PlatinumZealot wrote: ↑30 May 2023, 02:33

The keener watchers among you may notice that RedBull's long floor edge wings have been adopted by other teams for the 2023 season. These floor edge wings are critical in making and keeping downforce when cornering. They are effectively side skirts and their purpose is to seal the floor while maintaining favourable air flow conditions near the floor edge at all times. They do this by staying parallel as are pressed against the road, their mounts flexing to deform the edge-wing just the right amount.

My hypothesis is the floor edge wing works critically with a hard front suspension and a soft rear as at the rear it must rest on the ground to seal approximately at the centre of pressure, but at the front of the floor the vanes must still be high enough to allow air to out-wash. The engineers must find the best combination of front and rear suspension setting to achieve this parallel seal when the car is cornering - not a trivial matter.

The springs on the floor edge seal is also critical here. The longer the floor edge wing the more conforming the seal is to the road, and the softer each spring/fence/swan neck on the edge wing can be made. The other benefit of the long edge wing is that it collects the outwash from the side pods better.

I believe the floor edge wings are probably the most important element on the floor, and they absolutely require a complex level of suspension tuning to unlock the prodigious levels of down-force they can provide. If the fact that Andrea Stella commented on them as very important elements isn't convincing enough, look how Mercedes adopted the design of the edge-wing and suspension to mimic RedBull's. We will truly see the improvement in corner exit speeds once Mercedes heads to Barcelona.

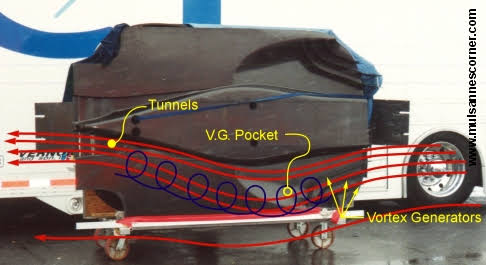

Well first, keep in mind the strakes are really vortex generators, as seen on CART / Indy Cars in the 1990s when they weren't allowed barge boards:

Lola

Reynard

Other photos:

Professor Joseph Katz outlined how they worked in a 2002 SAE paper titled "

Aerodynamic Effects of Indy Car Components

https://www.researchgate.net/publicatio ... Components

A generic, Indy-type, open-wheel, racecar model was tested in a low speed, fixed ground wind tunnel. The elevated ground plane method was selected for the road simulation since one of the objectives was to allow flow visualization under the car (and this is not possible with current rolling ground wind tunnel setups). Consequently, both the groundplane and the wind tunnel floor were transparent to facilitate the flow visualization under the vehicle. The aerodynamic loads were measured by a six-component balance, and an effort was made to quantify the partial contributions of the various vehicle components. The main trends and aerodynamic interactions measured with this setup appear to be similar to data measured in larger wind tunnels using rolling ground simulations. As expected, the two wings and the underbody vortex generators generated most of the aerodynamic downforce. The very small rear diffusers allowed by the new millennium regulations are less effective than before, and their contribution to vehicle downforce is quite small. In terms of the drag force, the main contributors are the four large wheels, the two wings and the body's downforce induced drag.

They essentially act as under floor barge boards. You can see how these VG's were placed in the previous era:

To quote Prof Katz from

Aerodynamics of Race Cars

https://www.researchgate.net/publicatio ... _race_cars

Add-ons: vortex generators, spoilers, etc. In this section we discuss simple modifications that can be added to an existing car to increase downforce. One of the

simplest add-ons is the vortex generator (VG). VGs were used for many years on

aircraft, mainly to control boundary-layer flows. The size of VGs in such applications

was on the order of the local boundary-layer thickness, and apart from influencing

boundary-layer transition, they served to delay the flow separation on a wing’s suction

side. The use of such devices in automotive racing is quite different. Here the focus is

on creating a stable and long-tip vortex, which in turn can reduce the pressure along

its trail. A simple option is to add VGs at the front of the underbody and the long

vortex trails of the VGs can induce low pressure under the vehicle. This principle is

widely used for open-wheel race cars (e.g., Indy), and a typical integration of such

VGs into the vehicle underbody is shown in Figure 13. In such an application the

VG is much taller than the local boundary-layer thickness and the objective is to

create a strong and stable vortex which, as noted, can generate suction loads along its

trail. The principle was extensively used with delta winged aircraft at high angle of

attack (Polhamus 1971), but when the wing surface was not at high angle of attack, the

interest was mostly diminished (see, for example, Buchholz & Tso 2000). A generic

study of these VGs mounted to flat plates was reported by Garcia & Katz (2003), and

the results of a similar study, but with the actual shape of the race car underbody (as in

Figure 13), was reported earlier by Katz & Garcia (2002). The combined downforce

and drag results for the two underbody shapes is presented in Figure 14. Note that in

the case of a flat plate the VGs were placed below the plate and ground clearance was

measured from the lowest point of the VG to the ground. In the Indy-type underbody case the VGs were flush with the immediately following body’s lower surface and ground clearance was measured from the vehicle’s or the VG’s lower surface. Also, for the data in Figure 14 the VGs were oriented at 20-deg yaw, and results for

additional shapes and yaw angles are presented by Katz & Garcia (2002). The downforce data in Figure 14, in general, increases as the ground clearance is reduced. The basic flat plate will have the lowest drag and no downforce. The curved Indy car underbody, but without the VGs, does generate downforce, even far from the ground, because of its effective thickness and camber. As ground proximity is reduced, downforce increases for this configuration, along with the associated drag as shown in Figure 14. When two VGs per side were added to both models, the downforce and drag increments were similar and large. Flow visualizations with these models indicate that with reduced ground clearance not only does vortex strength seem to increase but the two vortices per side untangle and get closer to the vehicle’s surface (e.g., increasing suction force). This increase in vortex strength and the reduced distance from the underbody (of the vortex) explain the increase in both lift and drag as ground clearance is reduced. At the very low ground clearance values however, a maximum in the downforce is reached due to possible breakdown effects

in the trailing vortices.

Willem Toet even confirmed they are not sealing the floors in his most recent publicly available lecture. Think about, how do you seal a floor that has a very low pressure distribution underneath of it (much lower than anything outside of the floor)? You can listen to his lecture here:

https://www.youtube.com/live/kixMMfEQ-FA?feature=share

You can see the vortices from the VG’s (“strakes”) and the vortex drawing inward from in front of the rear wheel at the 14:00 mark (CFD created by Kyle's Engineers for Willem). The whole lecture is worth watching, but Willem states that the current floors aren't sealed like you think. Also watch the slice at .25x speed at the 15:00 mark. So essentially, my understanding is the strakes create a large powerful vortex that is fed supplemental vortices from engineered leaks in the floor. You can see from Prof. Katz's work just how big of a difference they make. A lot of people are looking at them (and the floor) as if flow under the floor is laminar, when everything suggest that it isn't.

Same thing Prof. Katz is showing here:

and as seen here (

viewtopic.php?p=1115962#p1115962)

and I suspect the vorticies is probably most important at about where the pitot tubes take a reading here:

but you can also see the flow-vis flowing to the floor edge.

While I think there is merit to your theory, the fact these cars still stay on the road while running over curbs suggest to me they aren't as sensitive to ride height on the floor edge as you may suggest. Look at the Df figures from Willem's example of a 1970s design with sliding skirts and how much the Df levels change without them. My hunch is running over curbs would provide a similar momentarily loss of DF as that gap opens up. To quote Prof Katz who adds merit to that:

By the end of the 1980s this method was used in many forms of racing,

resulting in downforce values exceeding the weight of the vehicle (Wright 1983).

However, the sliding seals at the vehicle sides were not trouble free. Irregularities

in the road surface occasionally resulted in seal failure and the immediate loss of

downforce with catastrophic consequences. The effect of increasing the gap between

the ground and the seal on the downforce is shown in Figure 10 (from Wright 1983),

and a 20-millimeter (mm) gap could result in the loss of 50% downforce. This led to

the banning of all sliding seals by 1983, and in most forms of racing the only part of

the vehicle allowed to be in contact with the ground are the tires.

While I believe the floor edge is very significant to performance, and limiting inward flow where you don't want it is crucial, I don't believe it's the "silver bullet" you're hoping it is, and if anything, they do not want the floor to seal entirely (see Kyle’s video on the RB19).

However, this does suggest it is something RB is working on:

(assuming the cornering load is the same between shots)

I think all this shows that these are both drawn incorrectly though:

and the vortex is like it is in the Willem video as modeled by Kyle, and runs down the tunnel and is fed by other vortices, which Prof. Katz also states. Latios's CFD shows the same thing:

viewtopic.php?t=30734

but you can also see the flow-vis flowing to the floor edge.

but you can also see the flow-vis flowing to the floor edge.