as:Mudflap wrote: ↑26 Aug 2019, 22:59On steel pistons the oil tends to coke around the ring grooves - particularly on the top land. This can be so severe that the carbon build-up can actually start polishing the liner.

It is not uncommon for industrial engines to employ "scrapers" - rings which are interference fitted into the liner just above the top ring reversal, having an internal diameter slightly smaller than the bore in order to remove deposits from the top land.

It is said coking starts at around 400°C surface temperatures exposed to oil. This is not at all a high temperature for steel pistons. Al pistons do not even reach 300°C.

I'm tempted to say it wouldn't be an issue in F1 engines as their service life is about 3 orders of magnitude lower than that of an industrial engine.

Yes it was. He and both Haas' got the spec 3 engine this weekend.Brake Horse Power wrote: ↑01 Sep 2019, 13:07Giovinazzi said that the engine he blew was a new Ferrari spec?