Also, Wazari, while you are here...Wazari wrote:Everything on schedule. Lot's of testing and work...............

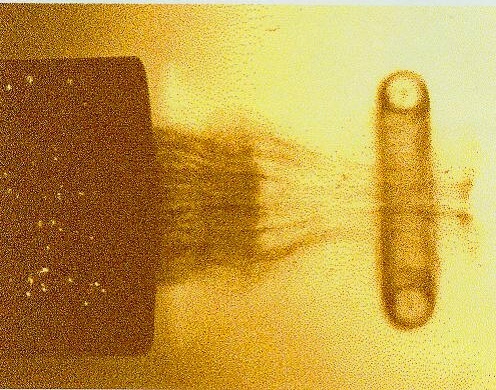

It seemed like you had some knowledge of the Mercedes "vortex exhaust" rumor. I think what it might be referring to is toroidal vortices, also known as vortex rings. Specifically, they might be inducing vortex rings within the exhaust manifold in order to better entrap heat within each exhaust pulse. Vortex rings are know for their ability to transport heat and gases across long distances, due to their self-contained, self-circulating nature. The specific type of flow I'm referencing is known as poloidal flow, although there are other types.

If a vortex ring can be induced after the exhaust port and made to traverse the length of the manifold before bursting into the turbine inlet, you might minimize heat lost to the manifold's wall. This satisfies the other piece of the rumor—that it was about maximizing heat retention.

[youtube]https://youtube.com/watch?v=Sj9irzI-Pzw[/youtube]

Initially when I heard "vortex," my mind went to a helical vortex. But helical vortices tend to be open-ended and not self circulating. So, to me, it didn't quite satisfy the heat retention quality. I thought about the concept of self-containment a little more and started visualizing different types of vortical flow. Ring vortices seem to fit the bill. I have an illustration of the idea and hope to post it soon.

What do you think? Best of luck with preparations.