You may like to think (or dream) about this application:

It is an Opposed-Piston PatATi Portable Flyer having

80mm bore,

80+80=160mm stroke,

800cc,

540mm crankshaft axis to crankshaft axis distance (two directly-driven counter-rotating propellers, 1m diameter each),

perfectly "vibration free" and "reaction free" structure,

total weight less than 15Kp (33lb).

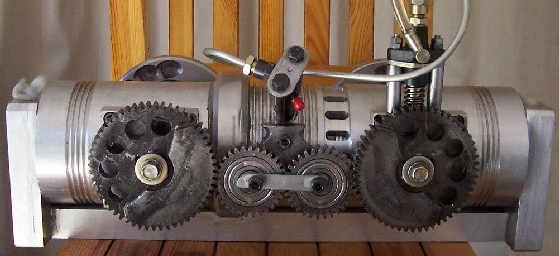

The second GIF is the one half of the Opposed Piston PatATi engine and shows the "internals".

The narrowing at the center of the cylinder of the OP PatATi engine enables a compact combustion chamber without spoiling the - loop - scavenging. The spark plugs are located more centrally. The narrowing causes the required squeeze during the combustion.

Without phase difference between the two crankshafts (yet, with asymmetric transfer and intake) and with the same instant pressure acting on the two piston crowns (common combustion chamber), the synchronizing mechanism (not shown) between the two crankshafts runs unloaded, so it can be lightweight and reliable, causing minimum power loss.

The two counter-rotating propellers act as the flywheels of the engine.

With the two oppositely moving pistons counterbalancing each other, the balance webs on the crankshafts have to balance only the mass of the crankpin and of the rotating part of the mass of the connecting rods (lightweight and compact crankshafts).

At 5,000rpm the speed of the blade tip of the 1m diameter propellers is 260m/sec.

With 0.5Kg reciprocating mass per piston (it includes the mass of the piston, of the wrist pin and of the "reciprocating part - typically 1/3 - of the connecting rod) the resulting maximum inertia force is 700Kp at the TDC (at the BDC the inertia force drops to 400Kp; con-rod to stroke ratio: 2). In comparison, with only 20 bar pressure inside the cylinder (20 bar is the BMEP - brake mean effective pressure - in the typical marine two-stroke supercharged engine), the resulting pressure force on each piston is 1,000Kp.

Application:

Imagine a pilot / rider wearing a wingsuit and having secured on his shoulders this Portable Flyer, flying only 2m above the sea (for safety) from island to island.

The pilot / rider can take off vertically, like a helicopter, and then he can progressively turn to horizontal fly, like an airplane, to cover the distance quickly and fuel efficiently (fast and cheap).

At landing he returns to "helicopter" mode to land vertically.

For more about the PatATi Aymmetric Transfer and Intake: http://www.pattakon.com/pattakonPatAT.htm

Thoughts?

Thanks

Manolis Pattakos