747heavy wrote:I think it´s fair to say, that a sensor / flow meter for ~100kg/h would be a fair bit bigger then the shown 450mg/h flow meter above.

from the papers/data sheets which Edis posted of the aerospace flow meters, it becomes apparent that the liquid density and characteristics need´s to be know in great detail, to achieve high accuracy.

As they are volumetric flow meters, which compute mass flow on known characteristics (density, temperature etc.), if I understand this correct (which I may not).

As long there is no common fuel supplier in F1, and a fairly large range for fuel density under the current regs, this could prove difficult to calibrate and police beoyned doubt in an competetive envoirment such as F1 - IMHO.

Yep, that was my original concern. Each team may need to declare the fuel composition to the FIA confidentially, then the universal flow meter would be calibrated to each team based on the fuel sample the FIA usually collects.

I am still on the fence with the whole Mass flow restriction, but i think it's possible to overcome the problem.

These meters are not volume flow however. They depend on heat capacity.

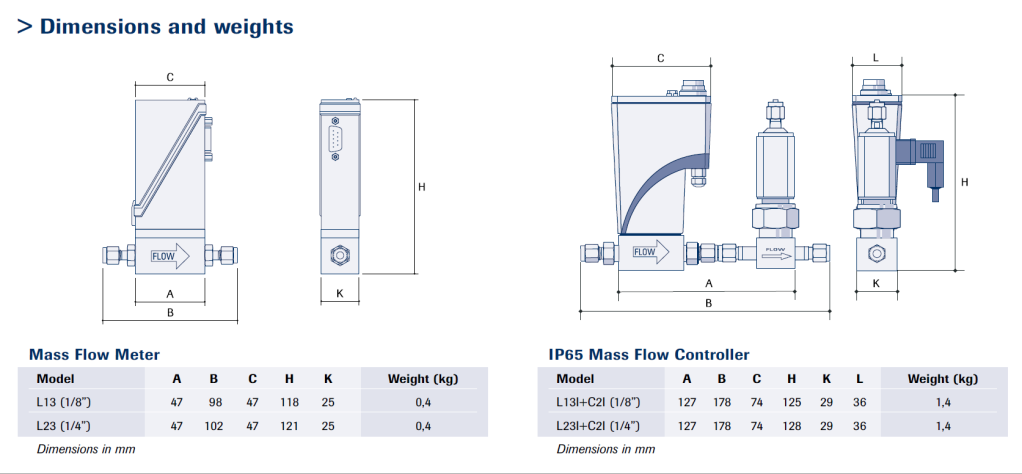

A flow meter for 100kg may be bigger indeed, but it may not be proportionally so.

Remember these are for water, gasoline's specific heat capacity is much less.

Gasoline is 2.22 kJ/kgK while water is 4.18, that's a factor of almost 2.

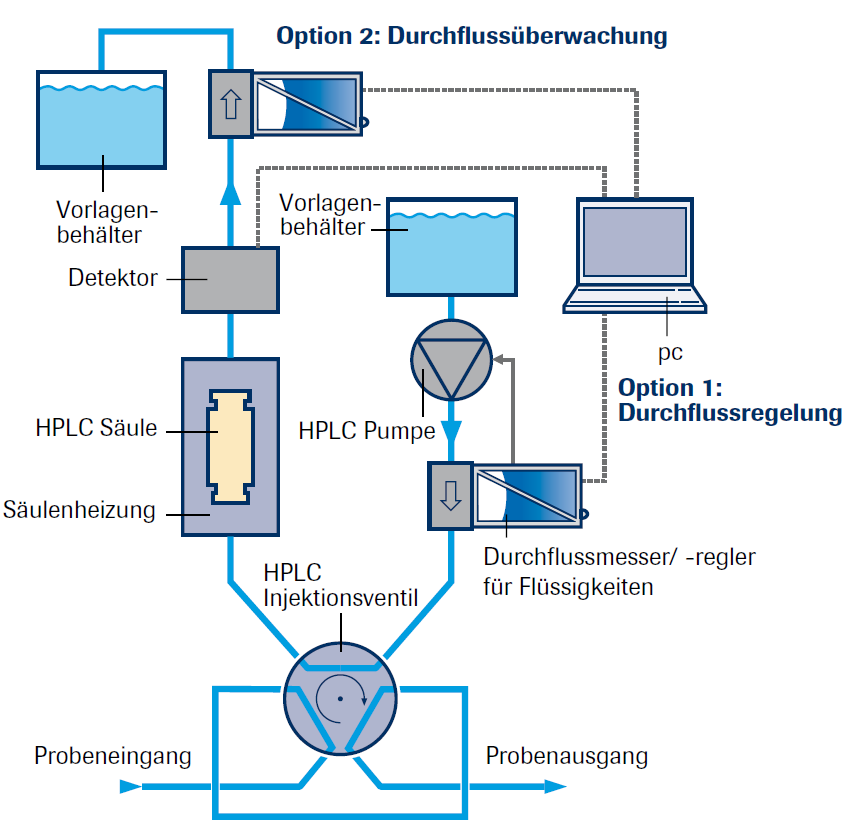

I was thinking about bypassing a portion of the fluid and measuring that as well ,even though there is a potential for teams to cheat with that idea.

Here's an example of a meter that can detect 25kg/hr. A little closer to the target, since it can measure about 50kg/hr for gasoline.

http://www.bronkhorst.com/files/publish ... es/l30.pdf

However this one can only take 100 bar of pressure and uses 8 Watts. And reading the article it can be seen that bypassing a fraction of the flow has it's technical problems as well.

I can see though, that with some millions in R&D, a device specifically for 100kg/hr and 500 bar of gasoline could be designed.

The Coriolis style meters now, are the cupboard sized equipment (about 90 w x 200 h x 261 l mm ). Those use vibration to detect mass flow. I think those are out of the question as well since an F1 car's environment is very harsh.

Kind of a waste of space just to detect fuel flow.

It can be done, but i wont pine over it if the whole idea is scrapped. Boost limit and max fuel allowance is good enough for me.