Encouraging article if true.

Source:

http://www.motorsport.com/f1/news/techn ... es-668712/

Technical analysis: Combustion secret to Ferrari 2016 hopes

Ferrari is bullish it can start the 2016 Formula 1 season on the top step of the podium. Franco Nugnes looks at the Italian squad's plans to make the step to beat Mercedes in Australia.

Formula 1 teams well know the PR dangers that come from over-promising and under-delivering, which makes Ferrari’s recent bold statements of intent about a winning start in Melbourne intriguing.

President Sergio Marchionne is adamant that from the first race, Ferrari must be a Mercedes-beater. But is this all just wishful thinking, or does he know something that those outside the team are unaware of?

Here, we look at the design avenues that Ferrari have been looking at in a bid to overhaul the Silver Arrows, especially when it comes to closing down the horsepower deficit the Prancing Horse has faced.

Engine focus

Perhaps Marchionne's optimism of an attacking start is based on the reality of encouraging data that is coming out of Maranello, both in terms of aerodynamics and, more significantly, on the engine front.

And could it be in the latter area – with it widely accepted that much of Mercedes' dominance has been based on its brilliant power unit execution – where Ferrari has made some significant gains.

300 bar pressure

According to Motorsport.com sources, Ferrari's focus in engine development this winter – helped by an easing of development restrictions – has been on the combustion chamber of the new 059/5 V6 engine.

It is suggested that chief designer Lorenzo Sassi has pushed for an innovative direction, both in terms of packaging but also in terms of performance.

One target that has been set has been to reach a 300 bar pressure in the combustion chamber, much higher than last year's figures that were understood to be around 220-240 bar.

Operating like a diesel

Ferrari's aim is to reduce the ignition time, and make the engine operate in a similar way to a diesel with auto-combustion.

If you can get the fuel to burn before the ignition spark, through high pressure within the chamber, then that will deliver a substantial increase in power. It's easy to say but very complicated to carry out.

Variable intake trumpets

Variable trumpets assembly

Photo by: Giorgio Piola

Achieving that target can be improved by bringing fresh air inside the combustion chamber, and Ferrari has decided to optimise this area with variable geometry.

Although variable intake trumpets (PICTURED) were banned in 2014, they were allowed from last year, although Ferrari did not pursue that route initially.

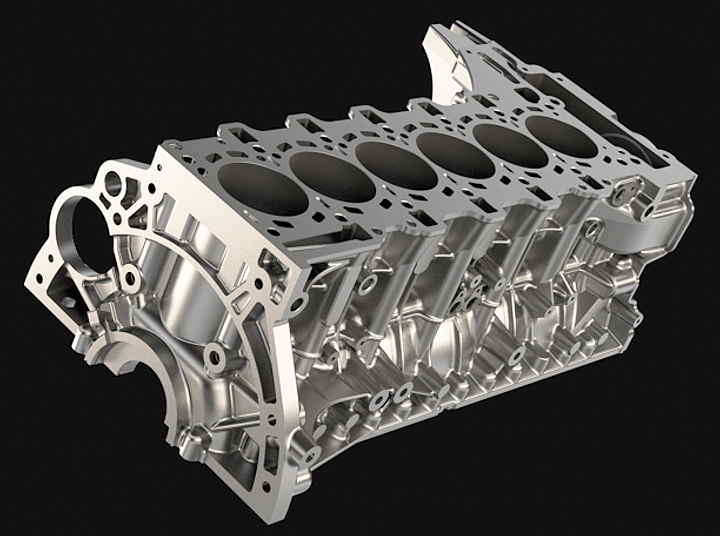

Last year, Ferrari has its compressor and intercooler between the cylinder banks (SEE MAIN IMAGE) – but these are now set to be moved to make way for the variable intake trumpets. There will also be bigger air and water intercoolers than last year.

Temperature issues

Higher pressure inside the combustion chamber to create auto combustion will obviously result in higher operating temperatures – perhaps up to 1100 degrees Centigrade.

This is why cooling has become a big focus too – especially with there being a limit of five engines for the 21 grands prix scheduled to take place this year.

Closer partnerships

Well aware of how Mercedes has made good gains through its close relationship with Petronas, so too Ferrari is working in unison with its fuel supplier Shell, to deliver a product that fits in with the characteristics it wants.

With Magneti Marelli too, there has been revisions to the injectors to ramp up the pressure to 500 bar – and a new carbon fuel pump.

Ferrari is also eager to ensure that performance gains do not compromise reliability, with engine chief Mattia Binotto having utilised facilities at AVL Graz under the supervision of Wolf Zimmermann, a specialist who brought with him knowledge from Mercedes when he joined in 2014.

Work ongoing

It is clear Ferrari is leaving no stone unturned in its bid to deliver on the high targets being set by Marchionne. With still more than one month to go before the first test, its efforts are not easing off, but the proof of its work will only come when cars hit the track for the first time.

All eyes then will be on Barcelona.

Watching F1 since 1986.