First of all, I am 4th year masters student at the University of Southampton (in england) studying Aeronautics & Astronautics with a major in aerodynamics.

My masters dissertation is designing and testing a 3rd scale open wheel race car (technically a hill climb car as there are literally no regulations so we get to decide what ever we want providing it fits in the dimension box), and my group just finish flow vis testing our car yesterday.

Flow vis is UV reactive but I think that's due to the nature of the chemicals, it's not really used to be shown under a black light, doesn't really help that much but it's made from a mixture of paraffin and ceramic powder and possibly a few other things.

Onto reading flow vis, people who say it's useless are fooled, the only way to get a more accurate picture of what's going on with the flow is to do PIV testing which is expensive and requires optical access to be used i.e. if the camera can't see it it wont get any data from it (and only works in a 2d plane) and every single F1 team uses flowvis on there wind tunnel models and there actual cars to gauge what's going on.

But when it comes to reading flowvis, it's down to aero knowledge, the flowvis plots the streak lines and it can show which way the flow is going, a relative speed, separation, vortexes and other things too.

Here are a couple of pics from my tests

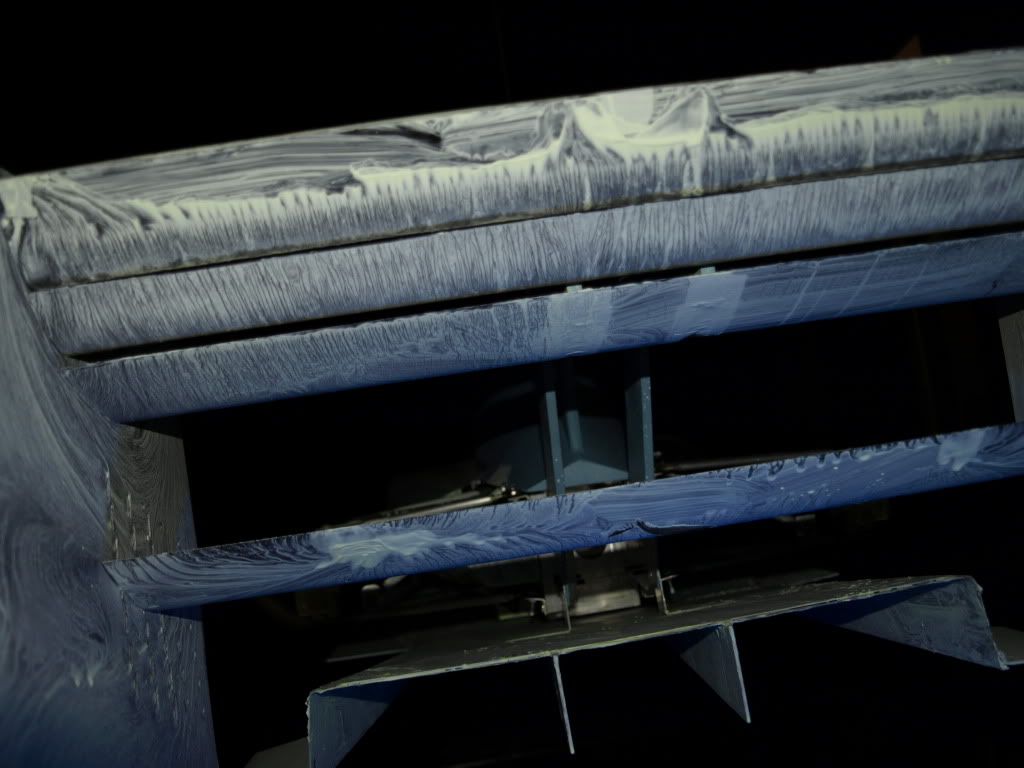

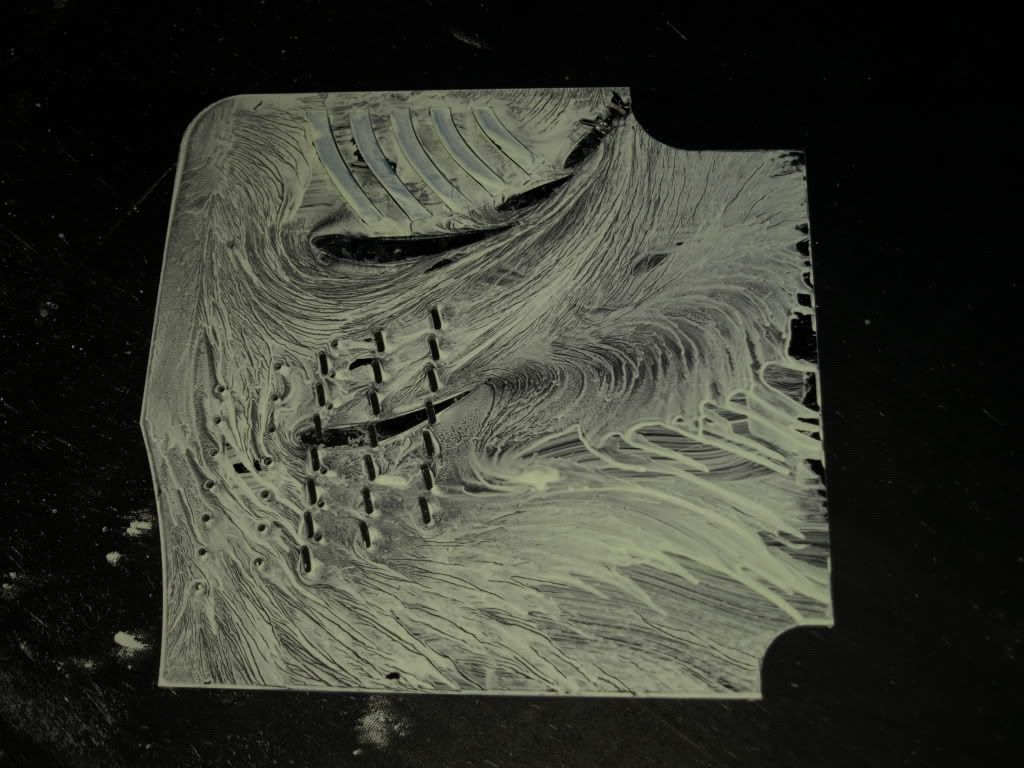

This is off the rear wing and the last element of the rear wing, it shows a clear region of separation on the trailing edge, now separation = drag but, if you look at the flow vis on the inside of the endplates

you can see that the streak line is still very close to the aerofoil meaning the separation bubble is very small.

The endplates also show that air in front of the upper plane is being sucked down and below the upper plane which mean there is a region of very low pressure on the aerofoil which is a very good thing but ye, i could write a fair bit about what those 2 pictures show and that's just 2 pictures of a whole car.

So to answer the question 'how to read flowvis' aero knowledge and experience utlimately

and here is a picture of the car we designed