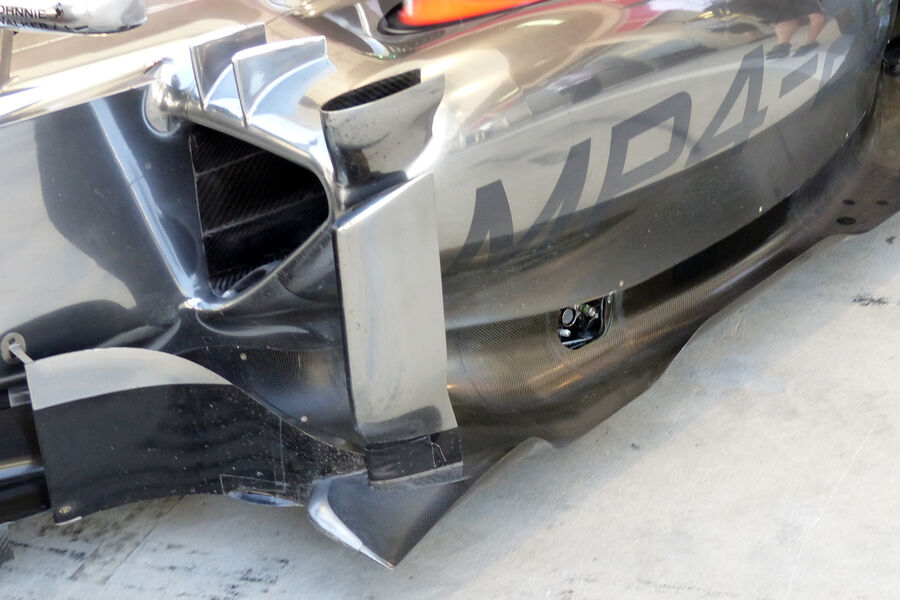

Holm86 wrote:Lycoming wrote:Is that a strain gauge I spot on the pullrod? If so, it might explain why they're steel... it's much less involved to calculate load when the material being strain gauged is isotropic.

First when I saw that picture I thought is was adjustable. So that they could adjust ride-hight on the pullrod itself.

Usually, your adjustment mechanism is at one of the ends, not in the middle. You either have a threaded rod end that threads into a threaded insert welded/bonded to the rod with a jam nut to secure it, or (I suspect this is what all F1 teams use) an alloy fitting that allows you to slot in shims to change ride height. With carbon arms, you would have this at one of the ends because you need an alloy insert there anyways to install a ball joint so you con bolt it into the rocker or upright. Your carbon pullrod will be ride height adjustable, so I don't understand why you would make it steel for that reason.

When I first saw that pic, the thing in the middle looked like the kind of thing you would use to wrap over a strain gauge, and the middle of the pullrod is the best place for a strain gauge, but looking at the picture more closely, that does not appear to be the case. It appears to be something that can be... moved or adjusted. Maybe it lets you change it more quickly? But any ride height change means getting out a set of scales, so it won't be that quick...

I'm not really sure what to think anymore. Maybe should think about going to bed.