Greetings all

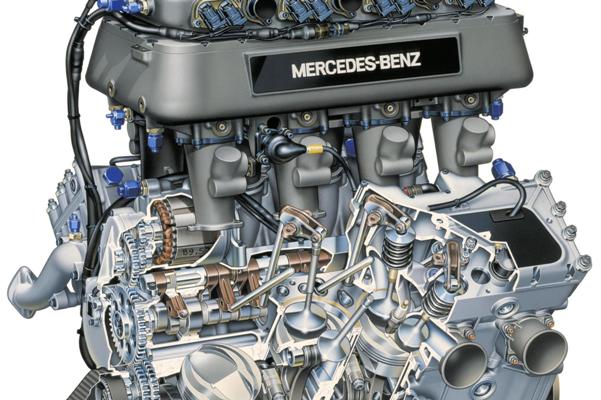

I hope I didn't miss this earlier in the thread: For OHC engines with bucket style tappets there is the option of having a curved rib on the top of the tappet. Brian G has a great examination of an F1 pneumatic valve assembly from the V10 era that has this feature. (viewtopic.php?t=15385&start=195) The BMW V10 from the M5 (Street car) also has this feature. Does this change the discussion?

On the pushrod motor front there was a system some years ago that used multiple springs distributed through the valve train to reduce the net spring force and overall component weight. Imagine a lifter with its own spring plus a pushrod with its own spring plus a rocker with it's own spring and then the valve with its own spring. Turns out that all of the mechanical bits get lighter because they aren't trying to pass the loads from the valve all the way back to the cam. Does this alter the discussion?

I really appreciate the informed discussion on this site. I almost always learn something.

Cheers,

Jon

- Login or Register

No account yet? Sign up