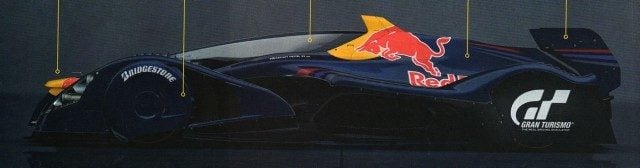

* Engine: gas turbine, 1483bhp @ 15,000RPM, 527lb ft @ 12,000RPM

* Transmission: continuously variable, rear-wheel drive

* Top Speed: 249mph

* Weight: 545kg

* Length/Width/Height: 4750/2180/980mm

* Suzuka Lap Time: 1:11.540 (compare with Vettel’s 2009 F1 lap time of 1:30.833)

* Special Features: enclosed wheels, “fan element” to increase low and medium-speed downforce (much like a vacuum cleaner)

Hmm? I wonder about that GT, if it's inspired from an existing machine?

This says nothing about fuel consumption since it's not restricted by any regulation. This car gives an idea of what Newey is considering when he thinks zero compromise.

Using this lap time with a 0.165kg/hp.hr consumption.

0.165*1483 hp*(71.54s * 53 laps /3600)hrs = 257 kg of fuel.

No problems here, we'll introduce refueling. Current lap record 1:31.54. The car can even afford to refuel every lap if needs be if it was racing the 2005 v10 cars.

However i think with a engine designed for 800hp, we can have a light weight 540kg car with major improvements in that 0.165kg/hp.hr consumption figure.

With the use of biofuels as well, it's possible that consumption wont even matter, seeing as though it's not fossil fuel. I still care for increased economy nonetheless.