marcush. wrote:audi has done this before with the R18 front difusser.It´s an aluminium machined part and skinned with some flimsy cf foils.

I´d think a foam core has more weight and you need a LOT more resinfilm to bond the skins with the core .So a skinned spar and stringer wing has considerable potential in terms of weight.

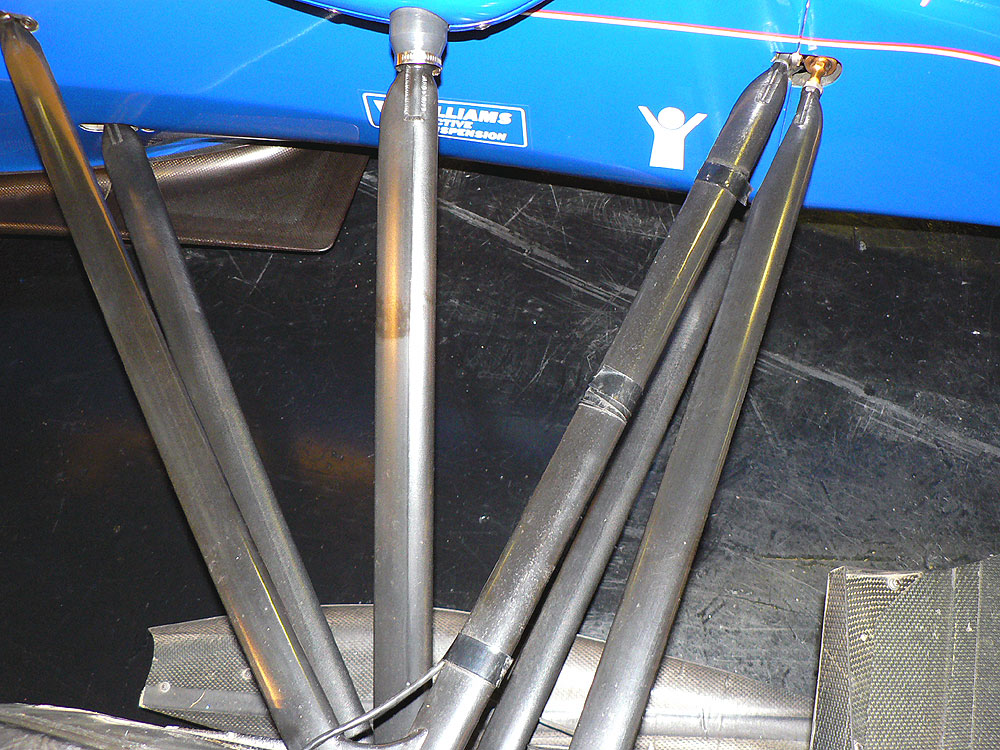

To build the spars and stringers from CF is elaborate -you need so many moulds for each and every piece..so maybe this is the firsrt step towards oing the full cf route.

Do you not think Audi made the wing from Machined aluminium to

add weight.

The trend in LMP1 over the past few years has been to run the same front and rear tyre size. This means you need a weight distribution of essentially 50:50 or certainly between 48% and 50% front. Having watched people lifting LMP1 nosebox/front diffuser assemblies vs. the equivalent part on a 45% front weight LMP2 car I've concluded that the nosebox assemblies of LMP1 cars are being intentionally ballasted and/or built with heavier materials.

In the case of the audi the fringe benefit of using a solid aluminium machined part is better dimensional accuracy of the part, particularly if it's vibrating I would imagine.

Ben