Hello J.A.W.

You write:

“Hi Manolis, no designer who is serious about improving the high-performance S.I. 2T,

can blithely ignore the tremendous effects on power/efficiency of a tuned exhaust.”

If it has to do with conventional 2-strokes, yes.

If it has to do with heavily unconventional 2-strokes, not necessarily.

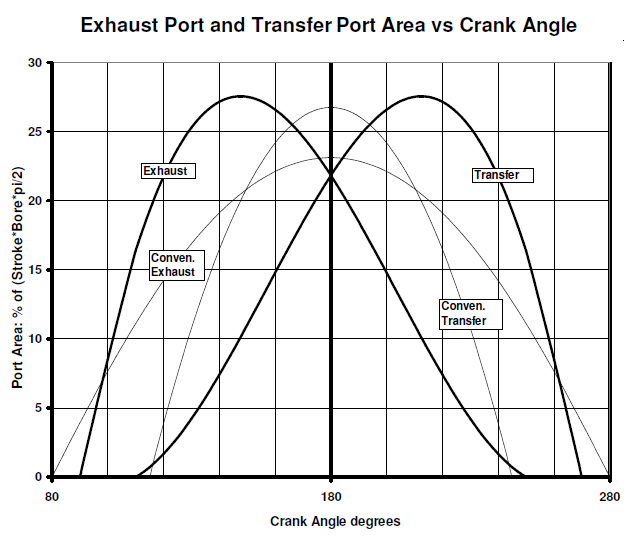

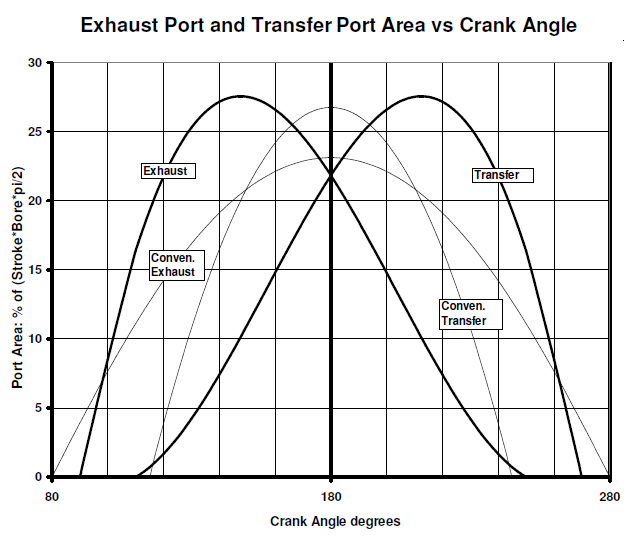

Here is the PatATE and its ports timing plot:

Obviously it is a 2-stroke.

However its port timing is “closer” to a racing 4-stroke than to a conventional 2-stroke.

Its transfer closes substantially later than the exhaust.

A tuned exhaust can’t make big difference (as it does in a conventional 2-stroke).

The geometry allows the trapping of more fresh charge: after the closing of the exhaust there is plenty of transfer port-time-area for the transfer to complete, making the breathing heavily un-conventional.

And if a compressor (or turbocharger) is used, it can make lots of power (without tuned exhaust).

Similarly, the OPRE Tilting of the Portable Flyer has a substantially unconventional breathing which focuses not in the tune exhaust, but on the tuned intake-transfer.

When the transfer ports open, the fresh charge at the transfer pipe and in the scavenge pump is well compressed augmenting the beginning of the scavenging and the sweeping of the cylinder. Later the transfer-intake path “opens” and the scavenging continues “tuned”.

A tuned exhaust doesn’t seem necessary. At least, not yet.

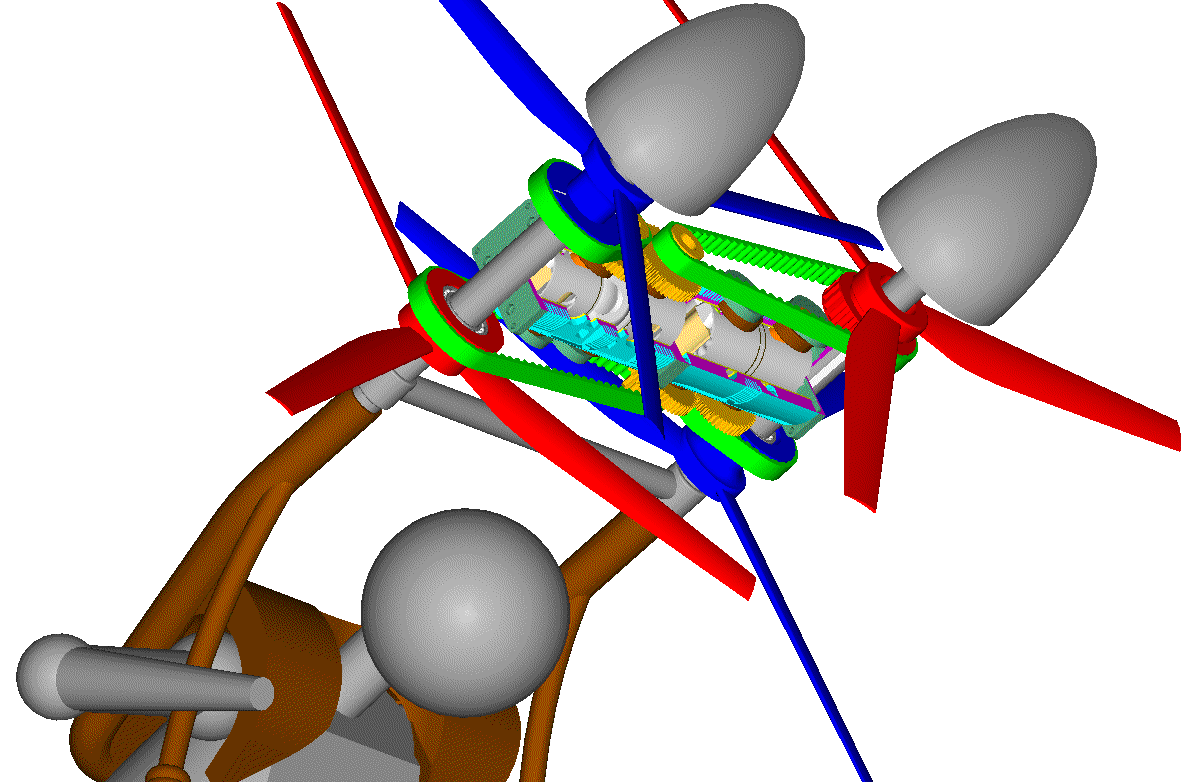

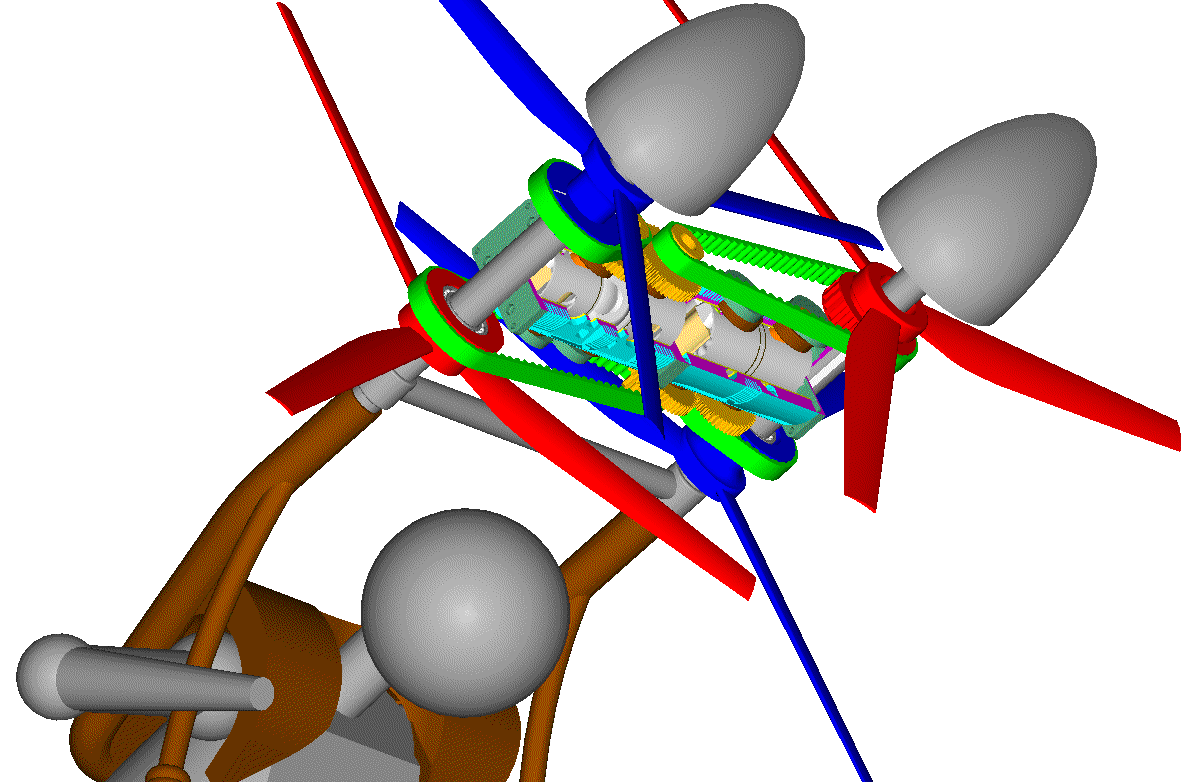

The OPRE Tilting fits well with the Portable Flyer: lightweight (for its capacity), two “direct” power output shafts (the two counter-rotating shafts), true vibration-free, can be reliable at high revs (for the same rpm, the mean piston speed is less than half than that of a typical 2-stroke), its specific lube consumption can be lower than the conventional 2-stroke, etc, etc.

For its capacity, the weight of the OPRE Tilting is small, as well as its external dimensions and the distance of its two crankshafts (opposed piston, easy and rid-of-load synchronization).

Instead of using a tuned exhaust, its capacity can be increased with lower “penalty” on the weight and cost.

I prefer to increase the capacity of the two OPRE Tilting engines of the Portable Flyer than to carry a pair of tuned exhausts above my back-shoulders.

The current design uses a pair of OPRE Tilting engines, 350cc each, i.e. 700cc in total. They will run between 7,000 and 9,500rpm (7 to 9.5m/sec mean piston speed).

In comparison, the KTM 300 EXC TPI running at “only” 8,000rpm has 19m/sec mean piston speed.

So, there is reasoning behind the choice of not using tuned exhaust.

You also write:

“Even if using non-moving mechanical parts, there are ways & means, inc' perhaps by

managing flow energies, & coiling the linear pipe-work into a space-convenient helical shape.

See below a drawing of a patent expired double-cone system:”

Here is the “double cone” complete patent document from the US-PTO:

https://www.pattakon.com/tilting/Double ... 701960.pdf

The space below the rotors of the Portable Flyer needs to be as rid-of-obstacles as possible:

Deflecting the downwash of the propellers, the pilot controls the flight.

If you could make a sketch of how you imagine the use of the "double cone" exhaust in the OPRE Tilting, it would help.

Thanks

Manolis Pattakos