Interesting for sure.wuzak wrote:I was given this link on another forum.

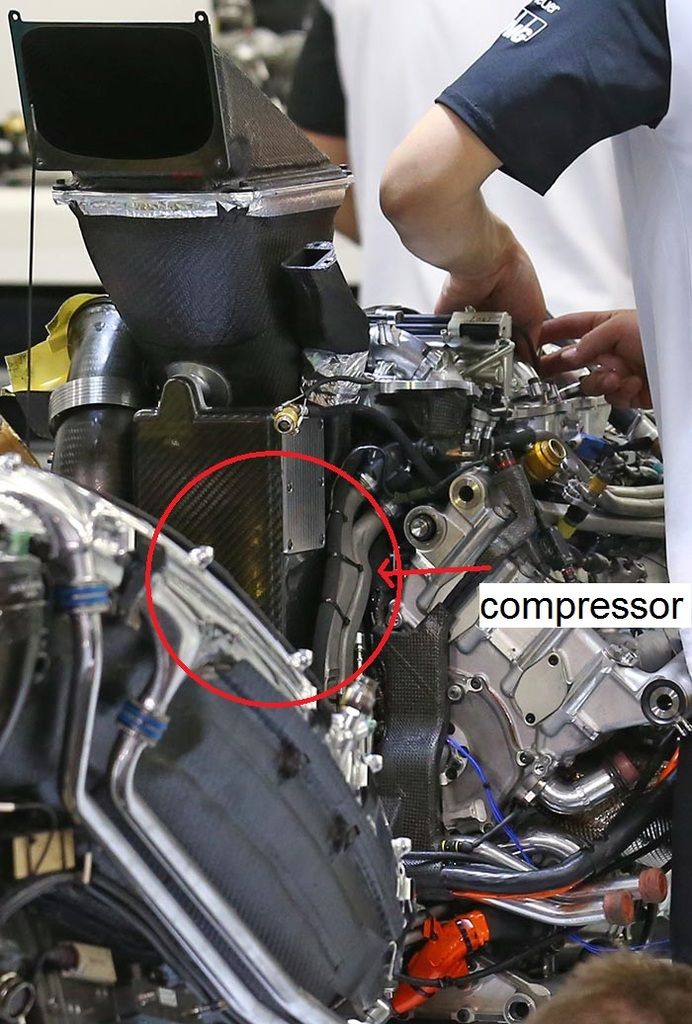

It suggests an elongated axial compressor, which possibly sounds like a diagonal compressor.

Ever since the idea fo the axial compressore showed up in rumors I've been thinking how a "longer" compressor wheel and blades would work, obviously tapered to the high pressure side (both the housing and the wheel/blades on the wheel). However, it seems desperately prone to stalling if you ask me. On the other hand, that sort of stuff is not exaclty my wheel house, so my feeling might be off. Additionally, if anyone can finde a clever solution for this problem via CFD simulation it is someone within F1.

One particular thing in the posted article, however, seems illogical to me. Namely making the inlet plenum out of aluminium to reduce the heat transfer between the top mounted radiator and the inlet air. I mean, as metals in F1 cars go, aluminium is the best at conduction heat there is. Carbon fibre is far worse at it (or better if you want to insulate) and can be very neatly coated with ceramic insulations that can even be made reflective as well. Hence the silver or gold coating on a lot of cars these days (if you're interested, check out zircotec, they've got some nice illustrations and videos).

And also: a carbon fibre part would not necessarily be that much more difficult to manufacture, just way more time consuming. I'd bet that McLaren wouldn't even flinch at the request to make this exact part out of carbon fibre. So, why make it out of aluminium? Seems awfully difficult to manufacture to me (milling big aluminium parts with very thin walls is a bitch). Structural integrity should be better with a properly designed carbon fibre part as well. Maybe there are some weird load bearing paths in it, I don't know. If that thing is indeed the inlet plenum with full charge pressure inside it (as mentioned before, I'd say not), it might be an issue with blowing the carbon fibre piece apart. But, again, I'm sure that McLaren would know how to build this thing out of carbon fibre with considerable weight savings. Might just be a case of "let's deal with weight later".