I have been investigating the effects of engine load, desired intake air temperature on intercooler sizing.

It's quite interesting that depending on the temperature difference you want across your intercooler, it affects at what engine speeds you will have a greater heat load on the intercooler.

I have included in my engine calculator an intercooler sizer. It uses variables like intercooler material, material thickness, tube spacing, fin spacing, desired width, air speed and cfm to come up with an intercooler length.

You also put in what core thickness you will use.

Any how here is an example:

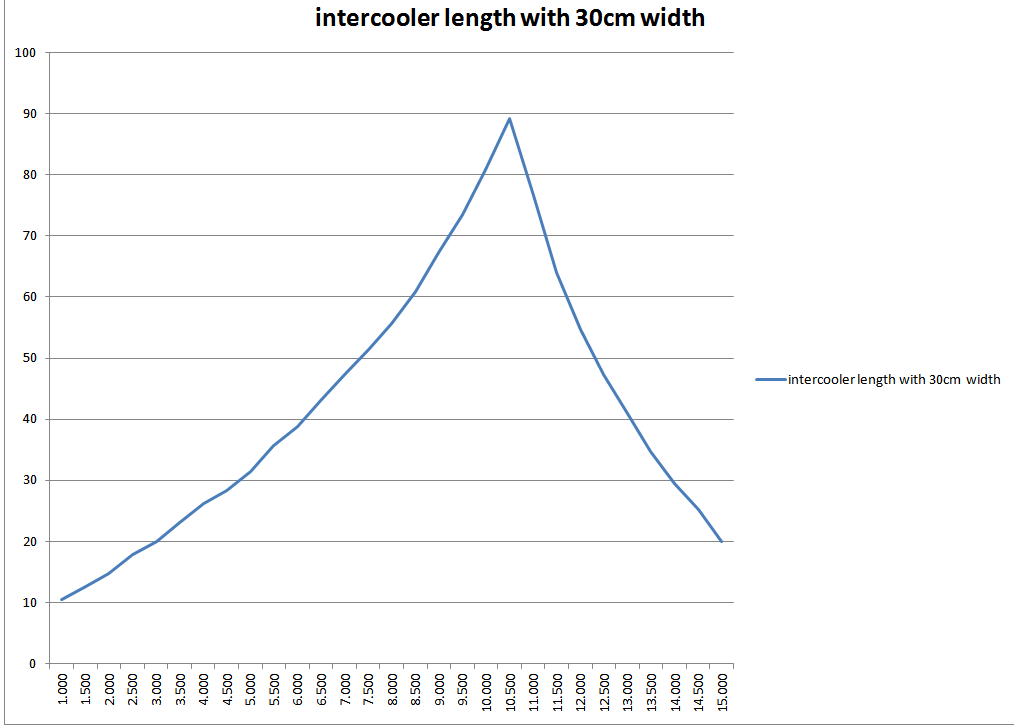

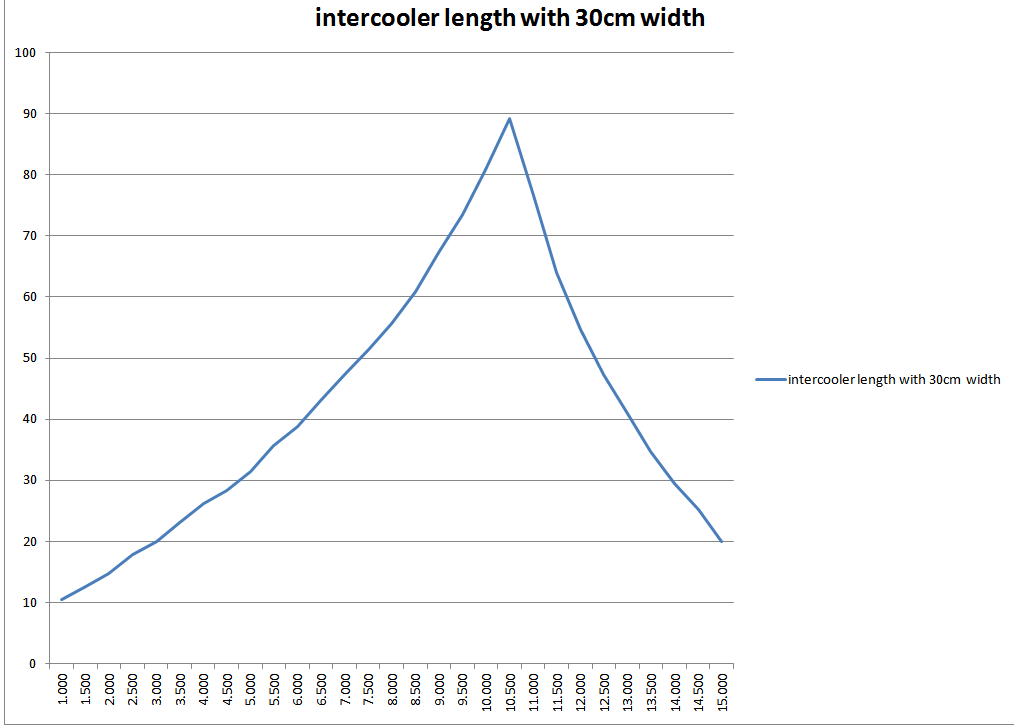

ideal lenght vs engine speed, under full load.

ambient temp: 15 degrees C

compressor outlet temp: varies

desired inlet temp: 50 degrees C

material: Aluminum

Air flow through side pod: 1200 cfm

number of tubes 50

tube height 0.005m

fin thickness 0.0005m

fin per inch 15

fin spacingm 0.001693333

tube spacing 0.01m

core thickness: 4 inches

From the above, it might make sense to go with the maximum size, as it will still cool sufficiently at less demanding times.

So this example 89cm is the height selected, this occurs at 10,500rpm logically. You can imagine 89cm x 30cm

If that's too big, i can increase core thickness or fool around with tubes and spacing etc. or simply require less of the intake temperatures.

Or i can make the interooler work at more forgiving air speeds. For the cfm above blowing through a 15 inch sidepod hole this is just about 5m/s. So with increased ground speed the size can be smaller. I can't simmulate this however. that would reqire of me to know how fast the cars are.