shelly wrote:why is temperature beneficial? we all agree on the fact that speed is an advantage , but how can be the gas being hot converted in some downforce gain? just by the fact that its density is lower?

I think we should talk a little about thermodynamics of this solution.

After combustion there is some energy added to exhaust gases. At pipes exit we see kinetic energy of flow (Ek=m*v^2/2) and internal energy of gases (temperature).

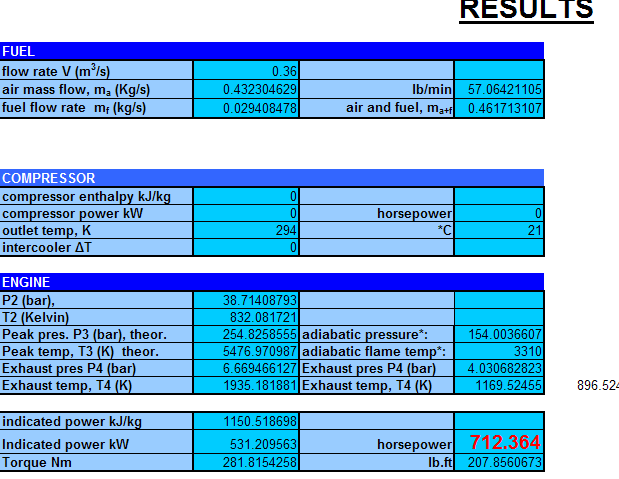

Even if we take ringo's numbers (220m/s, 850 degree), only roughly 4% of added energy is converted to kinetic energy, the rest being stored as gas internal energy.

There are many possible ways to use some of that energy (about 600-700kW for F1 engine) to do usable work.

One can for example try to get a volume of hot gases under the floor, and as gases cool down, they'll decrease volume (almost 4 times going from 1150K to 300K), working like a pump, sucking and speeding up surrounding air, decreasing dynamic pressure (downforce), increasing mass flow to diffuser.

I'm not telling we can use 100% or even 20% of that energy to create downforce - but every 1% gives you quite significant gain.