Hello LucF.

Given that Ryger knows that a technical solution officially filed in a patent office is protected, what is all this “secrecy” for?

The 80% less emissions is not an answer; it is an advertising trick.

Unless Ryger engine has 80% less emissions than the “current 2-stroke” Rotax 800 E-TEC.

He could simply give the gr/kWh of HC, CO, NOx and CO2 at some conditions.

The same for the “can go far more than 30k” while its breathing capacity (power) drops after 18,000rpm. Suppose it “can go far more than 50k or 100,000rpm”; then what?

You write:

“For new engine designs keep always in mind the following.

All nice designs you show us, but all to complicated and therefore to expensive to introduce in this automotive world.”

Thanks for the advise and for the opportunity to explain how things are.

Take the PatMar 2-stroke:

(the details and the granted patents (wherein more technical details are available) are at

http://www.pattakon.com/pattakonPatMar.htm )

With 86mm bore and 210mm stroke (uniflow, stroke to bore ratio 2.5:1, short connecting rod, cross head architecture), the capacity per cylinder is 1164cc.

An even-firing 4-in-line (4.6lt) is as vibration free as the best V-8 4-strokes.

There are many technical reasons for being cleaner not only than the “current 2-stroke designs” as Ryger claims for his engine, but also than the state-of-the-art 4-strokes.

And there are many technical reasons for having lower specific fuel and lube consumptions than the current 4-strokes.

For instance, during the combustion, the total wall surface around the hot gas and the burning fuel is similar in size with that of a conventional 2lt 4-stroke 4-cylinder Diesel engine.

Or, for instance, think the friction loss saving as compared to a similar power 4-stroke.

Is the PatMar too complicated / expensive to introduce in the real world?

Think it as a truck engine making its peak power at 2,000rpm (14m/sec mean piston speed).

It is way simpler and cheaper than the current 4-stroke truck engines (with the same mean effective pressure, a 4-stroke needs double capacity in order to make the same power at the same revs).

Quote from

http://www.pattakon.com/pattakonPatMar.htm

With the "pants", the state-of-the-art low speed two-stoke marine and power station engines (like the Wartsila - Sulzer, the MAN B&W etc)

which are the by far most efficient stand alone working machines today, become:

- even more reliable (increased scuffing resistance, longer time between overhauls),

- cheaper and simpler (no special equipment and control for the cylinder liner lubrication),

- more economical (lower lubricant specific consumption),

- greener (less lubricant into the combustion chamber, better combustion, reduced emissions).

With the "pants" the low-speed two-stroke engines combine their own advantages with those of the medium-speed four-stroke engines.

End of quote.

By the way,

in a previous post (August 16, 2015) regarding a “new 2-stroke design” of Honda:

the most obvious issue is the low revving capacity (even for small engines) due to the poppet exhaust valve and its actuation mechanism (a two-stroke poppet valve opens and closes at double frequency than a 4-stroke poppet valve engine operating at the same revs)..

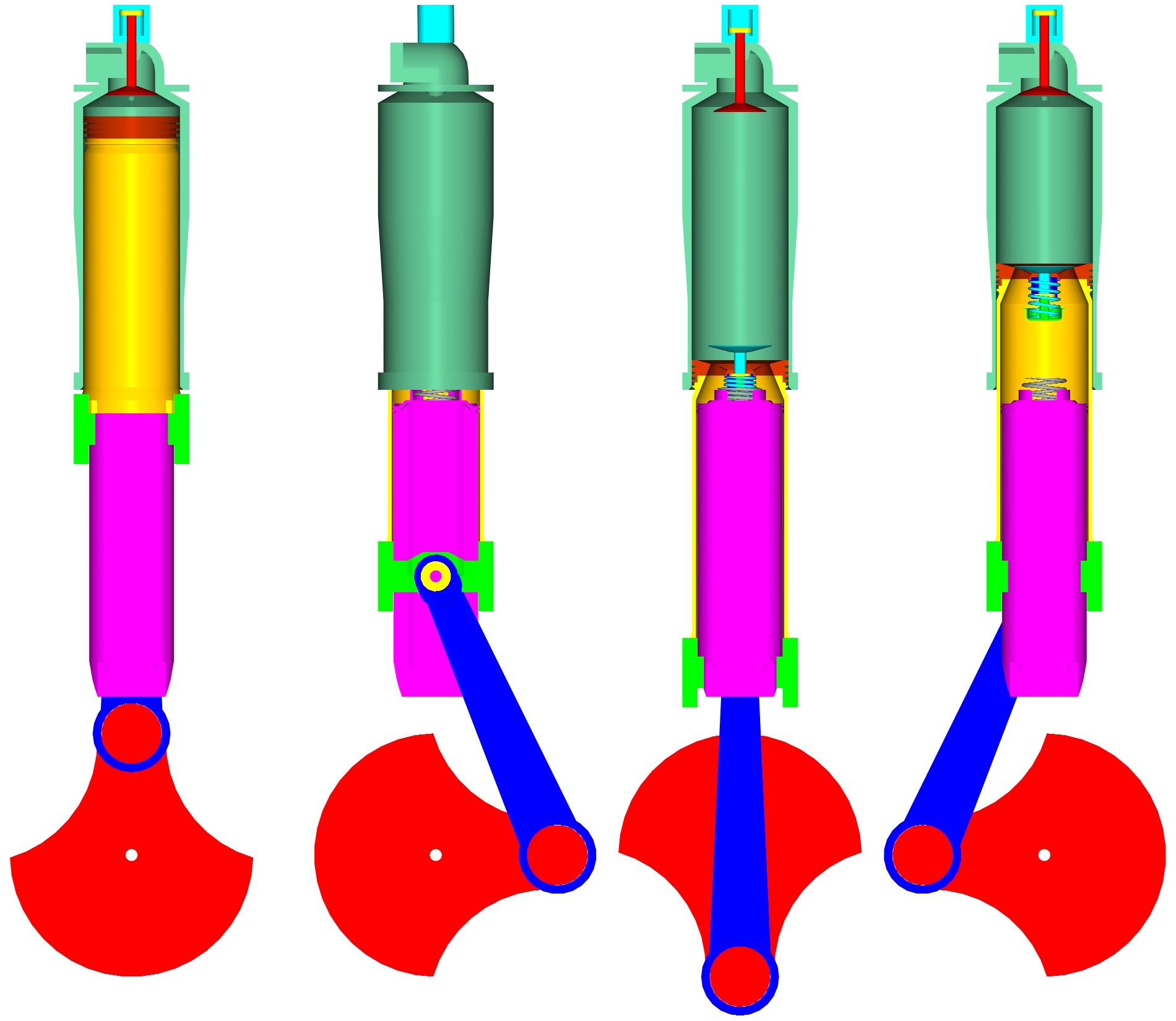

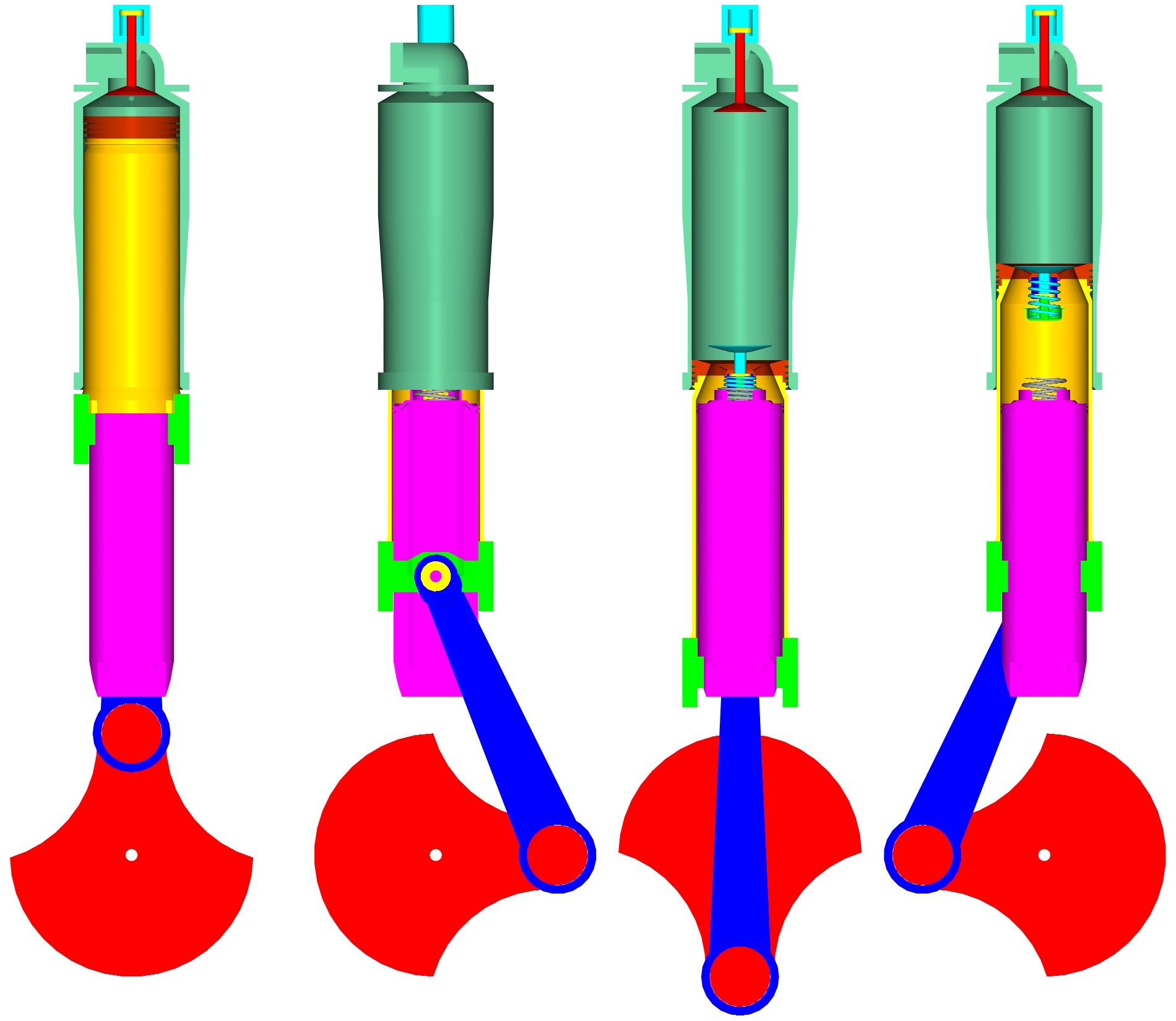

Here is a PatRoVa rotary valve for two-strokes that can eliminate this limitation of Honda’s design:

(more at

http://www.pattakon.com/pattakonPatRoVa.htm )

Thanks

Manolis Pattakos