It seems that with piston speed/acceleration the main problem (and ofcourse the FIA rpm limit) why haven't F1 considered engines other than the usual poppet valve?

Don't forget the Bishop Valve engine. Clickyn smikle wrote:There is already a thread on this somewhere.

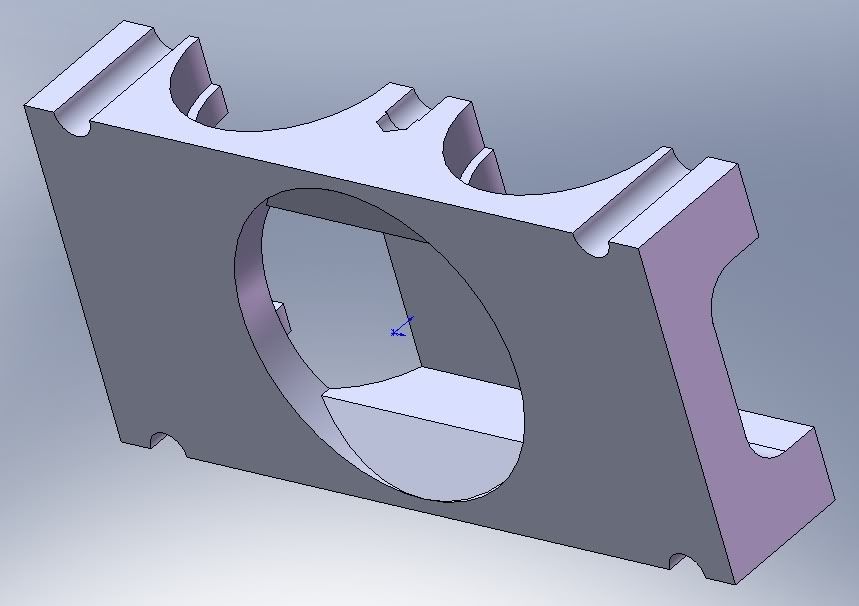

But yeah that coates engine design is the best of the rotary valve designs.

axle wrote:If we are going to revolutionize road cars then this isn't the technology to champion.

Instead F1 engines should look at variable compression and cam-less electromagnetic valve systems (the ones that can open a valve any distance for any time independently from the rest of the valvetrain/engine)...as these are of real interest to the OEM world.

No, I'm not wrong. I know people in OEM Powertrain development. They have gotten poppet valve systems far more advanced than can be achieved with rotory valves. And it's a system that is cam-less. Electromagnetic is not servo control.gcdugas wrote:No, I think you are wrong. It is still a poppet valve and it still involves all the usual losses and inefficiencies associated with accelerating reciprocating masses. A rotary valve involves no energy losses from accelerating and slowing mass. Plus any electro-servo arrangement involves lots of bent metal if there is a failure. This is the same reason pneumatic valves will never see the light of OEM day.

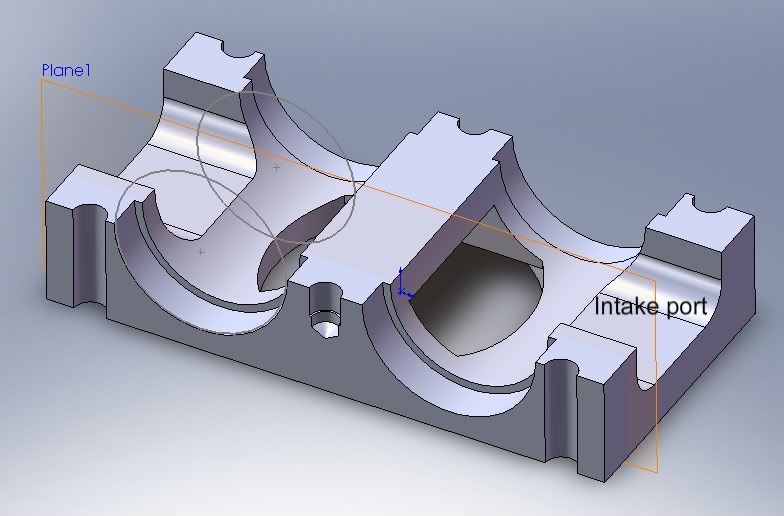

I think you will find that the limitation of both poppet valves and rotary valves is the port area possible.axle wrote:No, I'm not wrong. I know people in OEM Powertrain development. They have gotten poppet valve systems far more advanced than can be achieved with rotory valves. And it's a system that is cam-less. Electromagnetic is not servo control.gcdugas wrote:No, I think you are wrong. It is still a poppet valve and it still involves all the usual losses and inefficiencies associated with accelerating reciprocating masses. A rotary valve involves no energy losses from accelerating and slowing mass. Plus any electro-servo arrangement involves lots of bent metal if there is a failure. This is the same reason pneumatic valves will never see the light of OEM day.

Um, at what cost?axle wrote:F1 engines should look at variable compression and cam-less electromagnetic valve systems (the ones that can open a valve any distance for any time independently from the rest of the valvetrain/engine)

These are of interest to OEM research, which is a world away from the OEM world.axle wrote:as these are of real interest to the OEM world.

The exhaust valve is very hot so that means that if the exhaust and intake valve is one and the same then you have a hot intake valve.gcdugas wrote:The intake and exhaust gain nothing from being independent.