- Login or Register

No account yet? Sign up

From the lean of peak temperatures of 1.4 lamda produce less NOx, I think Pat Symonds mentions this, could be wrong.Tommy Cookers wrote: ↑26 Apr 2022, 14:04yes 52% thermodynamic efficiency is remarkable

how does this stand ? ......

at partial power

with exhaust catalysis

at higher lambda

iirc we have natural gas ICEs running over 2 lambda ie 'heat dilution' - unlike F1 MGU-H there's no compounding

does the F1 coating so reduce heat dumped to coolant as to make such high lambda unworthwhile ?

does lean NOx catalysis need heat ?

the stoichiometric-mass heat of natural gas might be a bit higher than F1 gasoline's

does a NOx catalyst need to be upstream of the MGU-H turbine ?

etc

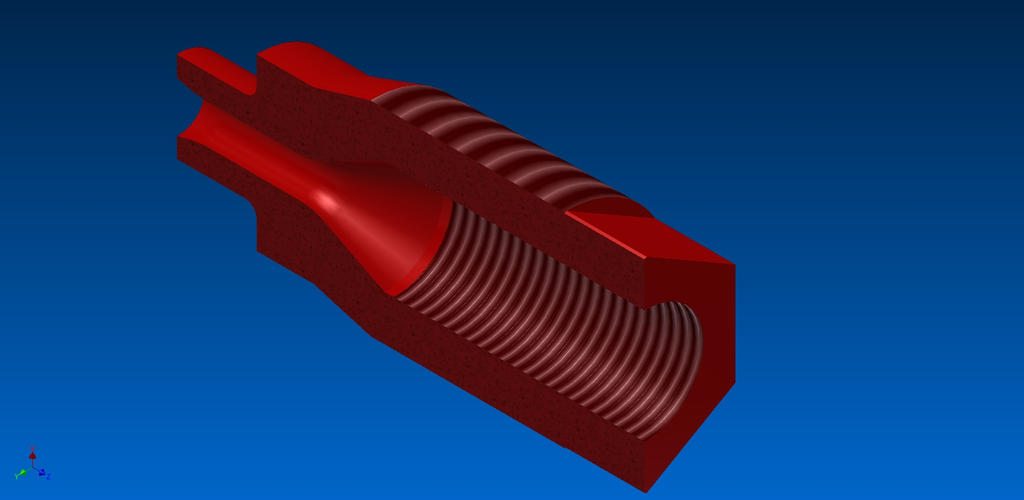

Yes, this is what some here are postulating. The CC roof won't have that much curvature, imo, more flat like a diesel. This is borne out by the camshaft spacing visible on the timing covers.

The curvature was for illustrative purposes only.

Of course the whole engine must be designed for peak TE at peak power. If the goal was peak TE only, it might be achieved at some lower load point and be even higher than 52%.Tommy Cookers wrote: ↑26 Apr 2022, 14:04yes 52% thermodynamic efficiency is remarkable

how does this stand ? ......

at partial power

with exhaust catalysis

at higher lambda

iirc we have natural gas ICEs running over 2 lambda ie 'heat dilution' - unlike F1 MGU-H there's no compounding

does the F1 coating so reduce heat dumped to coolant as to make such high lambda unworthwhile ?

does lean NOx catalysis need heat ?

the stoichiometric-mass heat of natural gas might be a bit higher than F1 gasoline's

does a NOx catalyst need to be upstream of the MGU-H turbine ?

It's too bad the corrupt gov's of the world held VW to such account for doing the same thing; not honoring the spirit of their rules, only their letter. One wonders what could have been of more R18s.gruntguru wrote: ↑26 Apr 2022, 23:21Anecdotally the current trend to downsized, highly turbocharged engines in road cars has spawned vehicles which are gross emitters at high load (rich AFR to curb knock and thermal loads). High loads are not required during emissions test drive cycles, however many of these vehicles are frequently operated at high loads to enjoy the available performance.

There is a huge difference between premixed (typical of SI) and diffusion (typical of diesel) combustion.

If everything hangs together the limiting factor is usually air supply (I know, highly arguable)vorticism wrote: ↑27 Apr 2022, 00:45Is it correct to say that the fuel injection or mixing is what limits the cycle speed of an optimized racing diesel engine? The Audi LMP1 diesels in their top form V6s redlined around 6k iirc. Would a diesel fuel ever be able to run in higher engine speeds? Maybe the method you mentioned get it some of the way there. Or is it relegated to making more power at lower engine speeds with the drawback of requiring heavier engine components.

c.120 years ago Ackroyd Stuart's CI engine using air-blast fuelling would have alleviated this situation ?

I always thought that was exactly how the single injector TJI system worked...gruntguru wrote: ↑27 Apr 2022, 00:24There is a huge difference between premixed (typical of SI) and diffusion (typical of diesel) combustion.

HCCI is a premixed combustion regime.

It might be possible to approach the F1 combustion regime in a diesel with a form of PPCI (Partially Premixed Compression Ignition) where some of the charge is pre-mixed e.g. an early spray of fuel near BDC and the remainder of the fuel is injected near TDC to initiate combustion. This technology is fairly mature in the lab. Not sure if researchers have yet achieved HCCI using this technique.

NA or boosted, the rev range, torque curves, weight considerations, etc will all play a part in component weights. Every change that might seem minor to us could be a huge design compromise at some point.johnny comelately wrote: ↑27 Apr 2022, 03:14If everything hangs together the limiting factor is usually air supply (I know, highly arguable)vorticism wrote: ↑27 Apr 2022, 00:45Is it correct to say that the fuel injection or mixing is what limits the cycle speed of an optimized racing diesel engine? The Audi LMP1 diesels in their top form V6s redlined around 6k iirc. Would a diesel fuel ever be able to run in higher engine speeds? Maybe the method you mentioned get it some of the way there. Or is it relegated to making more power at lower engine speeds with the drawback of requiring heavier engine components.

I always viewed the current F1 engine at say 11K RPM was about right for the turbo design, no need to rev higher (BMEP). But with more consideration, the relatively enormous pressures involved must call for heavier components which limit RPM. So, all in all the format works.