Giblet wrote:This is true of course, but now you have a harder exhaust to make, which are very carefully designed to be non-restrictive, will now be hard to make and have restrictions in the pipe. The rib would have to be large enough to get red hot and not fail.

I'm just thinking out loud if this will be worth any measurable gains for the amount of work.

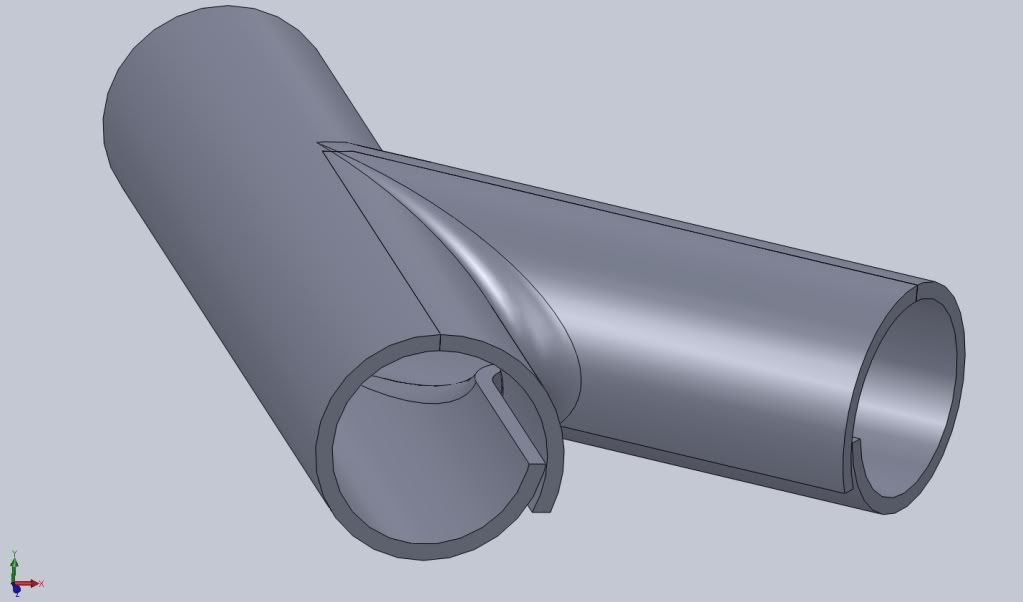

this is true, as the pipe has to made from an upper and lower hlaf then seam welded.

A skiiled exhuast maker can make it. It wil be more time consuming to make, but thankfully exhuasts don't get damaged as much as nose cones.

Chances are it may not need the rib. Having it split like this also means the pipe doesn't have any fluctating "hoop" stresses in the Y section.

Also, I wonder how much exhaust gas will divert to the first pipe as it will be high velocity, and choose the path of least resistance for the most part. My understanding is that the pipes are large enough for proper flow and very little back pressure.

I just don't know, so this is not so much a critique, as s genuine question of how and why this will work in the real world.

How much gas diversts where has to be based on experimentation. A little deflector, or a reshaping of the "Y" to get the desired flow ratios can be decided from experimentation.

I made this pipe as a nozzle, the diameter at the sidepod is bigger. The end is a bit smaller in diameter. There is a back pressure increase, but then there is a velocity increase.

I suspect that the F1 teams are doing this, especially renault. There is price to pay engine power wise, but you have an increase in exhuast velocity with the nozzle end. This increased velocity helps the diffuser.

It's probably blowing near transonic speeds i think at 18,000 rpm.

Serious!