riff_raff wrote:n smikle,

What is probably more important than the static camber value at set-up, is the camber gain during suspension travel. The relative positions and lengths of the upper and lower a-arms and pivots mostly determines the camber gain/loss rates during suspension travel.

Of course, the tire sidewalls absorb more suspension travel than the actual suspension itself. I don't know the actual spring rates of a modern F1 tire carcass, but several years ago the spring rate I heard quoted for a radial F1 race tire was about 2500 lbs/inch.

Hope that helps.

Terry

In my calculations, I have the camber gain relative to the chassis; I can dial in a rotation for each lower A arm and the camber relative to the chassis comes out. I am Ok with this part. This is just for a floating chassis though. Then now I put on tyres and lower the car onto the road mathematically. This is so I can get the camber of the wheels relative to the road itself.

To do this i wanted to get the height from the centre of the wheel to the road.

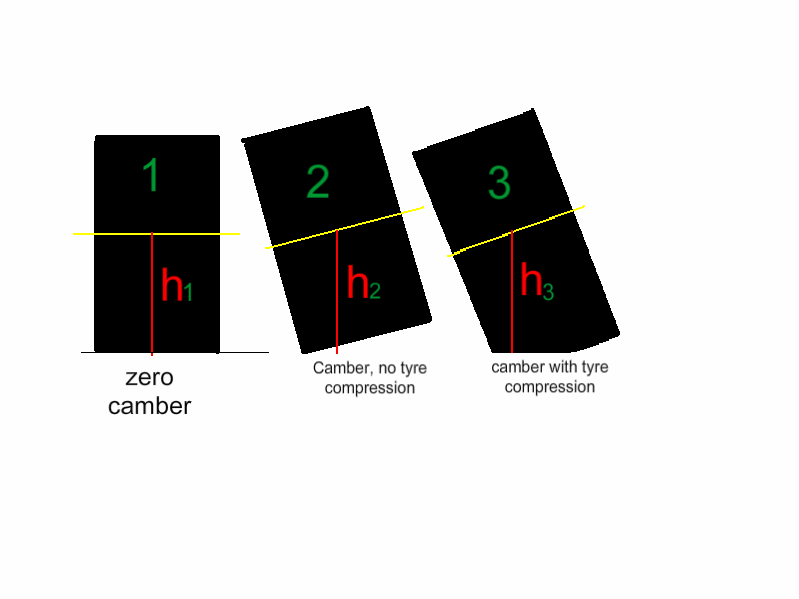

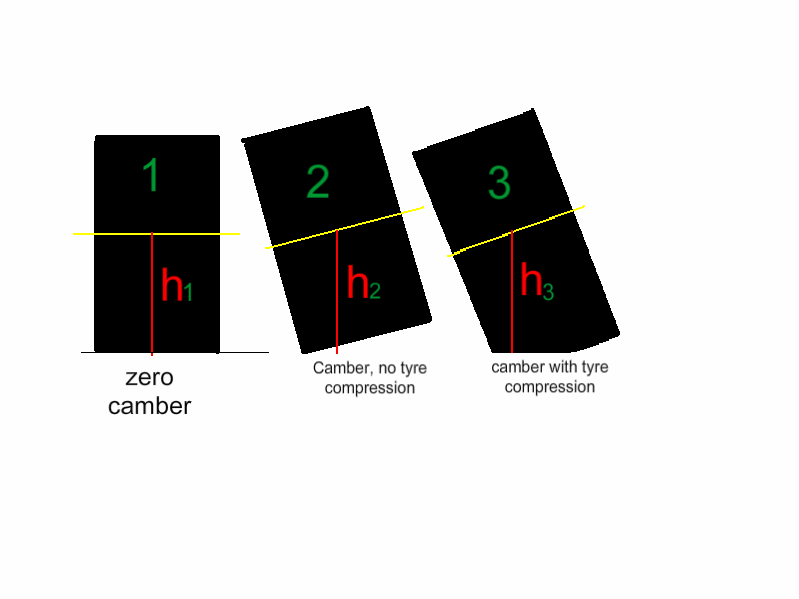

Since tyres are not shaped like a sphere, I have it that the height from the road to the centre of the wheel changes when the tyre is rocked left or right depending on the shape of the tyre cross section. (like rocking an egg). Still, I have second thoughts about this because of the compressibility of the tyres.

Since the squashing of the tyres stops the tyre from going on its edge I don't know how the final tyre height is affected.

Example here to see what I am trying to say:

How would I use the tyre spring rate(s) to find h3?

I have a feeling it has something to do with the lateral stiffness of the tyres (which I have no clue about)

Or some centre of bouyancy/pressure thingy.. i have no clue about those areas either if that is the case. Is it even necessary?

Reminds me of squashing a balloon