TechF1 wrote:http://www.omnicorse.it/img/articoli/ev ... entati.jpg

Wow finally... maybe was Tombazis that told to Marmorini to do not install coibentation

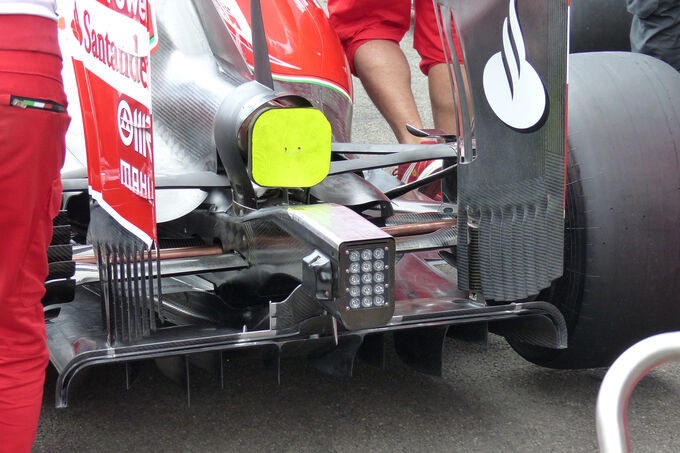

Looks sloppy...the large gaps ??? Maybe the installation isn' finished.

TechF1 wrote:http://www.omnicorse.it/img/articoli/ev ... entati.jpg

Wow finally... maybe was Tombazis that told to Marmorini to do not install coibentation

With electric motors the trend is to run more rpm. The same power at lower rpm means more torque and more heat. Heat hurts the efficiency of electric motors efficiency more than rpm associated friction. TBH I don't know much about electric motors because I waited till I was 31 yrs old to start on my engineering degree so I haven't worked much with electrics yet.trinidefender wrote:The higher the rpm that the motor has to run at the higher frictional losses it will encounter, this reduces its efficiency and hence power to the wheels. If you place the ERS-K next the to engine then a lot more cooling is needed for the ERS-K as well as heat shielding between the motor and the engine. 3rd'ly placing it next to the engine would be slightly eating away into available radiator space which might make the side pods bigger so the worse aero part is arguable either way.PlatinumZealot wrote:wesley123 wrote:Due to the use of computers and limitations set over the weekend(Parc ferme) ease of setup isn't much of a design consideration anymore. Teams always come to races with a setup that works or close to works, requiring much less setup times.

The packaging within the gearbox casing just works better aerodynamically, and that is pretty much it's only consideration.

Putting kers motor in the gearbox will take up a lot of space! It is defintely worse aerodunamically. Not to mention if you decide to mount the motor transversely you have to run it at ring gear speeds which is much lower than engine speeds. This is not good as slower rpm motors need to be larger to make the same power as high rpm motors.. Soooo is in tour best interests to have a high rpm motor. Which mean you place it beside the engine.... Takes up less space and reduce the car's polar moment of inertia.

Overall I would think running a slower more efficient ERS-K motor that requires less cooling and heat shielding further increasing efficiency of the system as a whole in the gearbox , while it might be slightly heavier, would be a neat system and something that makes sense in my head. Hmmm I wonder if ever anybody will be able to confirm if in fact their ERS-K motor is in the gearbox.

Which is why the gearbox is both longer as well as higher.PlatinumZealot wrote: Putting kers motor in the gearbox will take up a lot of space!

Instead of taking up space in the sidepod or wherever they package these things it now is packed within the gearbox, far away from the airstream and not taking up space in the sidepodIt is defintely worse aerodunamically.

Do you know if the ERS-K is a DC or AC motor? A slower turning motor does not always equal more heat.Pierce89 wrote: With electric motors the trend is to run more rpm. The same power at lower rpm means more torque and more heat. Heat hurts the efficiency of electric motors efficiency more than rpm associated friction. TBH I don't know much about electric motors because I waited till I was 31 yrs old to start on my engineering degree so I haven't worked much with electrics yet.

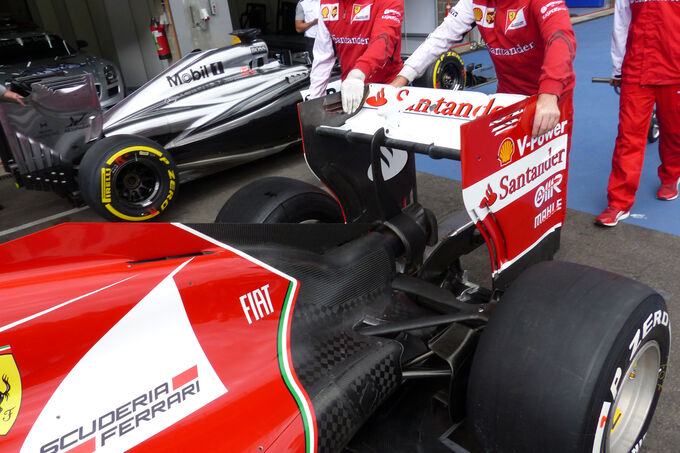

stefan_ wrote:Belgium 2014 - Thursday (21.08.2014)

brushless DC motortrinidefender wrote:Do you know if the ERS-K is a DC or AC motor? A slower turning motor does not always equal more heat.Pierce89 wrote: With electric motors the trend is to run more rpm. The same power at lower rpm means more torque and more heat. Heat hurts the efficiency of electric motors efficiency more than rpm associated friction. TBH I don't know much about electric motors because I waited till I was 31 yrs old to start on my engineering degree so I haven't worked much with electrics yet.

In the world of Formula 1 weight is the enemy. And high rpm motors don't have juge windage losses like high rpm engines so you can't infer that they will be less efficient than low rpm motors. They are still very efficient despite being faster. And no... a slower motor won't be slightly heavier.. it will much..much heavier!trinidefender wrote:The higher the rpm that the motor has to run at the higher frictional losses it will encounter, this reduces its efficiency and hence power to the wheels. If you place the ERS-K next the to engine then a lot more cooling is needed for the ERS-K as well as heat shielding between the motor and the engine. 3rd'ly placing it next to the engine would be slightly eating away into available radiator space which might make the side pods bigger so the worse aero part is arguable either way.PlatinumZealot wrote:wesley123 wrote:Due to the use of computers and limitations set over the weekend(Parc ferme) ease of setup isn't much of a design consideration anymore. Teams always come to races with a setup that works or close to works, requiring much less setup times.

The packaging within the gearbox casing just works better aerodynamically, and that is pretty much it's only consideration.

Putting kers motor in the gearbox will take up a lot of space! It is defintely worse aerodunamically. Not to mention if you decide to mount the motor transversely you have to run it at ring gear speeds which is much lower than engine speeds. This is not good as slower rpm motors need to be larger to make the same power as high rpm motors.. Soooo is in tour best interests to have a high rpm motor. Which mean you place it beside the engine.... Takes up less space and reduce the car's polar moment of inertia.

Overall I would think running a slower more efficient ERS-K motor that requires less cooling and heat shielding further increasing efficiency of the system as a whole in the gearbox , while it might be slightly heavier, would be a neat system and something that makes sense in my head. Hmmm I wonder if ever anybody will be able to confirm if in fact their ERS-K motor is in the gearbox.