Basically every team is givin a 600watt 24v Motor tht spins at 2800rpm. now you would be forgivin for thinkin tht a vehicle with such power source is only going trundle along at electric wheelchair speeds but tht probably couldn't be more from the truth as i belive i could build 1 capable of 60mph however it may have to be slightly under geared so as not to run down the batteries too much because this is after all a 6hr race. i've so far got most of the chassis materials (pultruded carbon fibre tube for the suspension, Aerolam for the main body of the chassis and fibreglass box section for the roll bar and front crash structure) the plan is to get the overall weight below 40kgs minus batteries and driver.

but i've created this Topic so that i can seek your advice on aerodynamics i currently have a pretty good understanding of low speed aerodynamics and plan to do testing once the car is up and running however im planing on building the mk1 for under £1500 and due to time restrictions im planning on creating a plywood/foam bodywork for the Mk1.

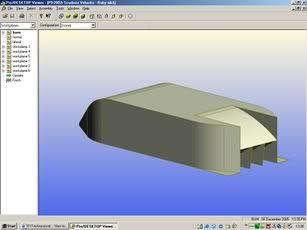

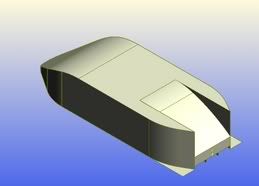

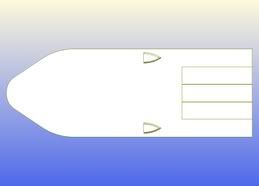

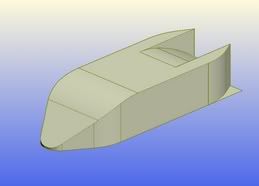

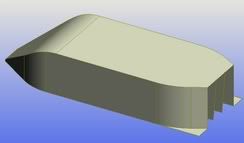

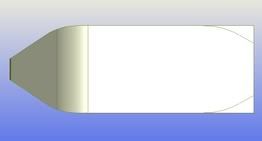

I'd appreciate it if u tell me what u think of this idea the wheels aren't shown but they'll be internal and i'll run it sumwhere between 30-50mm ground clearance. The driver is almost laying down inside. its 1000mm wide by 500mm high

Front

Trimetric

Plan

Underneath