- Login or Register

No account yet? Sign up

Not true at all. Ferrari does, Mercedes does, the FiA does and a bunch of other people with some out of the box thinking do. You have to be pretty insular and ignorant of the great history of GP racing to not value road relevance.rjsa wrote:You know no one involvedin F1 gives a nickel to road relevance, right?

I'm not saying it doesn't have a benefit, I'm asking would VCT would be beneficial across that rev range (a genuine question).WilliamsF1 wrote:Cold Fussion wrote:Is VCT really that beneficial when you're only operating over the narrow range of 10k rpm to 12.5k rpm?WilliamsF1 wrote: Funny that every road car engine has some form of variable valve timing mechanism, but for the road relevant 2014 f1 engine it is banned by the FIA.

If it did not have any benefit then why ban them?

variable valve motion could allow modulated displacementCold Fussion wrote: Is VCT really that beneficial when you're only operating over the narrow range of 10k rpm to 12.5k rpm?

I'm not saying it doesn't have a benefit, I'm asking would VCT would be beneficial across that rev range (a genuine question).

The flow rate is all the same as you probably know very well. Anybody who speculates to profit from inaccurate measurement will be disappointed. The FiA is likely to require a fuel flow monitoring system that uses analogue and cumulative technology. This means it also measures and monitors between the digitised sampling points of the digital data logging system. The Gill sensor which was mentioned in the Renault V6 story and was advertised in RacecarEngineering is a good example for that technology.Tommy Cookers wrote:100 kg/hr means what ?

100 kg used over 1 hr ?

166.67 gm over 1 min ?

277.8 gm over 10 sec

27.78 gm over 1 sec ?

2.778 gm over 100 msec ?

0.2778 gm over 10 msec ?

this makes a big difference to performance

Speaking of road relevance. I remember that Gilles Simone in his "loud thinking" mentioned the small size of batteries (buffers as he calls them), 80mm maximum bore size and the potential of pneumatic valves for passengers cars.WhiteBlue wrote:Not true at all. Ferrari does, Mercedes does, the FiA does and a bunch of other people with some out of the box thinking do. You have to be pretty insular and ignorant of the great history of GP racing to not value road relevance.rjsa wrote:You know no one involved in F1 gives a nickel to road relevance, right?

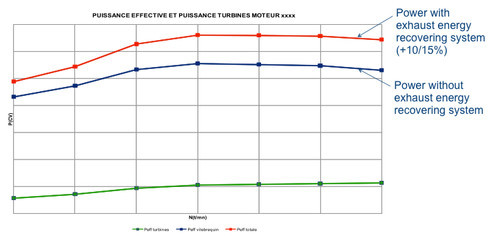

Source wrote:The turbocharger and power turbine are labelled TC1 and T1 respectively. Mechanical turbocompounding was used as opposed to an electrical system. The orange line labelled MC1 represents the mechanical link with a fixed gear ratio between the power turbine and the crankshaft. The results of the simulations are presented in Figure 5. The turbocompound engine performance is plotted along with the turbocharged engine performance for comparison purposes. From 6,500 rpm the turbocompound engine produces more torque and power. However, it is only from 8,000 rpm that here is a significant increase in output. The output increases by 26.7 kW and 27.7 Nm on average which represents a 7% power increase and 6% torque increase in the range where the engine spends over 85% of its life. There is a peak increase of 31.5 kW and 31.7 Nm at 9,500 rpm. At the most useful speed, 8,500 rpm, there is an increase of 26.5 kW and 29.8 Nm which translates into a 6.5% increase to both power and torque. Since here is an increase in power for the same fuel consumption, the BSFC is lower for the turbocompound engine. It is important to note that the gear ratio of the mechanical linkage was optimised to get the highest value possible for the power at 8,500 rpm.

Source wrote:While turbocompounding adds power at no extra fuel cost, it adds weight to the vehicle. The mass of the added components to the turbocharged engine is estimated at 16.5 kg. It is commonly known that there is a time penalty of

around 0.3 seconds per lap for every 10 kg added to the car. Adding 16.5 kg to the car would theoretically slow it down by about half a second a lap. However, Formula One cars carry 30-50 kg of ballast in order to reach the minimum weight. The

weight of the turbocompound system is subtracted from the ballast and the result is a higher centre of gravity. Increasing the centre of gravity by 10 mm will result in a time penalty of 0.1 second. However, the 2010 F1 technical regulations state that the centre of gravity of the engine must not liebelow 165 mm and the we

FiA wrote:5.4 Weight and centre of gravity :

5.4.1 The overall weight of the power unit must be a minimum of 145kg.

5.4.2 The centre of gravity of the power unit may not lie less than 200mm above the reference

plane.

5.4.3 The total weight of the part of the ES that stores energy, i.e. the cells (including any clamping plates) and electrical connections between cells, must be no less than 20kg and must not exceed 25kg.

5.4.4 When establishing conformity with Articles 5.4.1, 5.4.2 and Appendix 4 of the F1 Sporting Regulations, the homologated power unit perimeter will be defined in accordance with the table shown in Appendix 2 of these regulations.