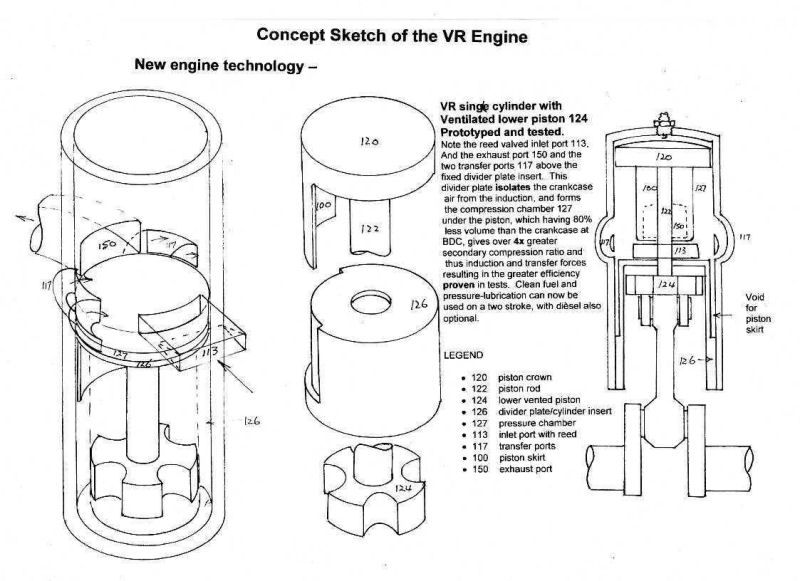

It's a fairly simple design that the inventor believes solves some problems of the 2 stroke. It uses a crosshead type piston enabling the bottom end (crankshaft and rods etc) to be lubricated as a 4 stroke engine typically is with the obvious advantages of keeping oil away from the combustion process as well as using cheap slipper bearings rather than roller cranks. The crosshead piston design allows a separate chamber to be incorporated as part of the crankcase using the lower side of the piston to act as a pump (supercharger), induction being via a one way valve (typically a simple reed valve is nominated). On the downward stroke, reed valve closes and charge is delived to combustion chamber via transfer ports as can be seen.

The inventor states that this allows pure air-petrol to be used without the usual oil mixed in that causes the pollution of a normal 2 stroke engine. He has mentioned how he lubricates the rings but was confidential and is not mentioned in the patent that I can see so I will not mention it.

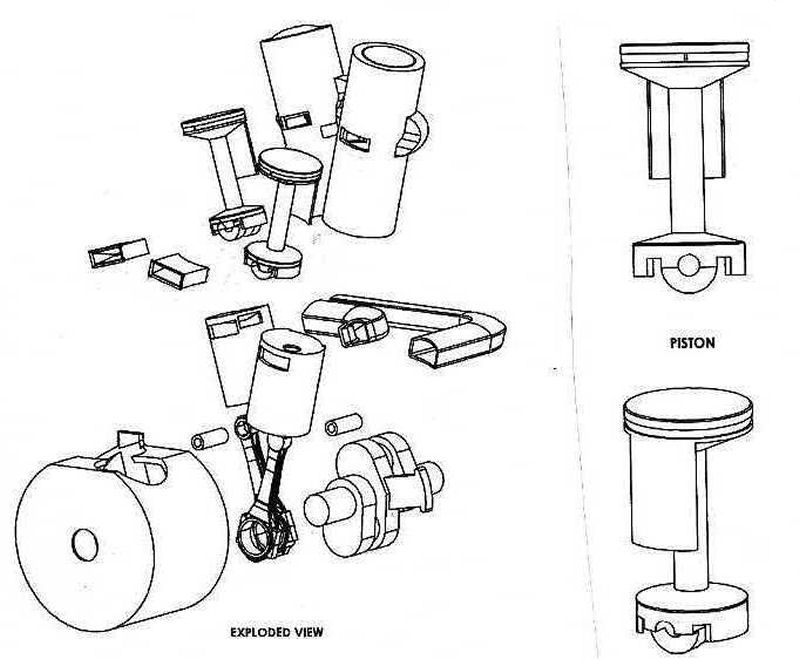

One of his innovations to save on pumping losses and costs in a twin cylinder version is to allow the fore'mentioned supercharging chambers to be connected by a port (after the reed valves) containing a throttle valve that can be manually opened and closed to operate as the throttle. The air in these chambers is merely transfered from supercharge chamber to supercharge chamber rather than a vacuum being created at part throttle therefore saving on pumping losses. No normal air/fuel intake throttle valve is required as the throttle valve in this transfer port is opened for low revs and gradually closed to encourage air to come past the reed valves increasing induction - the "Pivot Petal" drawn below...

Not just a drawing either, had a 100cc Yamaha based Kart engine running in this configuration.

What do I think? - as I told him ..

Being an older guy who has adoration for 2 stroke racing engines of the 60's, he falsely believes that crankcase compression is where it's at, he has about 4:1 currently - well this is 50 years later and it's well established that less than 1:5 is ideal to prevent the charge being blown too far up the exhaust port so a pressure wave (formed by the design of a 2 stroke exhaust) can return it effectively. Of course there will also be pumping losses but the other issue is heat, compress air to 4:1 and the heat has a dramatic increase, not good for anything and I believe that Nox will increase due to that(?).

The throttle'less system, while certainly has pumping loss improvement merits, also is a heat riser in an age where engine designers are trying to keep the combustion cooler to fight Nox.

He didn't much like me after that, seems to be a common trait with inventors

Oh and hello from the new guy, please don't like me now as it will save you time later