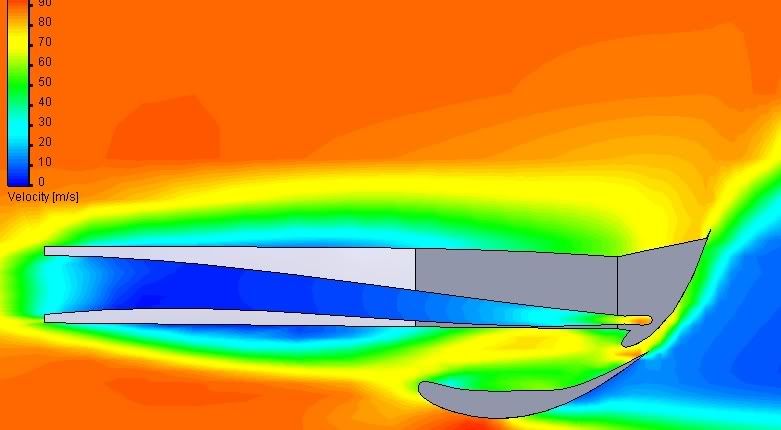

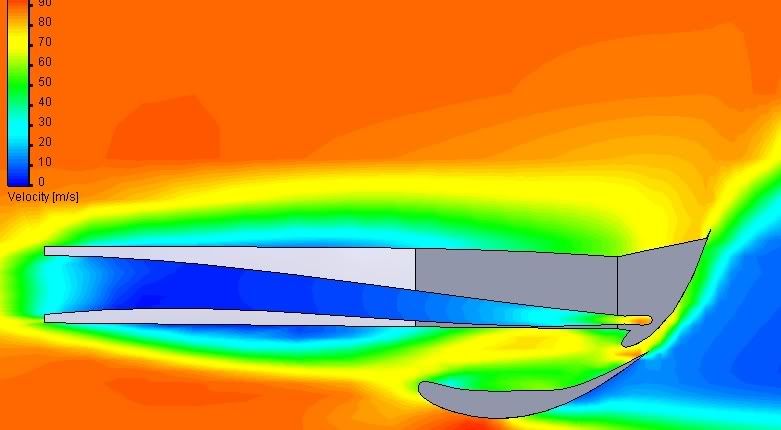

What i have found out is that the velocity coming through the slot is not multiples of the free stream. I also found that the inlet has a ram effect.

The reason the velocity is low is because of some choking, friction and end and bend losses.

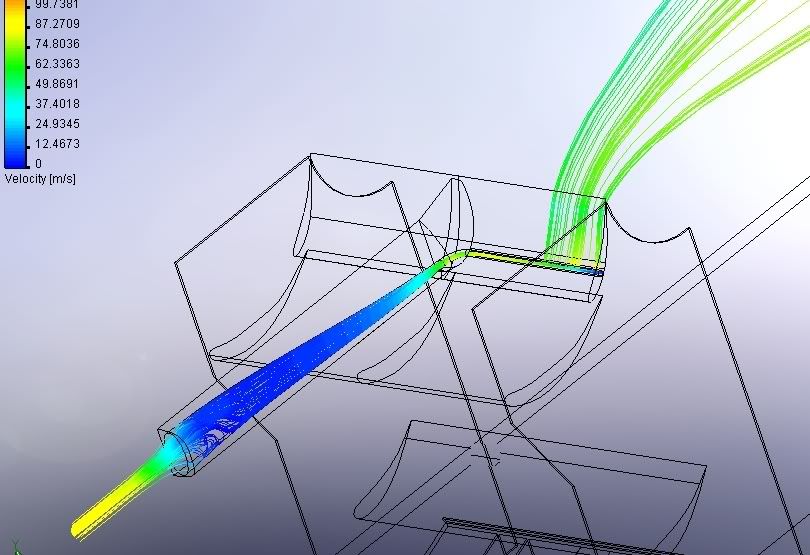

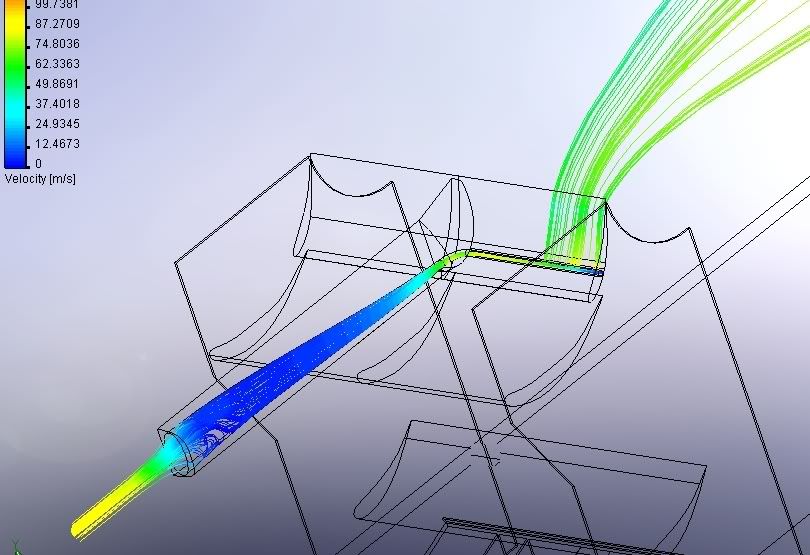

This is a fin i added, it's not what exactly on the Mp4, but i think it may have a nozzle in the fin like this.

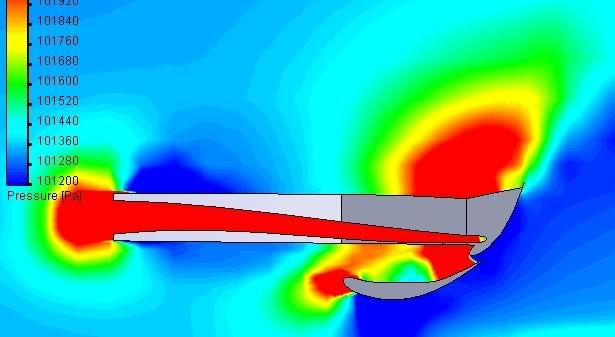

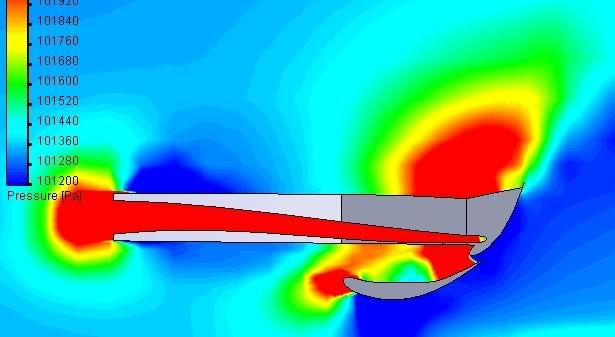

pressure is very high because of the dynamic pressure and flow restriction of the slot.

the flow re accelerates as it approaches the low pressure behind the wing, but still not enough to multiply speed by a big factor.

Ram effect can increase speed and pressure at the same time. Whenever both happens you know the air is being compressed by the car. Effectively Mclaren have an air compressor without the need for a secondary power source.

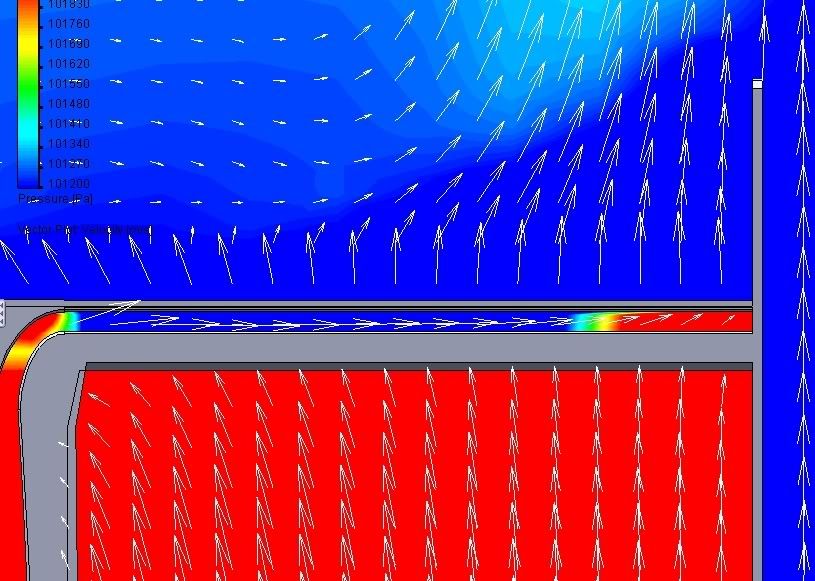

There is a drag penalty associated with the this as well, since the car is doing the work, Mclaren probably did a good job of finding a viable outcome with the drag saved by the flap.

I am still clueless about the design of the ducting of the slot. I know the cross section may be close to the coanda duct, in order that the air can leave the slot in some order.

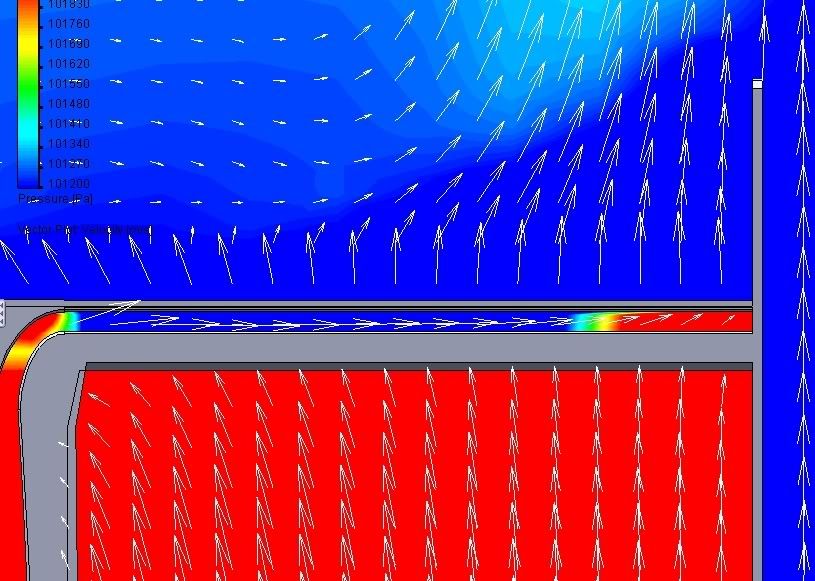

As can be seen, the damn arrows are barely leaving the duct.

The duct can only be a cavity as well, since the wing has to have 1 cross section beyond 75mm from center line.

The system Mclaren is obviously a refined system and may take a while to duplicate much less get the same effect. There are just too many things that have to be done right.

What i notice is that, blowing speeds of about the free stream barely change the flow on the element. Only bulging the velocity gradient. The flow momentum is so high that it takes about 3 times the free stream velocity to rip it of the element to stall it. The farther away from center the harder to stall as well.

I am puzzled by this whole system and think there is more to it than we know.

Next time i will just force it to stall and just take the readings.

I think that is more important than trying to duplicate the thing.