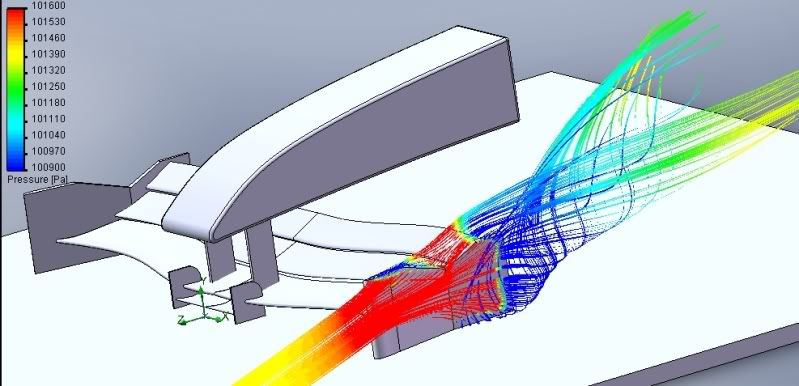

newbie wrote:great effort, but i stand by what i said about shedding the top edge vortex...the previous CFD image posted looks more representative of old F1 geometry and the mesh resolution was probably finer, better capturing the vortex behavior!

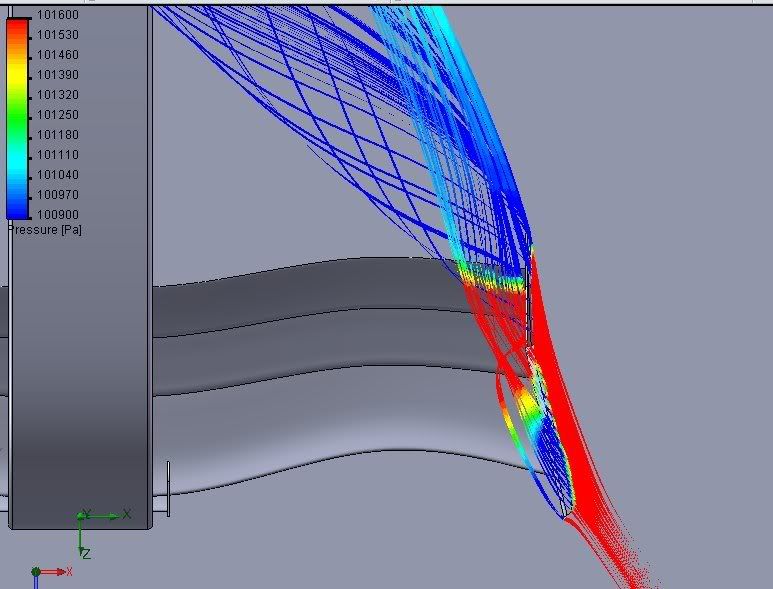

What do you mean exactly by shedding the top edge vortex? I see forced vortex shedding as something detrimental.

I know vortex can be beneficial in some cases, but with having the wheel right behind the plate. The vortex smashes right into the high pressure in front the rotating wheel.

I find the idea of distributing air over the elements more reasonable.

I am curious since Vortex shedding is something complicated, and in most cases it is an unwanted phenomena.

Concerning the mesh and the refinement of the cells, i tried, but it was too painfully slow.

And @ schumy7 about the pressure, it's not leaking pressure over the notch, if you look closely at the colour scale in the corner, and follow the colours; the notch is actually introducing high pressure over the wing element.

The blue is low pressure leeward side of the endplate that is sheilded from the flow, similar to the low pressure behind a car.

Check the red coloration from the top view.

I will run this again head on to get the vortex formation. I will also put a wheel behind the plate and see where the vortex goes. The vortex size is dependent on the thickness of the sheilded area behind the flow, the end plates are very thin so i won't be surprised if the vorteces are a little weak. But i am open to any opinion so hopefully i can try to observe more.

but it energizes air flow between the gap of the wing elements. It works for multi element wings i suppose. See how the weir of the notch is at the leading edge of the top element?