xpensive wrote:Whats BMW's solution WB?

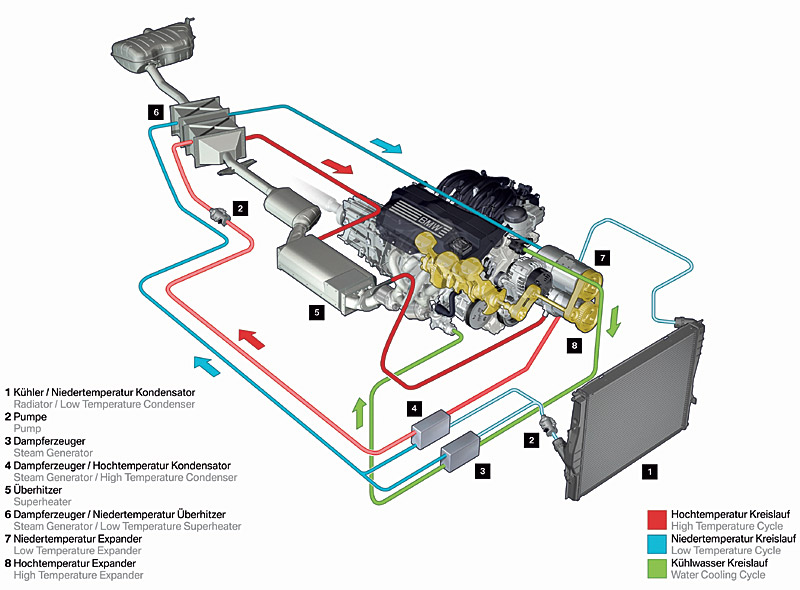

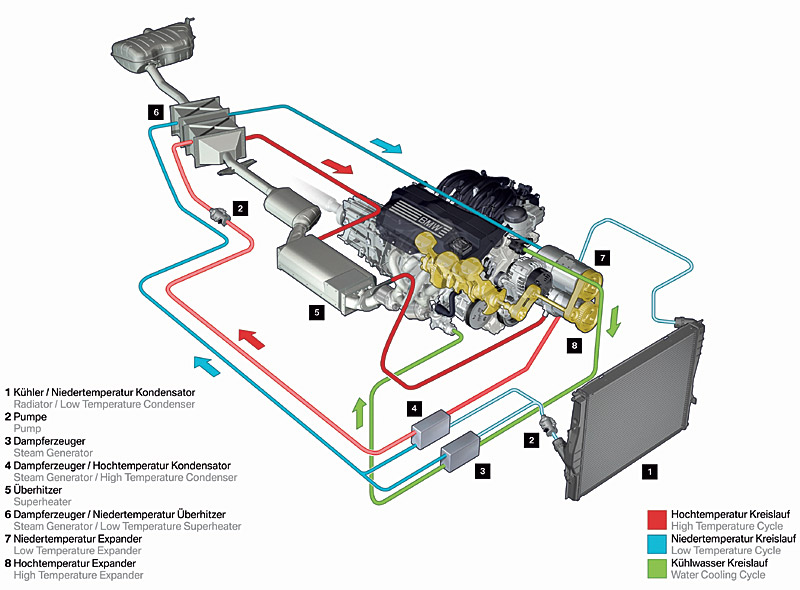

Their turbosteamer design used two secondary Rankine cycles with three recuperator stages.

Rankine cycle is a heat engine with vapor power cycle. The common working fluid is water. The cycle consists of four processes:

1 to 2: Isentropic expansion (Steam turbine)

2 to 3: Isobaric heat rejection (Condenser)

3 to 4: Isentropic compression (Pump)

4 to 1: Isobaric heat supply (Boiler/Recuperator)

They were planing to feed the recovered work from two steam turbines directly to the crankshaft of the engine.

This picture shows that they are actually using three stages of recuperation at 700 °C, 300 °C, and 70 °C with very high, high and low pressure.

Positions 3 and 4 are both condensers which shows that both circuits were using an evaporating fluid. The high pressure system may have used water and the low pressure system a refrigerant.

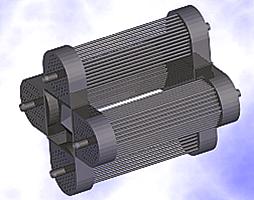

Here we see that the first recuperation unit had an exhaust temperature close 700 °C and the second unit 300 and 70 °C in separate circuits. The recuperation units are very bulky and probably very heavy.

So really the secret to HERS with an ICE would be a recuperator design that is highly efficient, low weight and low space. The turbo expander and the condenser would not be the problems. At the present state of the art you would probably need the weight and space of an entire engine for recuperation which makes it prohibitive.