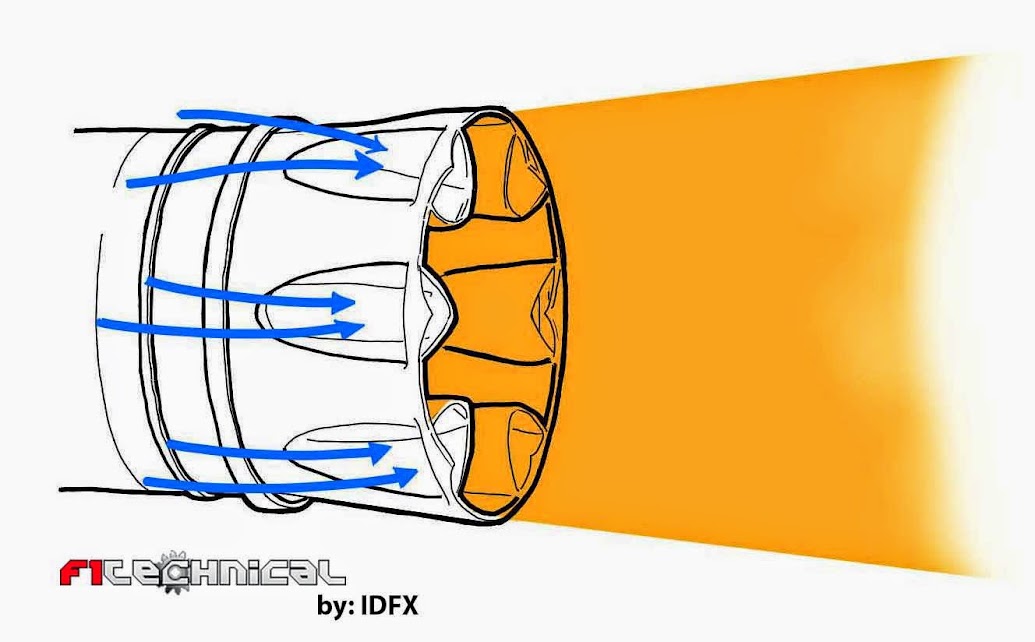

You can see one on this Rolls-Royce BR710 engine:

Offtopic ->Tim.Wright wrote:I always worry when I see painstakingly detailed renderings of a new idea...idfx wrote:create some vórticesLycoming wrote:What's the purpose of that geometry?

If you want to slow the car down by introducing more drag, it would be easier to put a hoizontal barn door between the rear wing endplates.

BTW I'm sure this is illegal too. If I remember correctly the last 100mm or so needs to be a straight section of round tube.

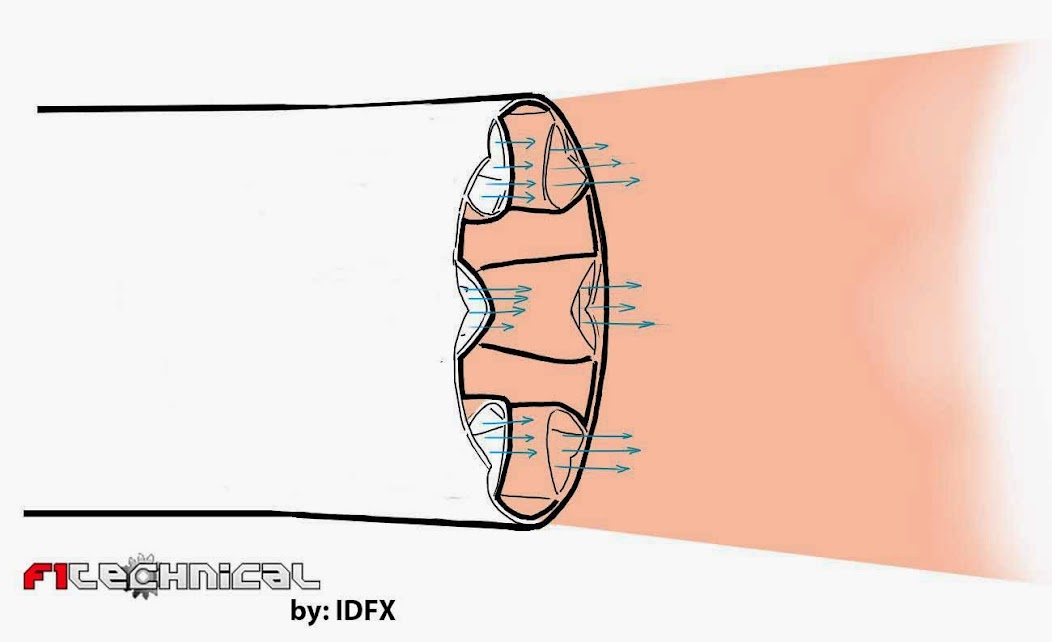

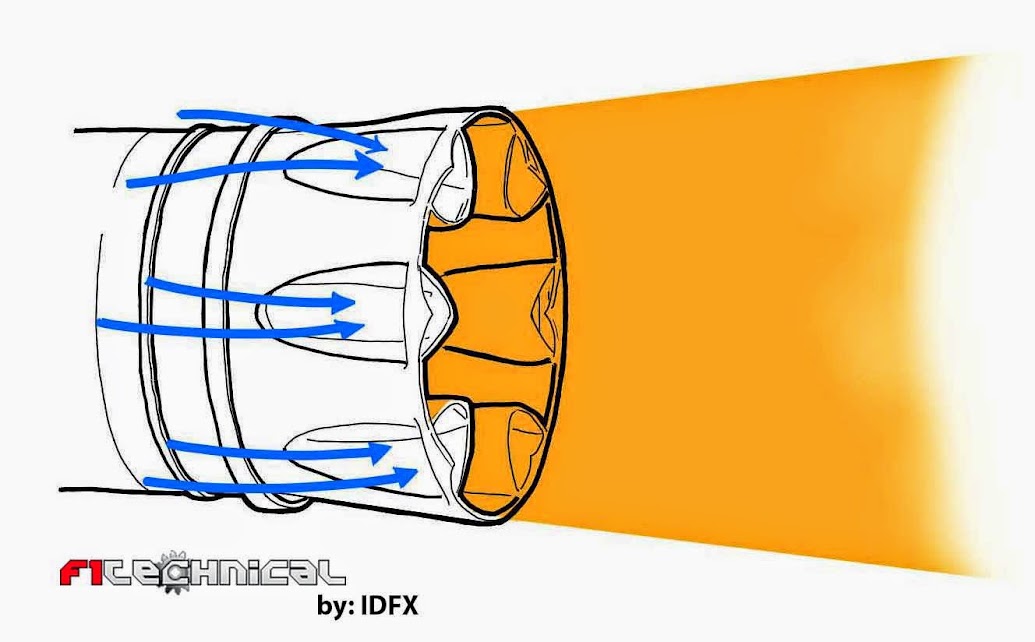

As I understand it the point of mixing the flow is less about reducing the energy spent creating sound and more about changing the frequency of the sound, mixing the flow creates a high frequency sound which is harder to hear because higher frequency sounds require more energy to generate and do not travel so well in air. All wings create sound because the boundaries layers and the wake itself all oscillate. A gurney flap would create sound but nothing like what you are looking for - for a bit of comparison, most of the sound you hear when a plane is coming into land above you is the sound of drag, not the sound of the engines which are often near idle position.Holm86 wrote:So if mixing the flows reduces the noise, will separate the flows work the other way round?? For instance having a gurney flap (lacking a better word in this case) around the tailpipe exit. Could that increase the sound of the exhaust??NoDivergence wrote:The mixing is not a new concept, but imo, will not have much advantage here. The primary benefit for aircraft that have echelons on the turbofan cover is that the mixing flow allows for a significant noise reduction

Mostly correct. It takes energy to produce noise. Noise is basically acoustic energy propagating through the air. With turbofan aircraft engines, the exhaust noise is mostly produced from significant turbulence created when the high velocity exhaust gas flows pass over the sharp edge of the exhaust duct and mix with the lower velocity bypass airflows. What the daisy mixer does is rapidly expand and slow some of the exhaust flow so that it creates less turbulence (and noise) when it mixes with the bypass flow. The trade-off is reduced efficiency in the exhaust flow.thepowerofnone wrote:As I understand it the point of mixing the flow is less about reducing the energy spent creating sound and more about changing the frequency of the sound, mixing the flow creates a high frequency sound which is harder to hear because higher frequency sounds require more energy to generate and do not travel so well in air. All wings create sound because the boundaries layers and the wake itself all oscillate. A gurney flap would create sound but nothing like what you are looking for - for a bit of comparison, most of the sound you hear when a plane is coming into land above you is the sound of drag, not the sound of the engines which are often near idle position.

Consider this extreme example: Imagine if the engine was able to operate effectively with exhaust valve timing where the valve did not open until the gas pressure in the cylinder had been expanded to just above atmospheric level. This would basically mean that almost every last bit of energy existing in the combustion gas had been extracted by the piston, and the exhaust gas volume remaining in the cylinder would need to be pushed out the exhaust manifold by the upstroke of the piston. Such an engine would produce virtually no exhaust noise.n smikle wrote:So Riff-raff,...Since they reduce Noise, one can say then, that daisy mixers on the exhaust tips are not what we want in Formula 1.

I could be wrong.riff_raff wrote:Consider this extreme example: Imagine if the engine was able to operate effectively with exhaust valve timing where the valve did not open until the gas pressure in the cylinder had been expanded to just above atmospheric level. This would basically mean that almost every last bit of energy existing in the combustion gas had been extracted by the piston, and the exhaust gas volume remaining in the cylinder would need to be pushed out the exhaust manifold by the upstroke of the piston. Such an engine would produce virtually no exhaust noise.n smikle wrote:So Riff-raff,...Since they reduce Noise, one can say then, that daisy mixers on the exhaust tips are not what we want in Formula 1.

What your ear perceives as exhaust noise is a pressure wave that propagates thru the air from the exhaust pipe outlet to your eardrum. The pressure wave exiting the exhaust pipe is produced by the rapid discharge of high-pressure exhaust gas from the cylinder when the exhaust valve opens, which is well after the combustion event occurs. Since there is only air between your eardrum and the engine, the acoustic energy must ultimately be transferred thru this gas.idfx wrote:I could be wrong.

the sound occurs one previous cycle. the explosion cycle. part of the sound propagates around the engine area. And part of the sound of an engine is created by transferring or resonance. -> solid, liquid and gaseous.

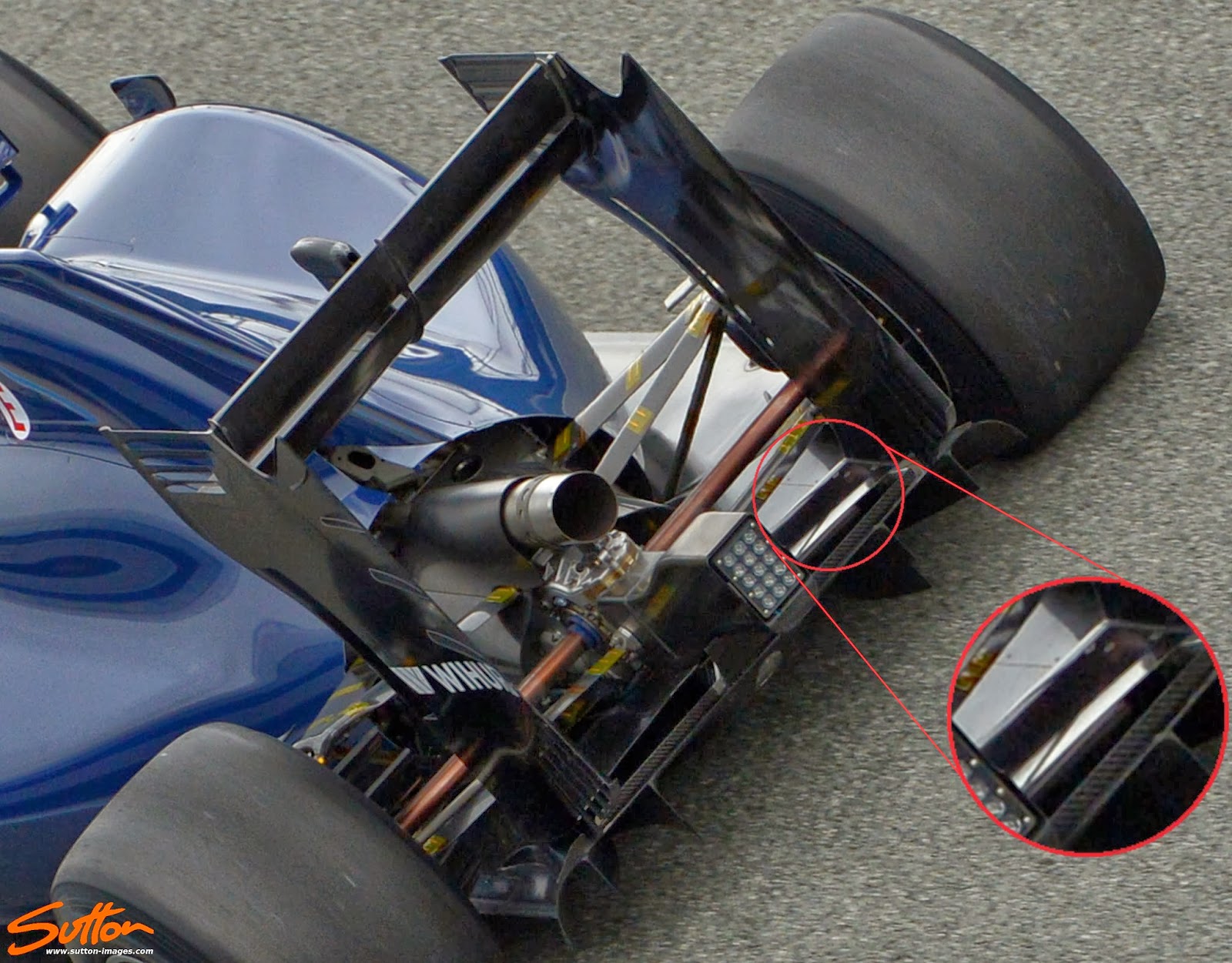

Could be some device to de-swirl/straighten the exhaust flow. The exhaust flow exiting the turbine has a substantial tangential velocity component. When this flow exits the exhaust pipe just a short distance away it will still have a helical flow path, and this helical flow may produce some aero unbalance at the rear of the car.thisisatest wrote:what's under the wrap? looks a lot like what's being drawn.

About the photo: image of the inside?thisisatest wrote:what's under the wrap? looks a lot like what's being drawn. (pic courtesy of Stefan_ in the Williams thread)

http://i.imgur.com/yl9eMRS.jpg

don't the gaps at the edge of the wrap look like this pic?

https://lh4.googleusercontent.com/-b4zG ... ust+02.jpg