It shouldn't be aggressively concave, and i think we are looking at the diffuser incorrectly, ie more aggressive than it really is. It only needs to be concave near the throat with attached flow. The ultimate goal as i said is to have zero shear stress on the wall. Whatever shape achieves that is best for a given height, opening and length.

It can be concave for the first 5%, then convex for 30% and so on for example. It wont affect it much if it's mixed curvature, as long as the flow is attached.

Detached flow shouln't be on it, unless the height to length ratio is such that separation is unavoidable in a very very small region.

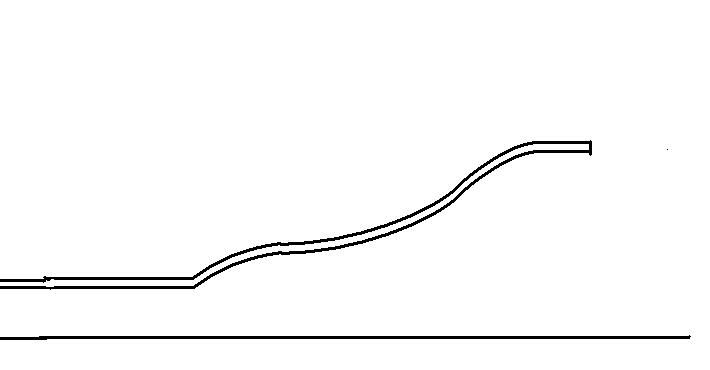

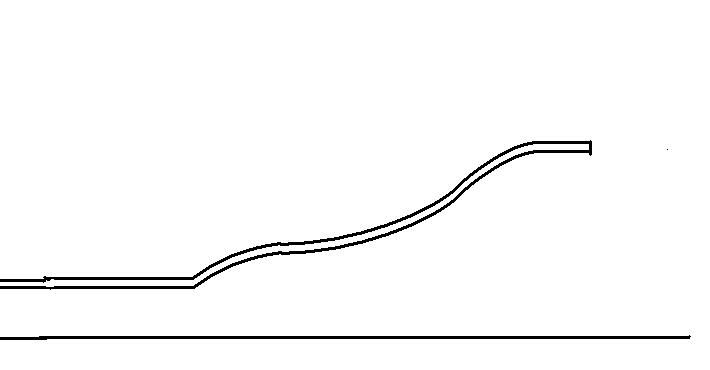

believe it or not this can be an optimized diffuser shape:

There are many variations, it's generally bell shaped and depends on the surface roughness, the dimensions of the inlet and outlet etc.

These things are computer calculated, but the whole idea is to have zero shear stress at the wall.

You can manually "feel around" with the cfd if you observe the friction at the surfaces. Again, the ideal is a bell shape for asymmetric diffusers based on research, not my experimeting.

At the end of the day we are talking about 1% is the starting design is fairly good. Nothing to beat up oneself over i guess.