A few quick comments based on some of the suggestions over the last few pages:-

I found myself spending the majority of my time from round 3 onwards testing on different downforce levels to see where the best laptime was.

Yeah, I can see how this might be a little annoying....

Some ideas:-

Using just high downforce tracks as you suggest might be one idea...

Or we could organise the races so that they start off as low downforce tracks and then build up to the highest downforce track... this way from each race to the next you're simply trying to improve your downforce a bit whilst trying to maintain efficiency. ???

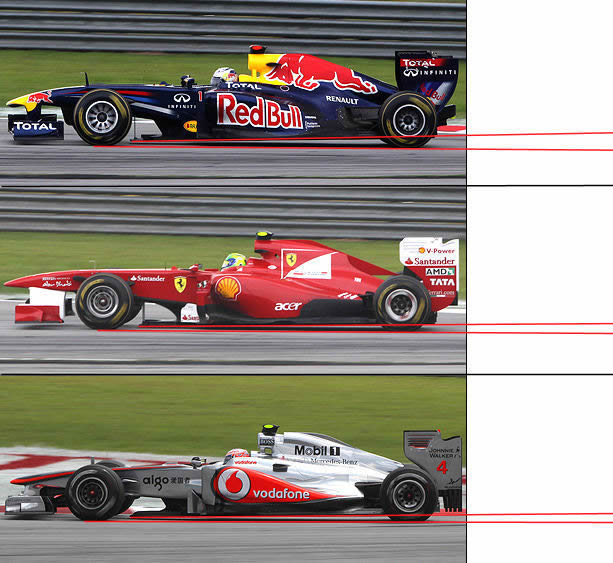

Another option is that we could generate an aero map for each car, i.e. a bit like the chart below, except the "KVRC best limit curve" gets swapped for the best limit of each team's own cars. Prior to each race the competitor declares what position on the curve he wants to play for that event; he doesn't actually have to submit a model that corresponds to that point. The aim of the competitor is then to submit cars which improve their aero-map, not to aim for a very specific set-up for each race. This also means you don't have to submit a car for a race if you don't want to: you could just use a set-up from your existing aero map.

???

If we're introducing fudge factors into the calculation.....

Personally I'm not keen on fudging the results of my lap time calculator

if we're using real tracks, since that would basically mean the validity of my program is put into question. What I could do is make up some fictitious tracks which have less reliance on low drag, i.e. which promote high downforce, or we could use actual British Hillclimb courses which are generally very tight and twisty and would promote high downforce set-ups?

It would be great to have a simplified tyre physical model next year...

Virtual Stopwatch already includes a simple tyre model as explained on my website, excerpt below:-

Competition Car Engineering.com wrote:Once the vertical loads on the tyre contact patches are arrived at using the above steps the lateral cornering forces are generated by applying the following equation:- ((A.x^2)+(B.x)+C)*((D.w^2)+(E.w)+F)*G

Where

•x is the vertical load on the tyre.

•A, B and C are unique factors for each chassis, derived from on-track data

•w is the tyre width

•D, E and F are unique factors for each tyre compound, derived from on-track data

•G is a factor relating to the tarmac surface.

It doesn't take into account temperature or wear throughout a lap, but I've found this is unnecessary for the level of accuracy required for amateur to semi-professional levels of motorsport.