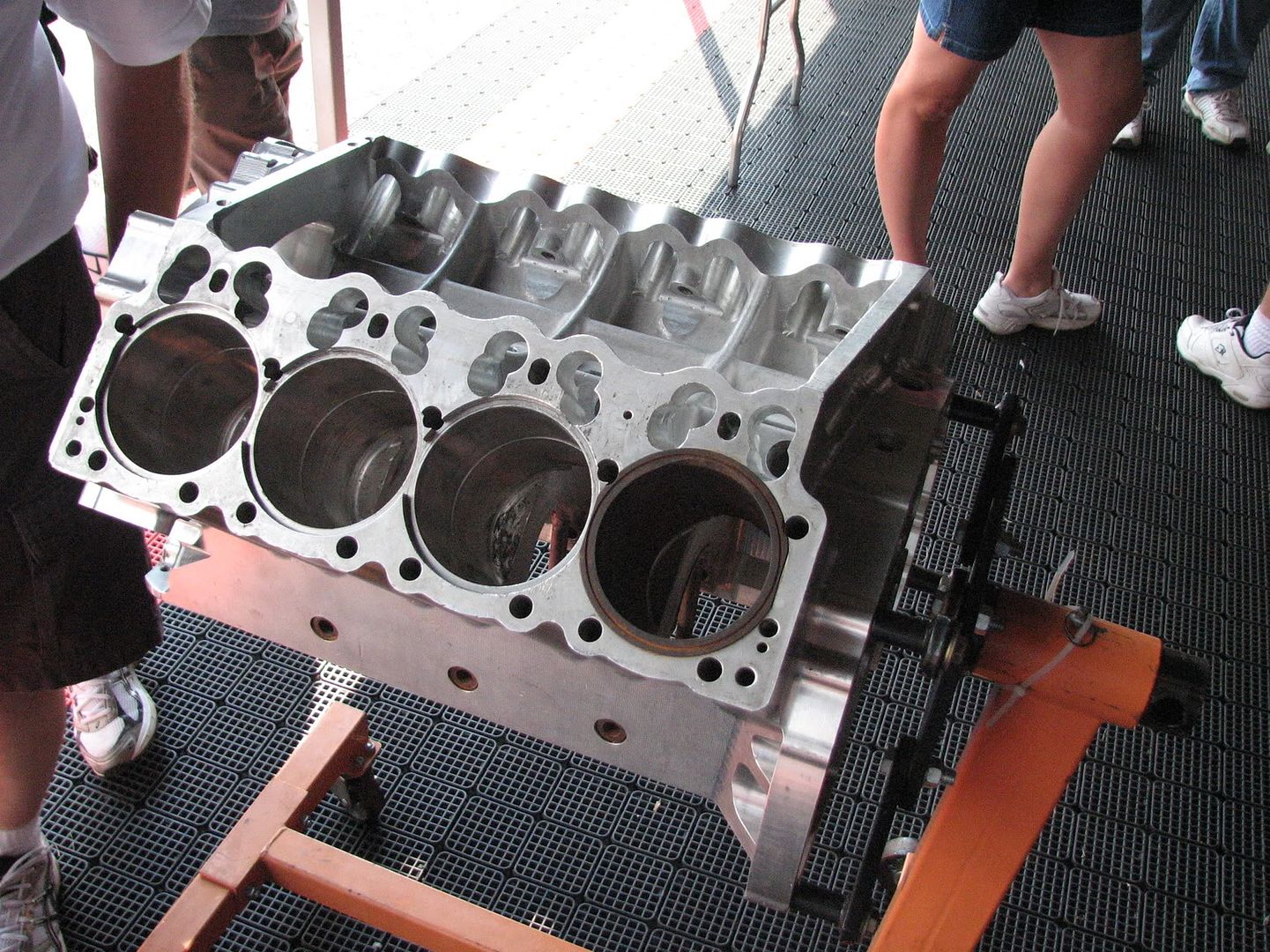

On Belatti's pics of the Cosworth you can see the closed deck, Between the two cylinders, at valve height you can see the material that makes up the cylinder wall joins at the top, just under the cylinder head. If this was an pen deck engine that gap would continue all the way up to the top of the casting meaning you could see into the cooling galleries when looking at the engine from the top with the head removed.Conceptual wrote:You know, I can see where the open deck could be better for cooling, and have a re-usable cast, but I cannot see what else it would be better at... Except for maybe some weight savings?

Wall thickness of the cylinder is easier to control and with coolant passages it is easier to kept a consistent, free flowing system, in some cases you miht end up with thicker cylinder wall for the same size engine block, which is good, but all it does is help to minimize the loss in structural strength. It's a 100% cost based decision for mass market use. If you were producing a bona fide race engine it would be closed deck as sho0wn in some of the pictures here

About the head gasket...After changing a few in my youth on various cars that I had owned, I always wondered why there even WAS a gasket there to blow in the first place... I always thought that machining a 1mm trapezoidal rib onto the head, and a matching trapezoidal groove on the block at 1.25mm would give great sealing that COULDN't blow out... An with the added .25mm (or so), you could even add some Loctite to it.I'm sure that it would need to be added at the design stage, and not able to be added to an existing casting, but when you are changing your 4th head gasket on as many cars within a 2 year stretch, you will come up with ANY reason that it is the designers fault for your troubles...

Of course their have been engines with NO head gasket, sealing ring, or anything. You plunge a blind hole almost all the way through a block of metal (the engine block/cylinder) Put holes in the blind end for spark plug and valves, and everything is fitted from the open end. An absolubte nightmare to manufacture and build, but you will never need to change a head gasket. Just pray you never need to re-lap the valve seats

I thought someone might mention this, hope you don't mind me telling everyone belatti? On top level drag engines they fill all the cooling galleries with liquid metal to give maximum strength. Water cooling can be completly eliminated for such a short run, absolubte strength is the only priority. Looking at the top of one of these engines, the only holes are for the pistons and the head bolts.Belatti wrote:What I have not ever seen are the decks of a Top Fuel engine

And I'll throw in the only thing more that I know (haha). On some open deck engines aftermarket tuning companies offer 'spectacle plates'. named as such because on a 2 cylinder engine (for example) they would resemble the frame of a pair of round spectacles (obviously without the arms - duh). These can be inserted in the cooling gallery from above to strengthen the cylinders near the top.

Because the casting will not necasarily have any location surfaces, some machining of the block may be neccasary. This can be quite an expensive process although very little material is removed.