Hello Tommy Cookers.

You write:

“in the conventional radial all the piston motions have the same stroke

because the slave rod pin angle (at the main pin axis, subtended from the master rod centreline) is equal to the angle between cylinder axes

according to C Fayette Taylor's 'The Internal Combustion Engine - Theory and Practice' - Vol 2 Chapter 8 'engine balance and vibration'”

A couple of pages later, Taylor continuous the balance analysis of the Radial engines with the evenly spaced hinge-pins:

“the only serious unbalance in a conventional single row radial engine is a second order force, which can be represented by a constant vector leading the crank by 180 degrees at top center of the master-rod cylinder and revolving at twice crank speed in the direction of the crank rotation.

In large radial engines this force is often balanced by fore-and-aft weights revolving about the crankshaft axis at twice engine speed.”

The arrangement in Taylor’s Book reduces the difference between the strokes of the pistons in a row of cylinders in expense of another unevenness – irregularity: the pistons may have almost equal strokes, but they arrive at their TDC at angles which differ from the theoretically correct ones.

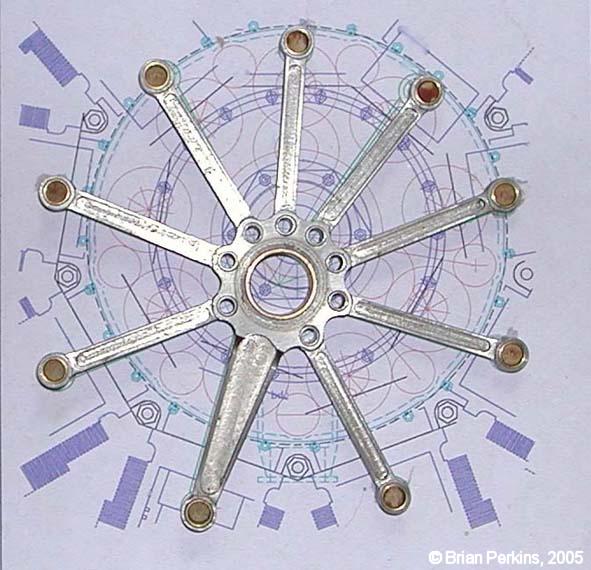

Here is the arrangement mentioned in Taylor book for a 4-cylinder Radial:

At left is the master rod (the blue cross) with the green, purple and blue hinge-pins at its big-end side. The angles of the pins are according Taylor’s book.

At right it is shown the position of the master rod per 5 crank degrees.

The green hinge-pin of the master rod, wherein the slave rod of the left-side piston is pivotally mounted, moves around the periphery of a more or less ellipse.

The stroke of the left side piston is a little longer than the stroke of the master piston, but this is not a significant problem.

A problem is the inclination of the slave connecting rod (red) when the left side piston is at its TDC.

Worse is that the TDC of the side cylinders are not spaced 90 crank degrees before and after the TDC of the master piston.

This arrangement introduces an unevenness – irregularity in the crank angles the pistons arrive at their TDC (like, say, 0, 98, 180, 262 crank degrees, instead of the correct: 0, 90, 180, 270).

In the conventional Radials with pushrods / poppet valves, a disk with several identical camlobes on its periphery and rotating several times more slowly than the crankshaft (see the animation in Wuzak’s post), actuates the poppet valves of all cylinders. When the pistons arrive at their TDC not in the correct crank angles, the common multi-cam-disk becomes another serious compromise: depending on the cylinder, the valve overlap happens either symmetrically about the piston TDC (master piston, “bottom” piston) or substantially before the specific piston TDC (left-side pistons) or substantially after the specific piston TDC (right-side pistons).

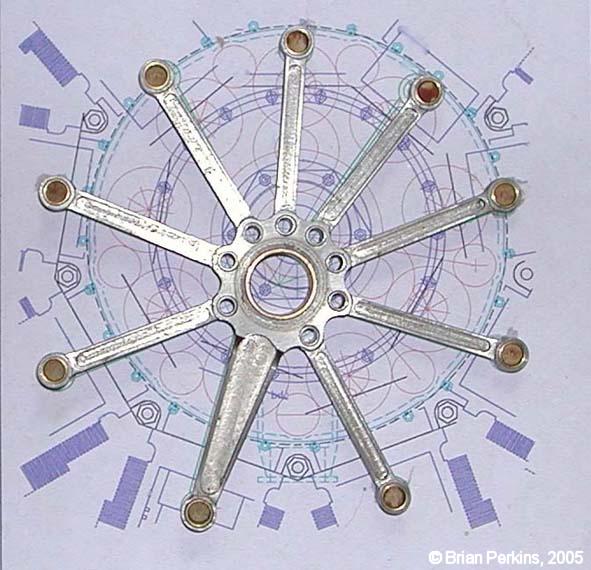

Here is a different than Taylor’s arrangement wherein the hinge-pins are disposed at different / uneven angles:

The pins on the master rod whereon the slave rods are pivotally mounted are not distributed equally. The hinge-pins towards the small end of the master rod are disposed at bigger angular distances relative to the hinge-pins away from the master-rod small end.

The side pistons have substantially longer stroke, however the pistons arrive at their TDC at even crank angles (like: 0, 90, 180 and 270 in the four-cylinder radial).

Quote from

http://www.pattakon.com/tempman/Radial_ ... _Slave.pdf

Kinematic Relations Between Master and Slave Cylinders in Radial Engines

Carl D. Sorensen

Department of Mechanical Engineering

Brigham Young University

Provo, Utah 84602

January 22, 2008

. . .

To date, I have been able to get the TDC position and stroke length errors

to be very close to zero, but with variable TDC timing.

I have also been able to get the TDC position and TDC timing to be equal,

but with variable stroke.

I have not been able to get TDC position, stroke, and TDC timing errors all

to be very close to zero simultaneously.

End of quote.

Either the arrangement in Taylor’s book (evenly spaced hinge-pins) or the most common (?) arrangement with the unevenly spaced hinge-pins (which leads to evenly spaced TDCs) are significantly problematic as regards two important issues.

The one issue is the vibration-free quality: think of am 11-cylinder Radial having a significant 2nd order rotating unbalanced inertia force loading the frame of an airplane; in comparison, a conventional six in line is fully balanced as regards inertia forces and moments.

The other issue is the unevenness – irregularity of the piston motion profiles. Look at the drawing with the path of the various hinge-pins and think how much differently the pistons move. Also see the unevenness between the leaning of the slave connecting rods: the “bottom” slave rod leaning angle is way bigger (the same for the thrust loads on the cylinder liner) than the leaning angle of the master rod and than the leaning angles of the side slave rods. Worse even, depending on the side wherein the specific cylinder is arranged, the leaning of the slave rod is way bigger before the TDC or after the TDC of the specific cylinder.

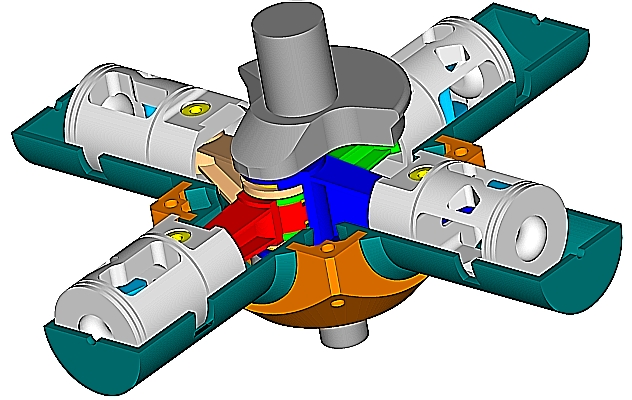

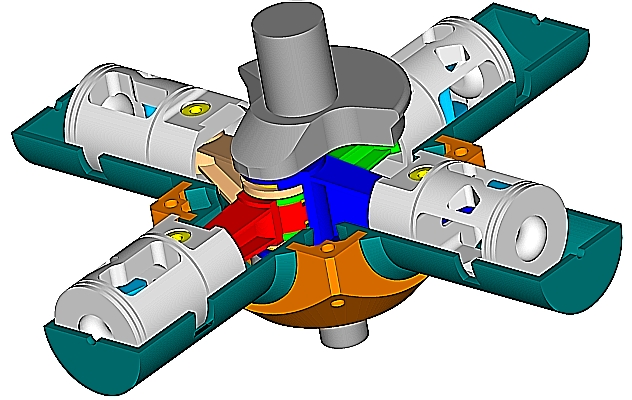

I think that after the previous analysis it is time to take another look at the PatAT Radial which with only four cylinders (and its forked connecting rods):

is a by far more symmetrical design than any conventional Radial (either with Talor’s arrangement or with the uneven spaced hinge-pins arrangement) no matter how many cylinders the conventional radial comprises.

Besides, among the characteristics of the PatAT 2-stroke Cross-Radial is also the asymmetric transfer (as asymmetric as in the famous Opposed Piston engines, but without the side-effects the asymmetric timing causes in the OP engines) and “4-stroke like” lubrication (more at

http://www.pattakon.com/pattakonPatAT.htm )

Thanks

Manolis Pattakos