I bump this excellent thread on KERS that constantly gets forgotten every two months.

There are numerous sources which I recommend to all interested readers.

- Login or Register

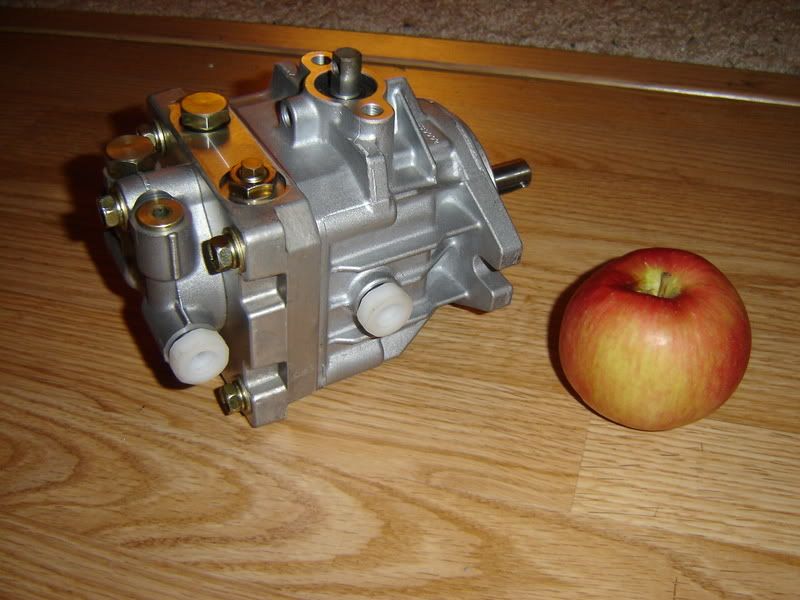

No account yet? Sign up

So quite obviously the McLaren hydraulic KERS was a motor/pump assembly (possibly a variable +/- displacement piston pump with swash angle control) that charged and discharged an hydraulic accumulator (most likely a bladder accumulator). The lack of accumulator control was probably related to a lack of suitable servo valves to control the rather sluggish swash angle plate that used to control the flow of the motor/pump.Max Mosley, AMuS, translated by WB wrote:Ich fand, es war eine faszinierende Technologie. Dann habe ich mit Charlie Whiting und einigen anderen Leuten darüber gesprochen und wir kamen zu der Erkenntnis, dass man im Bereich der Speicherung die Sicherheit nicht gewährleisten konnte. Damals haben drei Teams an solchen Systemen gearbeitet. McLaren hatte sich mit Ilmor zusammengetan und ein hydraulisches System entwickelt. Das Problem war, dass dieses System explosiv war. Es speicherte zwar nur 400 Kilojoule, was gerade einmal zum Aufkochen von 120 Gramm Wasser reicht. Aber wenn so etwas innerhalb kürzester Zeit freigesetzt wird, kann es einen heftigen Knall geben. Man hätte es über zwei oder drei Sekunden lang langsam entweichen lassen müssen, aber diese Technologie gab es damals nicht.

I thought it was a fascinating technology. I talked it over with Charlie Whiting and some other people then and we found that the safety of the storage wasn't sufficient. At the time three teams were working on such systems. McLaren had teamed up with Ilmor and had developed an hydraulic system. The problem was, this system was explosive. It stored just 400 kJ, which was just enough to boil 120 g of water. But if you release such a thing in a very short time it can produce a mighty bang. One should have let it discharge over two or three seconds but that technology wasn't available at that time.

Shrek wrote:i was wondering, when is the best time to activate the kers on the track, and do you press it on the fastest straight(like the frontstretch in Albert Park) or change the gears so that it's at redline on that straight and use it in other places

A venturi tube so small as my finger is able to propel a large heavy rotating disk gyroscope air to 10 000 RPM, and even walk through the air filter....Originally posted by Feliks

On the pictures below you can see how small the venturi nozzle is to drive the gyroscopes in the strands. My finger and applied on the next hand, illustrate the size of the venturi tube. It is almost equal to the diameter of my finger. Now, please imagine how much energy to give the fan with the same diameter of my finger...

Regards Andrew

Caito wrote:I thought another one for kers. It can be used as a starter engine. That'd mean that you would need no starter mechanism, which could make some part on the engine lighter.

I'm also thinking, since 80hp is more than enough to move an F1 car. It can be widely used behind the saftery car to save fuel(in case you need to save fuel). You just charge the last lap, when the saftery car lights go off.

The KERS motorgenerator could probably be used as a starter motor, but I don't think you save any weight by doing that since starters are external and drive the gearbox input shaft. You are also depending on that the KERS system works. The KERS motorgenerator could also replace the alternator, you only need a DC-DC converter for that. Probably worth about a kg. But again, you're depending on the KERS system functioning like it should.Caito wrote:I thought another one for kers. It can be used as a starter engine. That'd mean that you would need no starter mechanism, which could make some part on the engine lighter.

I'm also thinking, since 80hp is more than enough to move an F1 car. It can be widely used behind the saftery car to save fuel(in case you need to save fuel). You just charge the last lap, when the saftery car lights go off.

Using my ESERU/7 speed gearbox, the engine can be started at anytime without any additional weight or bulk added to the unit.The KERS motorgenerator could probably be used as a starter motor, but I don't think you save any weight by doing that since starters are external and drive the gearbox input shaft. You are also depending on that the KERS system works. The KERS motorgenerator could also replace the alternator, you only need a DC-DC converter for that. Probably worth about a kg. But again, you're depending on the KERS system functioning like it should.

Battery capacity isn't enough to drive any significant time behind the safetycar on electricity only, and I doubt there are significant advantages to be had by that. After all, all the energy have to be produced by the engine and taking the longer route to the wheels via the KERS system is probably not going to be more efficient. But KERS could be used to save fuel behind the safety car by using a smaller power boost during acceleration.

Most hydraulic pumps can also operate as motors with minor modification. If you need the pump to operate as a motor with the same direction of rotation you only need a servovalve to swap inlet with outlet.autogyro wrote:The pump drawing does not do it for me WB.

Cant see how the pistons return or how they recharge with fluid.

The system also requires an hydraulic motor.