You write:

"

Actually, in the view of David Vizard, the role of the exhaust in a high output 4T application - is of major importance..

He writes:

"Compared with intake, exhaust tuning is far more potent, & can operate over 10 times as wide an rpm band."

"

The role of the exhaust "in a high output 4T application" is of major importance.

but not in normal green 4-stroke engines, wherein the extended overlap is a problem, not a solution.

I think here is wherein the point is missed:

Nobody can argue that the 2-strokes can make lots of power.

However they are problematic as regards their emissions.

The focus must be on the emissions.

On anything that can lower the emissions, even at the expense of power.

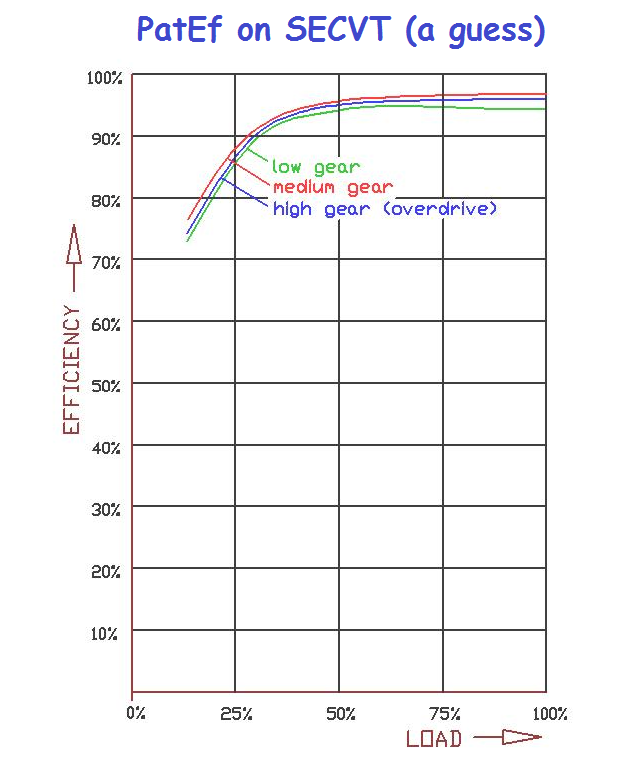

The PatATE suggests a substantially different way of operation of the 2-strokes.

And combines several unique characteristics not met in other 2-strokes (like the cold exhaust (which means, among others, substantially lower specific lube consumption), like the extreme rate of exhaust area opening, like the substantially earlier closing of the exhaust etc)

Since the lawn mower engine

is the favourite reference here, let's see how it handles the charge.

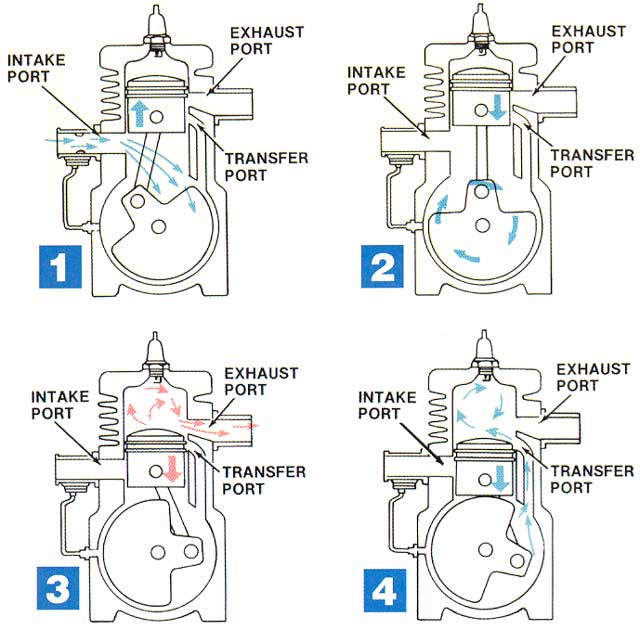

The exhaust port opens early, otherwise the crankcase, when the piston opens the transfer port, will fill with burnt gas.

After the end of the transfer, the still wide open exhaust port provides a "free way" to the fresh mixture to escape. Say as the Atkinson - Miller cycle does in the 4-strokes, but here anything that leaves the cylinder is lost and pollutes.

At the end of the exhaust, a good part of the entered air or air-fuel-mixture is not in the cylinder, and the torque drops dramatically.

And here is how things work in the PatATE:

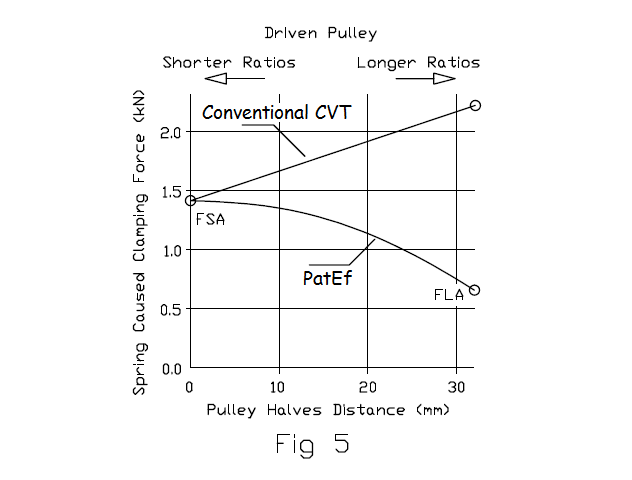

The exhaust can open later; the rate the exhaust opens is substantially higher than in a conventional allowing the faster blow-down even with substantially later exhaust opening.

From the beginning the PatATE has a gain (on thermal efficiency and on torque) due to the extended expansion allowed by the later exhaust opening.

At the end of the blow-down the transfer opens and the scavenging starts.

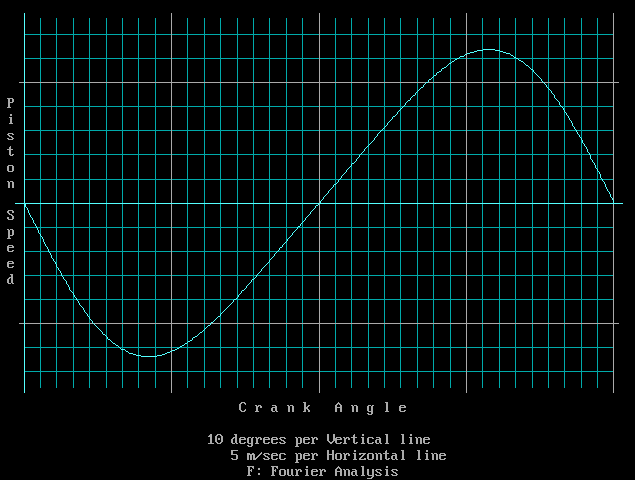

The air / air-fuel mixture from the crankcase gathers progressively speed and inertia (as happens during the overlap of the sport/racing 4-strokes, article of David Vizard), with the pressure in the crankcase dropping progressively.

The entering air-mixture expels the burnt gas out of the cylinder.

Then the exhaust closes. The exhaust can close more than 50 crank degrees earlier than in the conventional lawn mower 2-stroke engine.

During the closing of the exhaust, the rotary valve of the PatATE opens the intake port (without a reed valve to delay the begining of the intake stream).

The vacuum created in the crankcase due to the inertia of the air / mixture going from the crankcase to the cylinder, suctions new air /mixture into the crankcase through the open intake port. Like a supercharger, but for free.

When the transfer port finally closes, the quantity of air /mixture trapped into the cylinder for compression / combustion / expansion has nothing to do with a lawn mower.

According the previous analysis, the quantity of air /mixture that can be trapped into the cylinder of the 2-stroke PatATE (or, differently, the volumetric efficiency) is comparable with the quantity of air /mixture trapped in the cylinder of the sport-racing 4-strokes, like the Ducati Panigale.

And if you double the specific torque of the Panigale (because the PatATE is a 2-stroke), the expected specific torque becomes more than 30% higher than in the green KTM EXC250TPI / 2018.

Where is the mistake or the trick?

Does the PatATE design fit with lawn mower engines or with green super-2-strokes?

Thanks

Manolis Pattakos