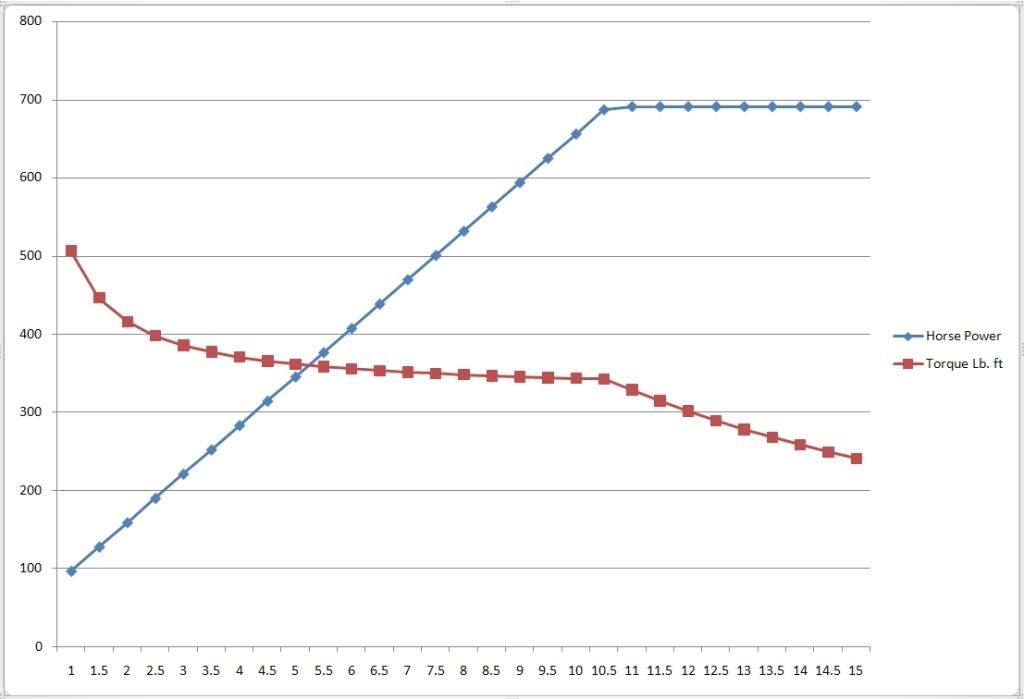

WhiteBlue wrote:I don't agree with the power and torque curve. The power will definitely reduce from 10,500 rpm. The friction will cause losses at higher rpms and the combustion efficiency is also likely to suffer.

Yes the friction will cuase problems. However you need correlations for friction losses for this engine. We don't have that data.

This graph is indicated power, not brake power. If it was brake power i would guess a mechanical efficiency of 80% or so. Though this will vary with speed.

I am still developing this simulator. So it will get better over time.

But i must tell you, the power graph is theoretical like this, as the engine has specific enthalpy. The power is a product of enthalpy and mass flow, so the power is directly proportional to fuel and air mass flow.

The first time i did the constant power engine, the power was dictating the fuel mass flow. This engine is the other way round. The fuel mass flow is dictating the air mass flow, hence the boost pressure required to stay in stoichometry.

The boost then dictates the inside cylinder conditions hence the specific enthalpy.

I'll try and include some kind of turbine data that varies with the air flow, that way things will look more dynamic. As you realize that the torque is increasing when the engine speed is lower. This is due to the turbine out put unrealistically running at full efficiency.

I'll also try to include some variable adiabatic flame temp in it. i'm no programer though so it'll take some time.

The turbo development is not so expensive as you may think. There are lots of restrictions to keep the cost down. You are not allowed to use variable geometries, multiple stages or exotic materials. It is pretty much the same situation as racing clutches or F1 brakes. All teams have access to competitive materials.

Yes that is true, but knowing that the compressor efficiency is a performance differentiator, i wont be surprised if millions are spent to create the best turbine and HERS. If NASA spend millions on simple airfoils, i doubt these turbo and compressor blades will get less attention.

The turbo, Intercooler and lubrication are most critcal here. Their influence really shows in any engine calculation.

edit, i also assumed a constant volumetric efficiency in these calculations. That is not the case in reality.